The document describes a Six Sigma project to reduce warranty claims on a Jack in the Box product called the VCT-2000. Through root cause analysis using Pareto charts and 5-why analysis, the team found the main cause of failure was the motor pin. Brainstorming ideas to address this included changing the pin material or motor. Further analysis in control phases would evaluate solutions to prevent future pin failures. The goal is to reduce warranty claims by 50% and save approximately $400,000.

![Six Sigma Project - Group 3

5

MEASURE

Root Cause Analysis

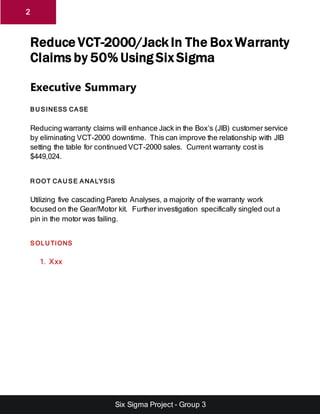

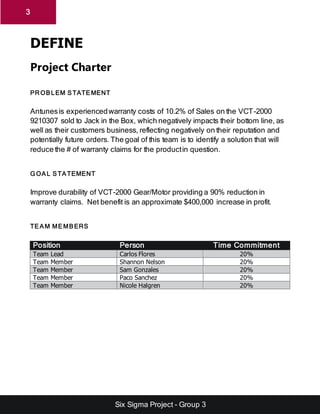

Five cascading Pareto Analyses where completed to identify that the

Gear/Motor kit neededto be replaced in a significant numberof warranty claims.

The data included all the warranty claims for the past year. We looked to see

what specific piece of equipmentcaused the most claims. It was the VCT-2000

and there were 1482 claims. Filtering outclaims by customer, the data pointed

to Jack in the Box with 653 claims. The next highestclaim customerhad only 84

claims. We continued ouranalysis and we found that 462 of the claims were due

to a damaged part. We dug deeperto see if we could identify the damaged part

and if it was done during transit. What we found out that 255 of those 462

claims had to do with the motor. We then wanted to see what specifically

neededto be done to service the motors. A final Pareto Analysis illustrated of

462 claims 255 were fixed by a gear motor kit that was broughtto the site and

installed.

Pareto Analysis

Antunes

VCT-2000

[42]

The first 8 Causes cover 81.63% of the Total Defects

VCT

HRT

HCT

ES/ESDZ

HEBT

SS

MT

DFW

MES

MS

RT

HDC

CM

CW

VZN

GST

VS

WD

DCH

CCC

SDC

HDH

UF

UTX

DCV

TBS

CTX

0%

20%

40%

60%

80%

100%

0

200

400

600

800

1000

1200

1400

1600

Cumulative%

Defects

Causes

Product Type

Vital Few Useful Many Cumulative% Cut Off %](https://image.slidesharecdn.com/2018-6sfinaldraft2-180317192413/85/2018-6s-final-draft-2-24-5-320.jpg)

![Six Sigma Project - Group 3

6

[42]

The first 4 Causes cover 83.92% of the Total Defects

JACKINTHEBOX

Chick-Fil-A

BurgerKing

CHICKFILA

popeyes

Arbys

JOLLIBEE

KFC

ARBY'S

DAIRYQUEEN

WENDYS

checkers

CHICK-FIL-A

Wendy's

Chickfil-A

BOB'S

KFCRestaurant

MCDONALDS

popeyeschicken

SONIC

0%

20%

40%

60%

80%

100%

0

100

200

300

400

500

600

700

Cumulative%

Defects

Causes

Customer

Vital Few Useful Many Cumulative% Cut Off %

[42]

The first 2 Causes cover 81.23% of the Total Defects

DamagedPart

LooseConnection

Defectivepart

Seized

GearsStripped

MaintenanceIssue

NotAdjustedProperly

By-Pass

OpenCircuit

MissingScrews

Worn/Chafed

BurntTerminal

CustomerAbuse

NoTroubleFound

Obstruction/Clogged

Unknown

AirTrapCracked

Broken/Cracked

BurntWire

ImproperInstallation

NotToSpec

Shorted

0%

20%

40%

60%

80%

100%

0

50

100

150

200

250

300

350

400

450

500

Cumulative%

Defects

Causes

Cause

Vital Few Useful Many Cumulative% Cut Off %](https://image.slidesharecdn.com/2018-6sfinaldraft2-180317192413/85/2018-6s-final-draft-2-24-6-320.jpg)

![Six Sigma Project - Group 3

7

[42]

The first 4 Causes cover 80.96% of the Total Defects

MOTOR

SWITCH,POWER

SWITCH,INTERLOCK

BEARINGS

CHAINANDSPROCKET

SPROCKET

Multiple

FAN

IdlerAssy.

MOTOR/GEAR/DRIVE

MOTORS

CONTROLBOARD

THERMOCOUPLE

BLADE,FAN

CamAssembly

OTHER

SHAFT

BRACKET

CHAIN

DOOR/DOORHINGES

HOUSING

LOCKLEVERWELDMENT

RELAY

SLIDERAIL

TENSIONER

0%

20%

40%

60%

80%

100%

0

50

100

150

200

250

300

Cumulative%

Defects

Causes

Component

Vital Few Useful Many Cumulative% Cut Off %

[42]

The first 1 Causes cover 88.58% of the Total Defects

GEARMOTORKIT230V

3RPM

BALLBEARINGKIT(2-PAK)

REPLACEMENTFANKIT

FOR

GearmotorKit

INTERLOCKSWITCHKIT

POWERSWITCH

REPLACEMENT

GearMotor

IdlerSprocket

CHAINDRIVE112LINKS

DRIVEMOTORKIT120V/9

ENDHOUSINGCOVER

GEARMOTORKIT3RPM

GEARMOTORKIT9RPM

POWERSWITCH

REPLACEMENTKIT

SPROCKET25B201/2BORE

SPROCKET/RETAINER

0%

20%

40%

60%

80%

100%

0

50

100

150

200

250

Cumulative%

Defects

Causes

Part Number

Vital Few Useful Many Cumulative% Cut Off %](https://image.slidesharecdn.com/2018-6sfinaldraft2-180317192413/85/2018-6s-final-draft-2-24-7-320.jpg)