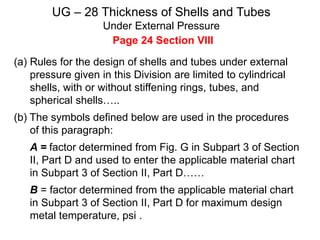

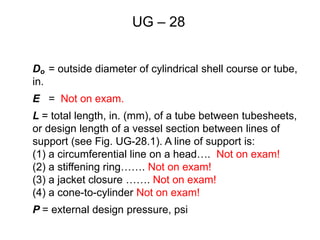

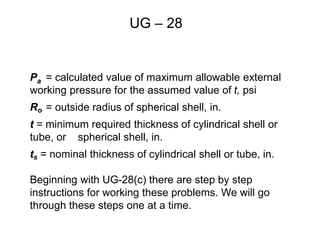

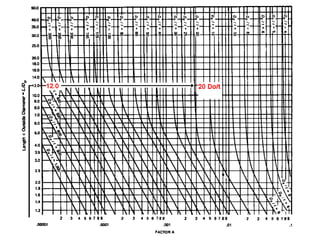

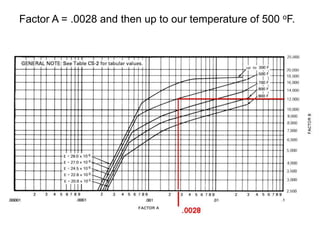

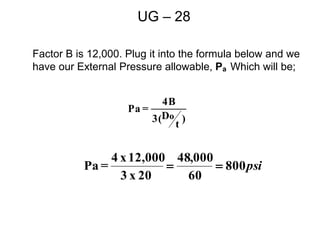

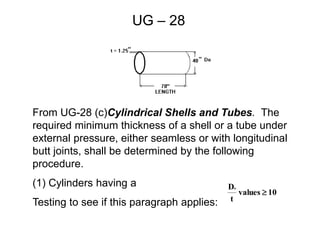

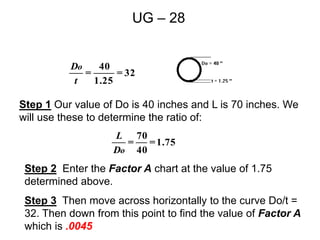

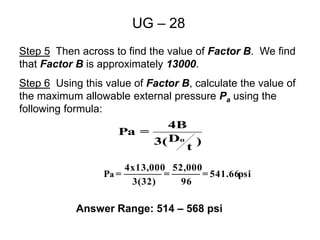

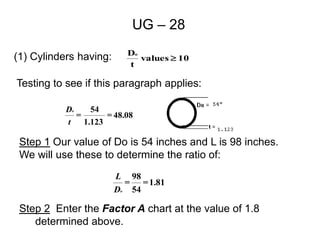

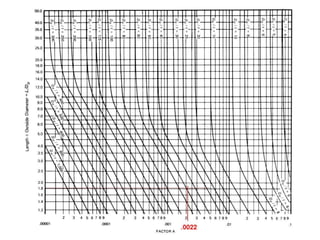

This document provides instructions for calculating the maximum allowable external pressure on cylindrical shells and tubes. It outlines a multi-step process using charts to determine factors A and B, which are then plugged into a formula to calculate the external pressure limit. An example problem demonstrates applying the steps, which are: 1) determining ratios from given dimensions, 2) using a chart to find factor A, 3) using another chart and factor A to find factor B, 4) plugging factors into the formula. The summary emphasizes that the charts and a single formula are used, with practice problems provided to illustrate the full process.