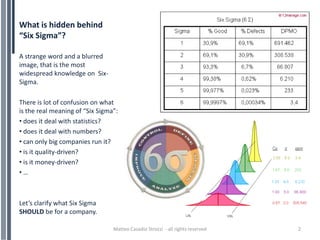

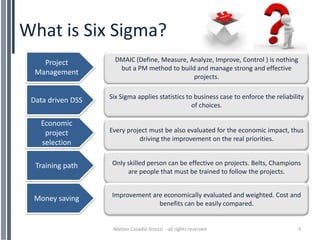

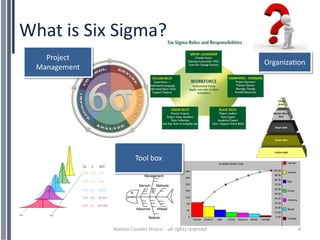

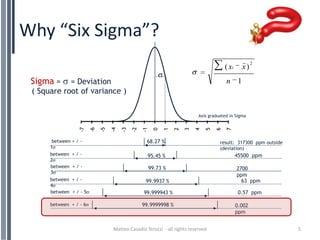

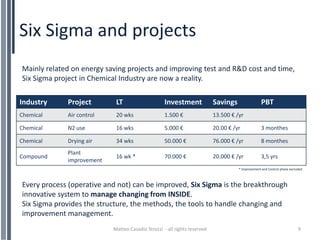

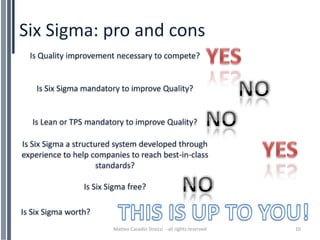

The document provides an overview of Six Sigma, a methodology used for quality management. It defines Six Sigma as a data-driven, project-based approach that applies statistics to business processes to reduce defects. Key aspects include using the DMAIC process for projects, selecting economic projects, requiring trained belts and champions to lead projects, and focusing on money savings. The goal of Six Sigma is to reduce waste and better use resources through teamwork and changes. While implementation carries some risks, Six Sigma is meant to be a flexible approach tailored to each individual company.