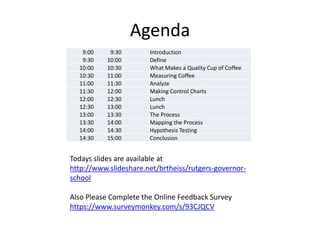

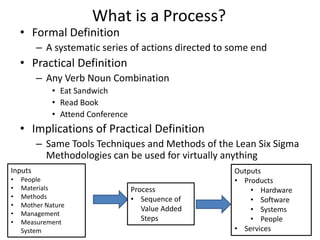

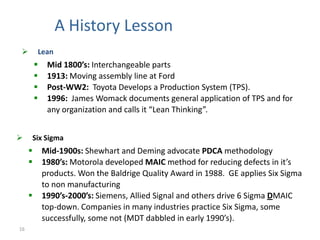

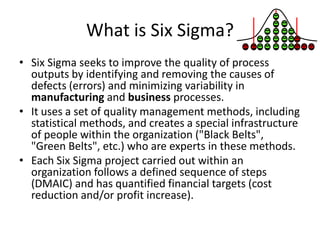

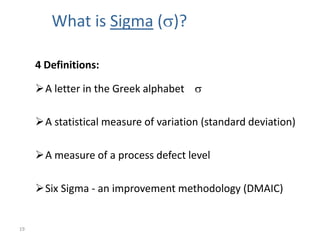

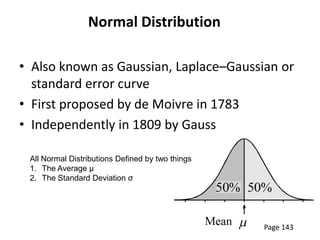

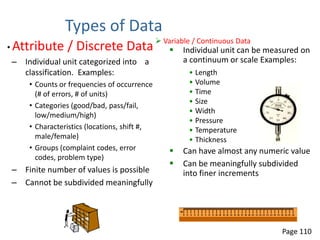

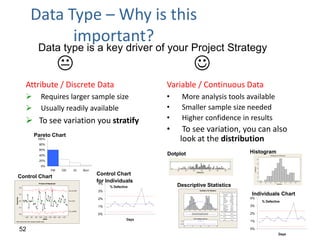

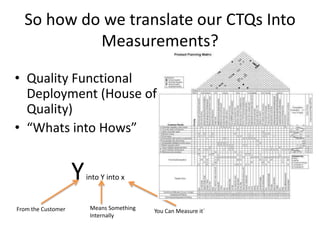

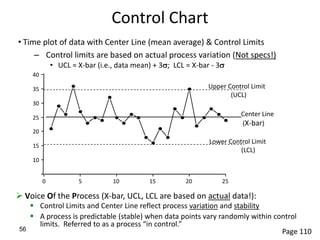

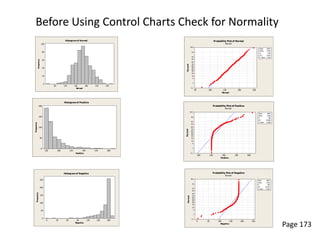

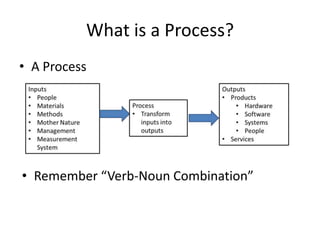

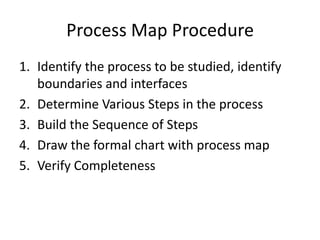

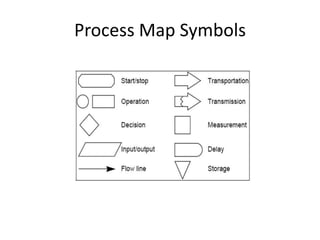

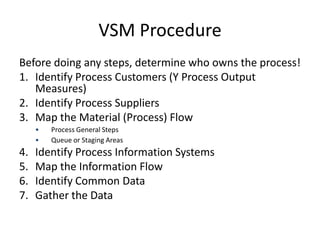

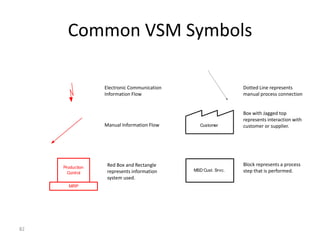

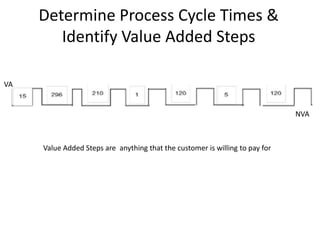

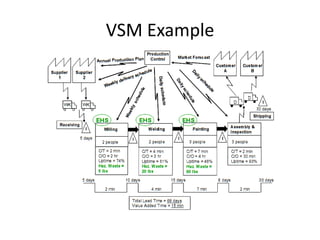

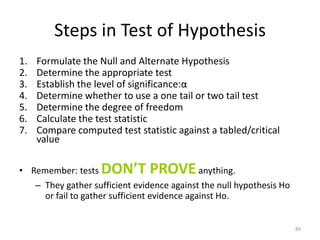

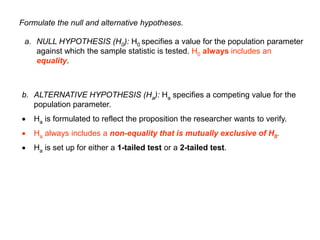

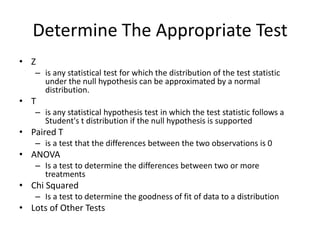

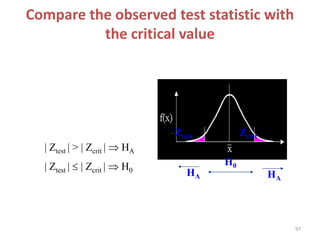

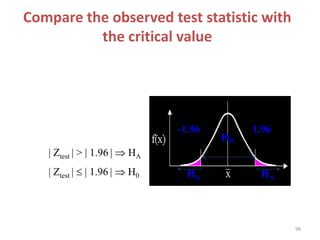

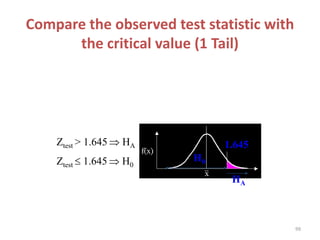

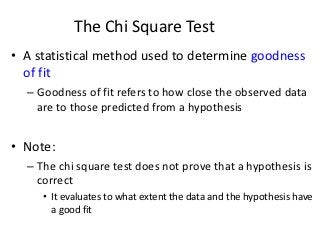

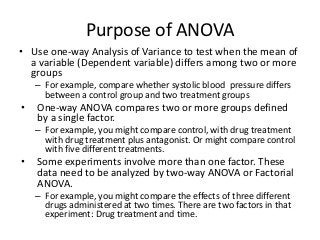

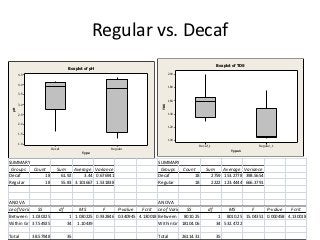

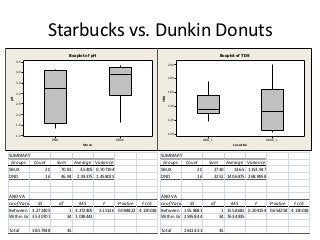

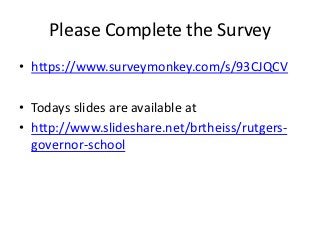

The document describes an agenda for a Rutgers Governor School event on industrial engineering and quality. The agenda includes an introduction, defining key terms, examining how to measure the quality of coffee, analyzing coffee quality data, making control charts, mapping coffee-making processes, conducting hypothesis testing, and concluding. The slides for the event are available online, as is a feedback survey.