Embed presentation

Downloaded 54 times

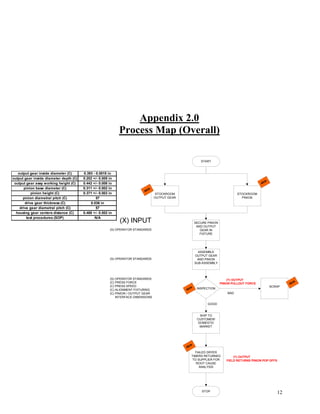

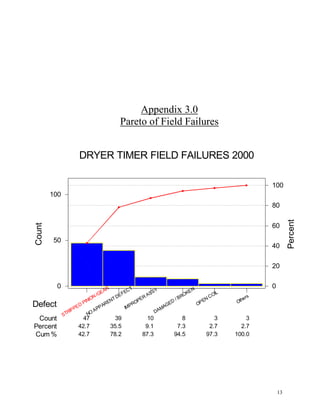

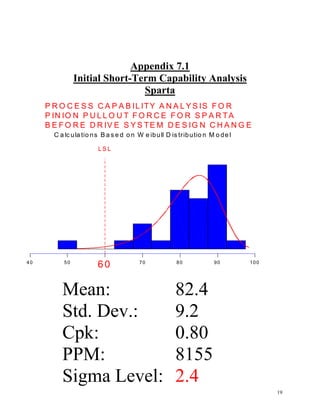

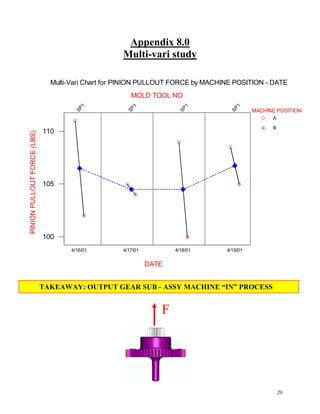

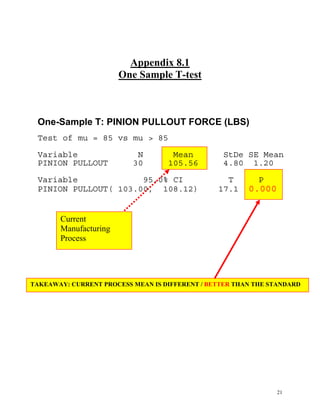

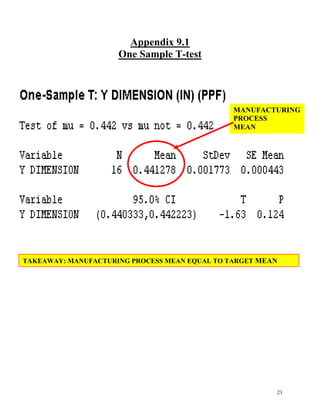

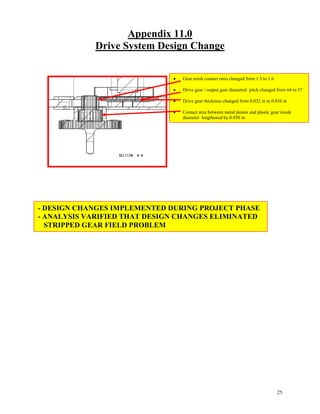

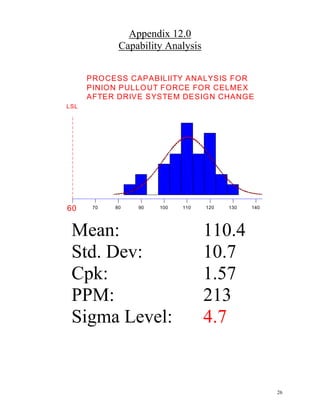

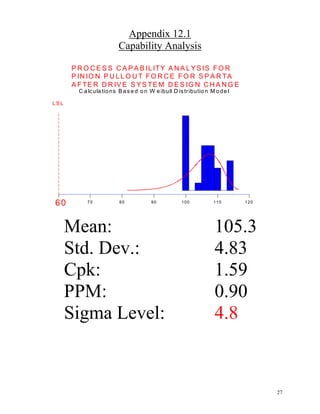

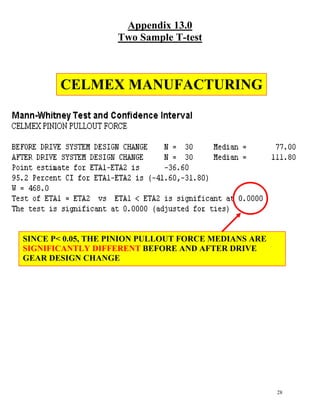

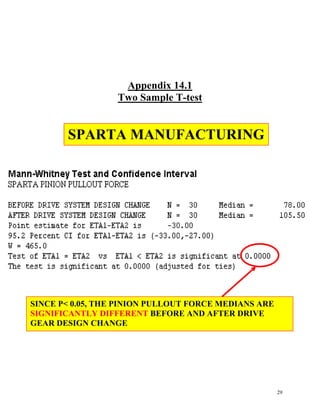

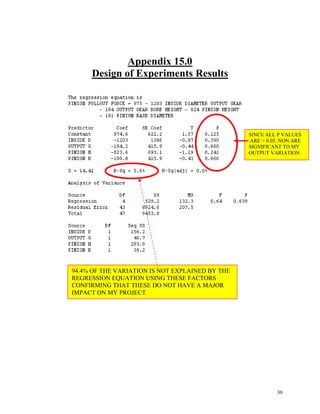

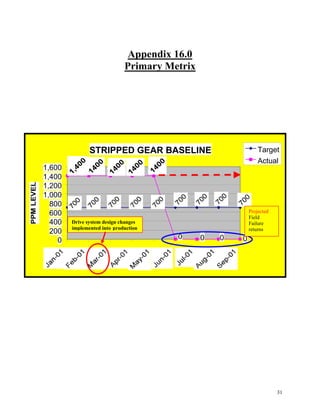

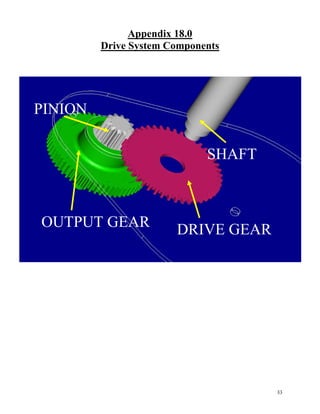

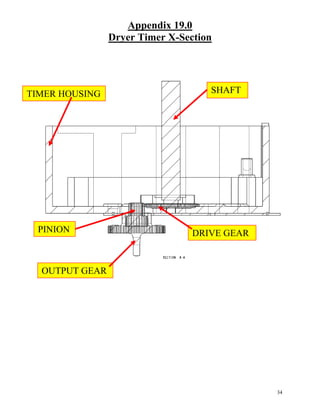

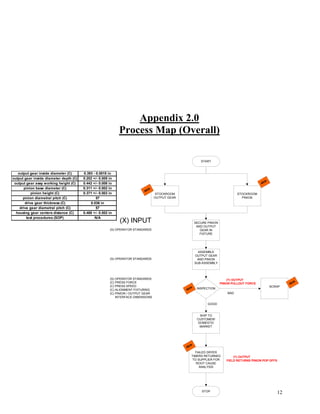

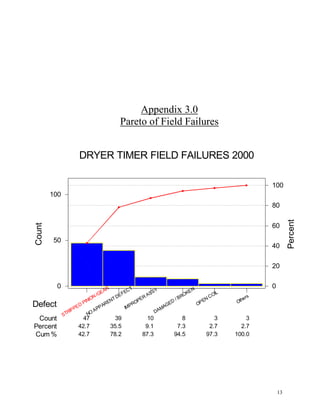

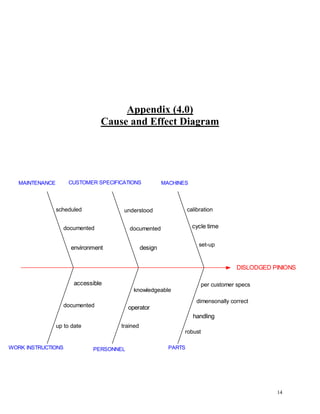

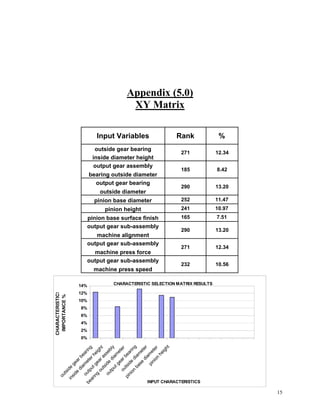

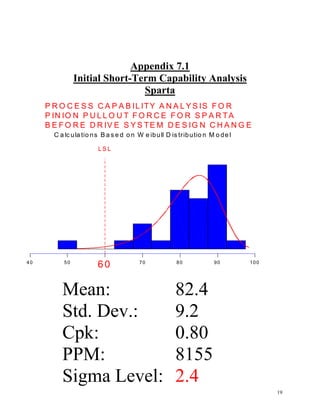

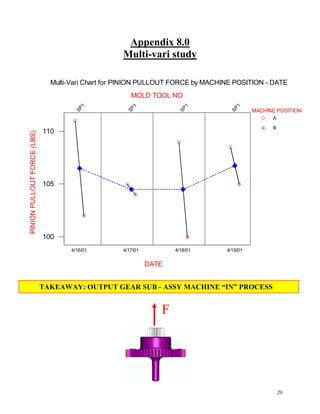

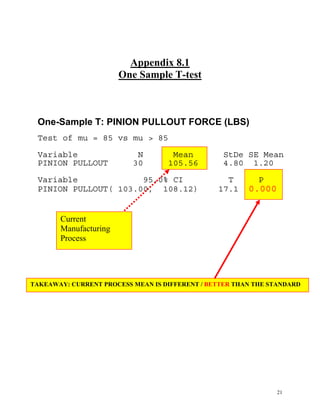

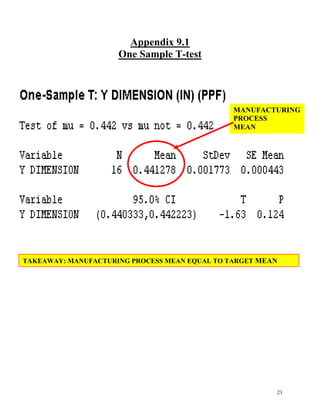

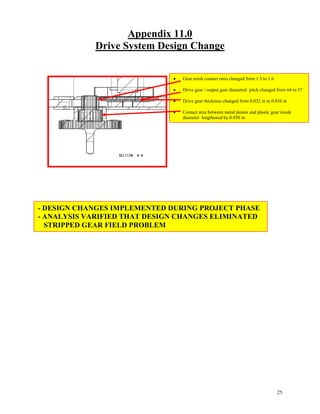

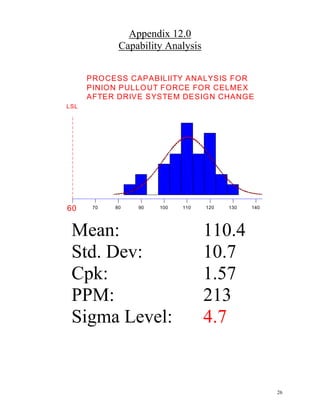

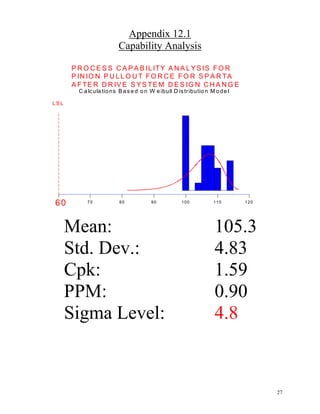

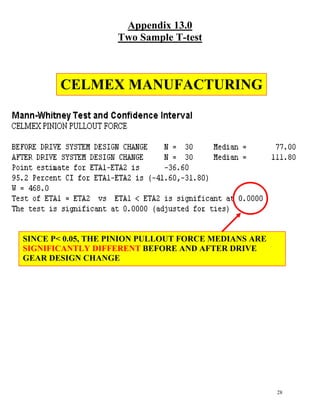

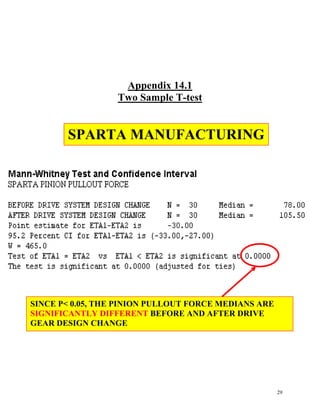

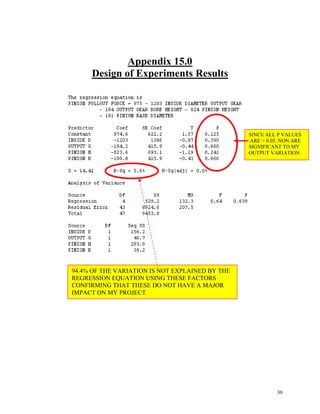

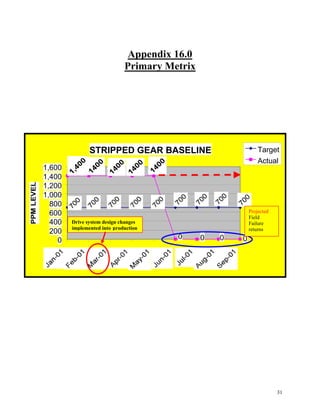

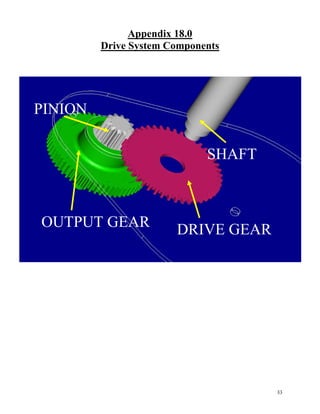

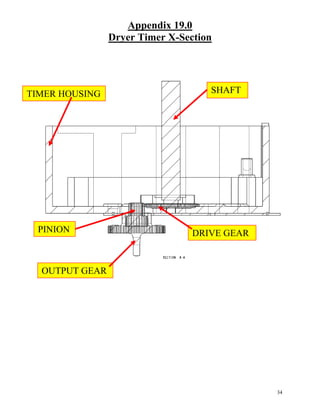

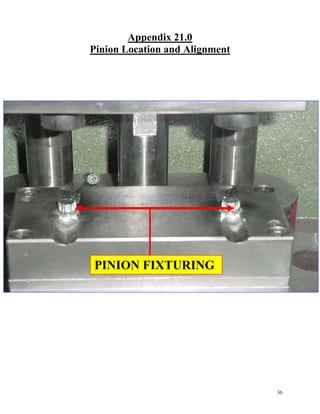

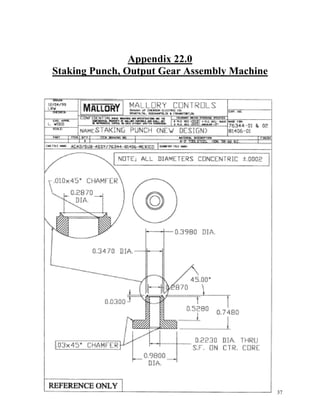

This document summarizes a project to address failures in dryer timer drives due to stripped gears. The project aimed to reduce field failures from 1400 to 700 PPM, saving $50,000. Analysis found the drive gear system was the cause of 42% of failures. Engineering changes were made and testing showed the new design eliminated stripped gears. The project achieved the goal of zero returns and 100% cost savings.