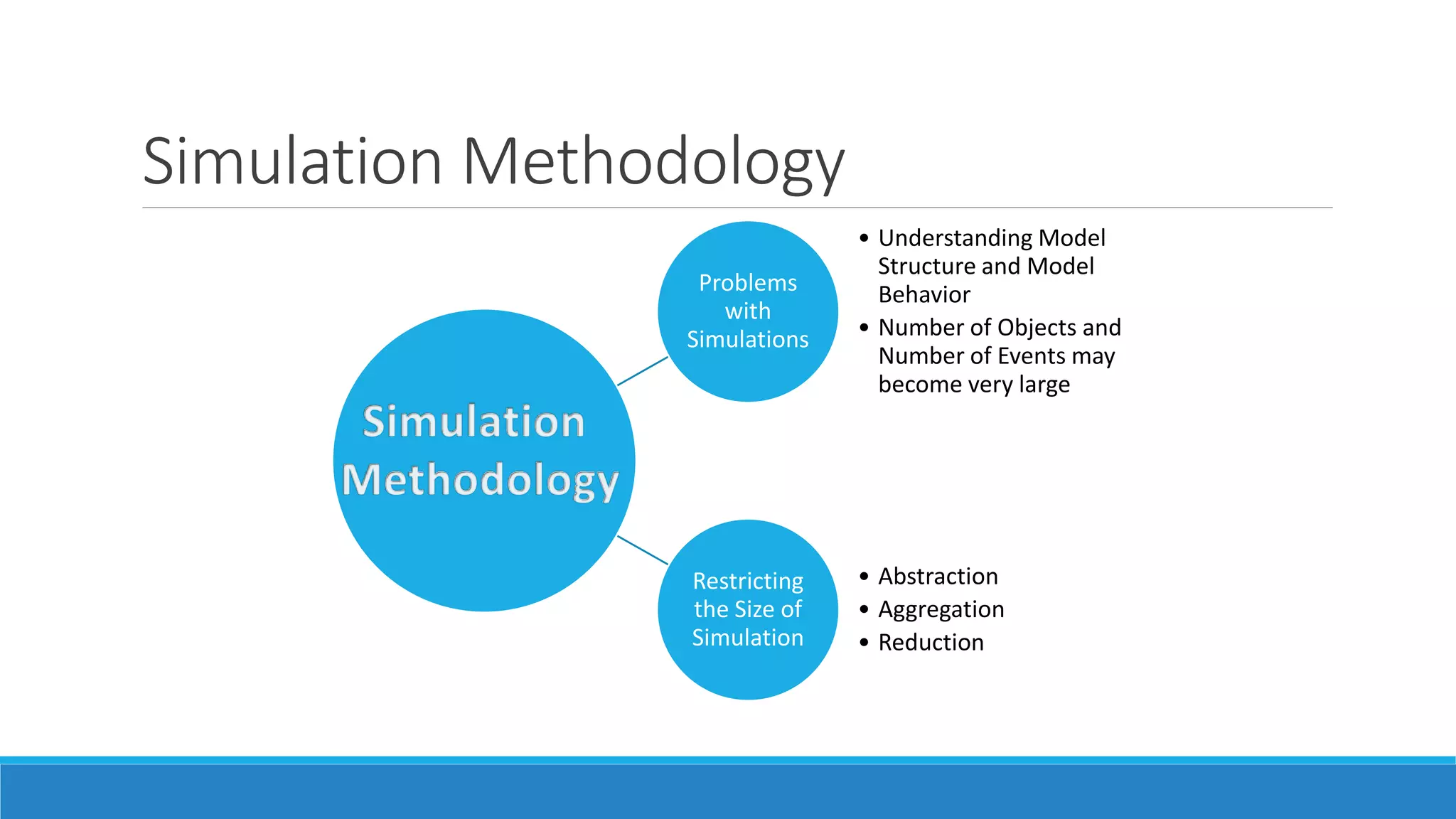

Modelling and simulation can help with supply chain management in three key ways:

1. It allows companies to evaluate supply chain performance and identify areas for improvement through analytical methods, physical experimentation, and Monte-Carlo simulation.

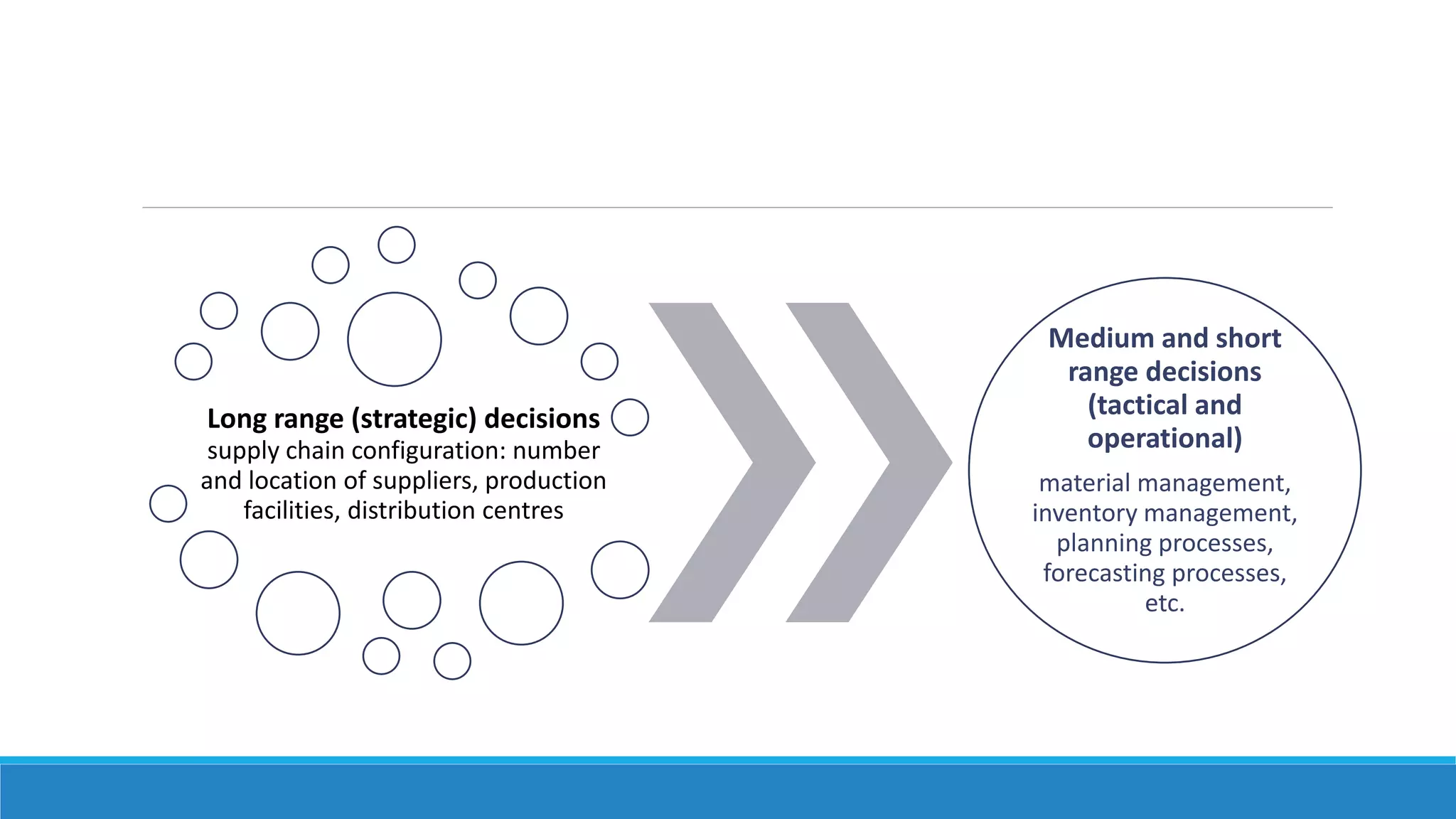

2. Simulation enables "what if" analysis to help with strategic design decisions around supply chain configuration and control policies.

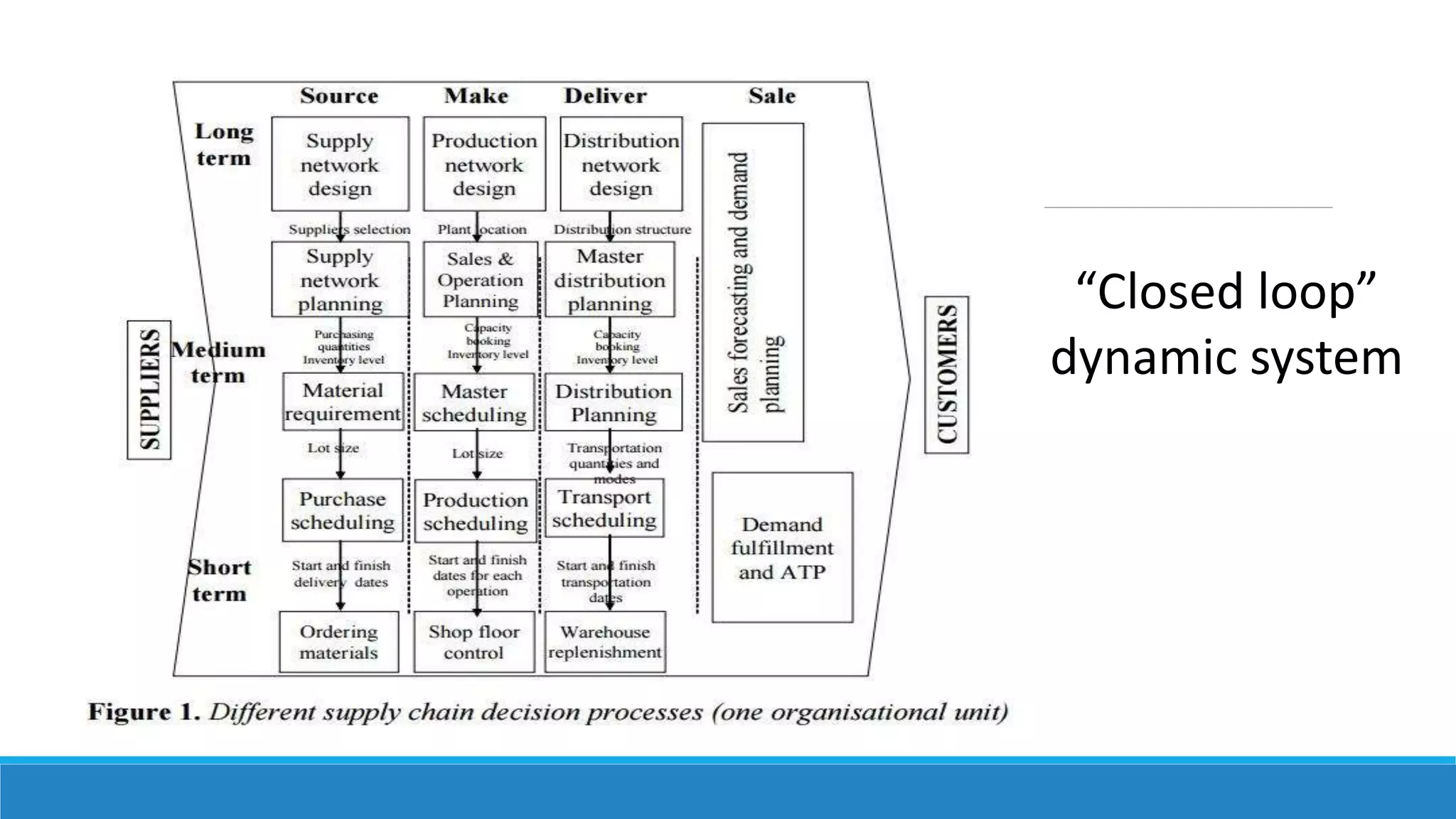

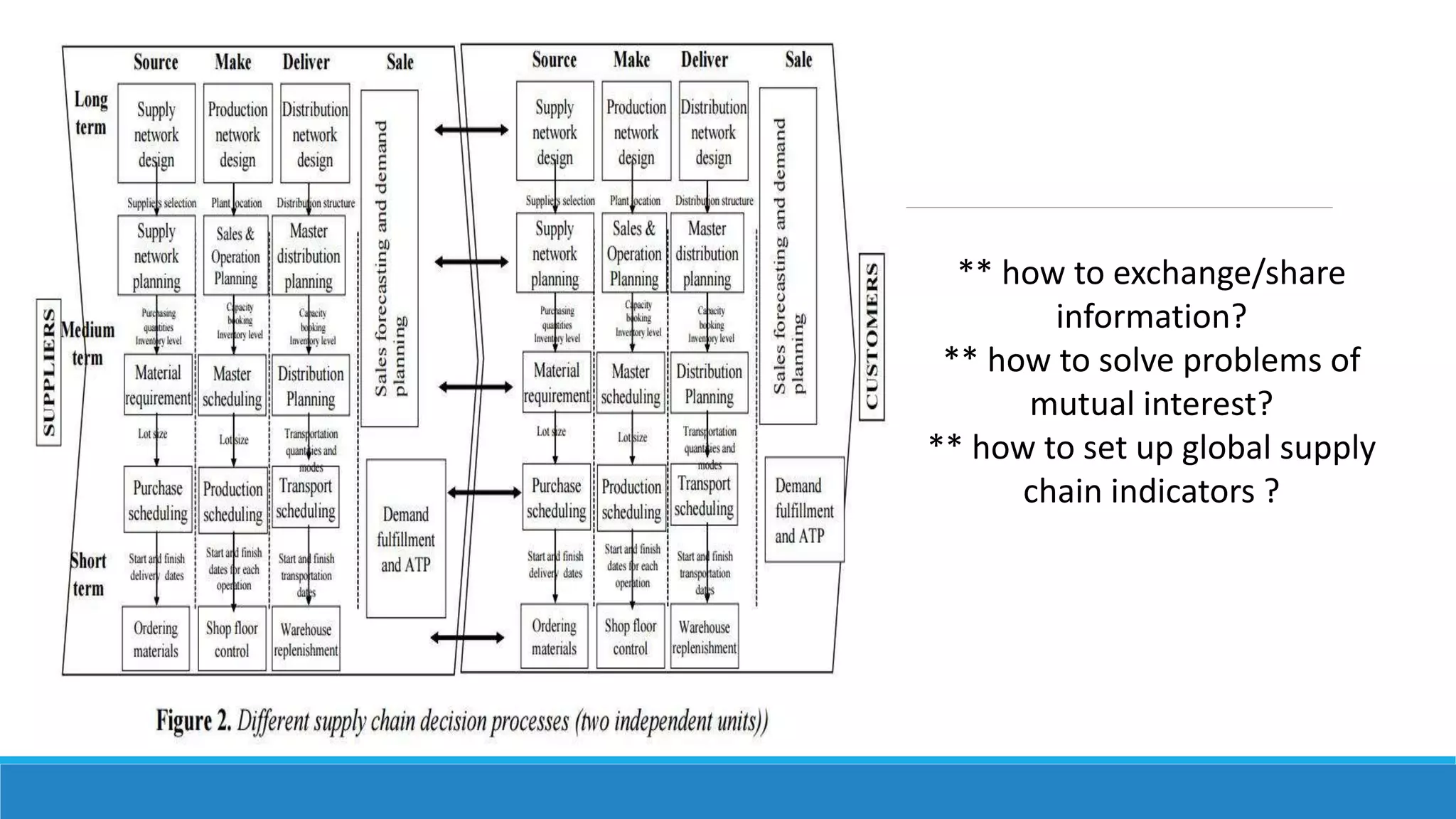

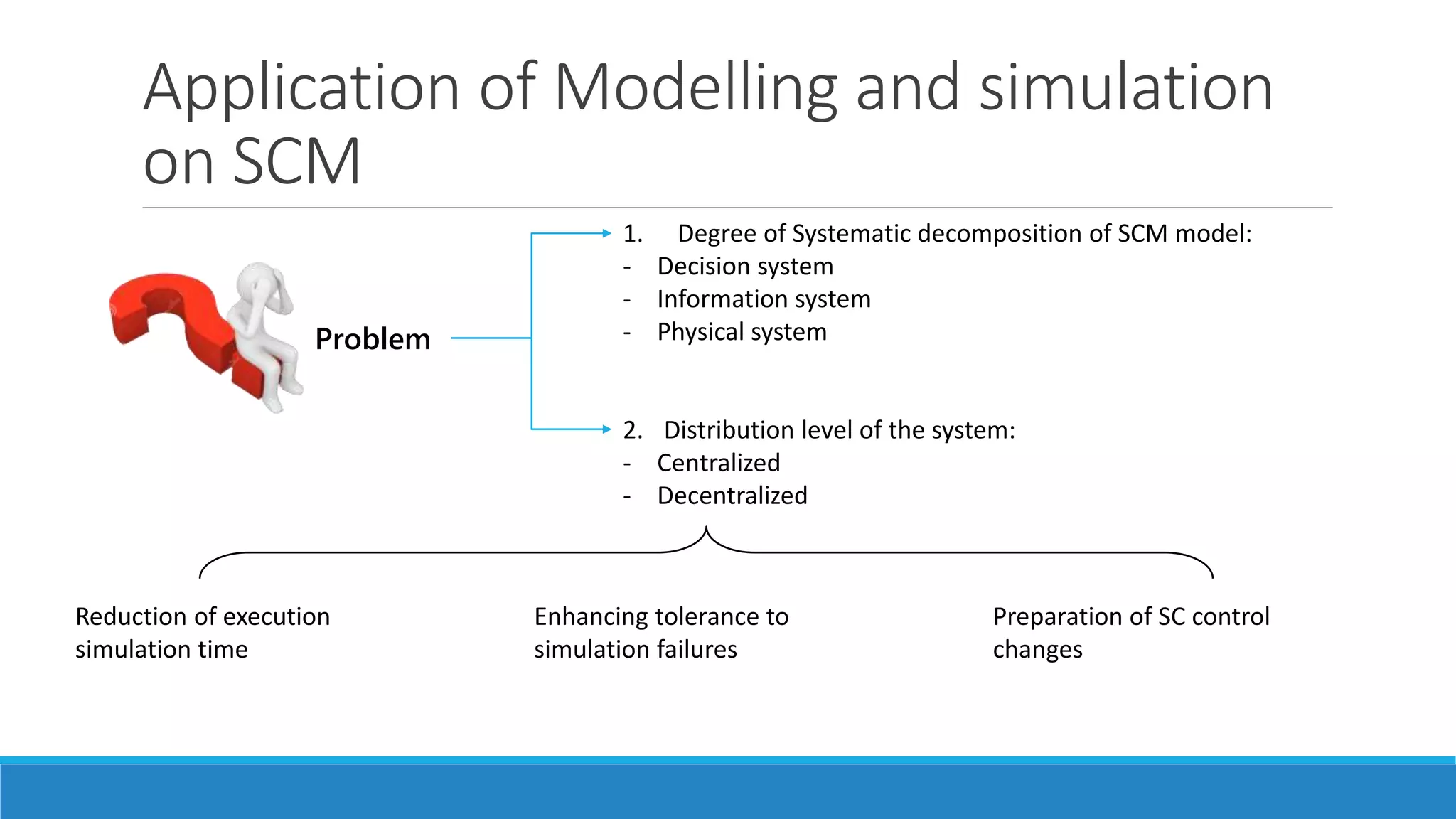

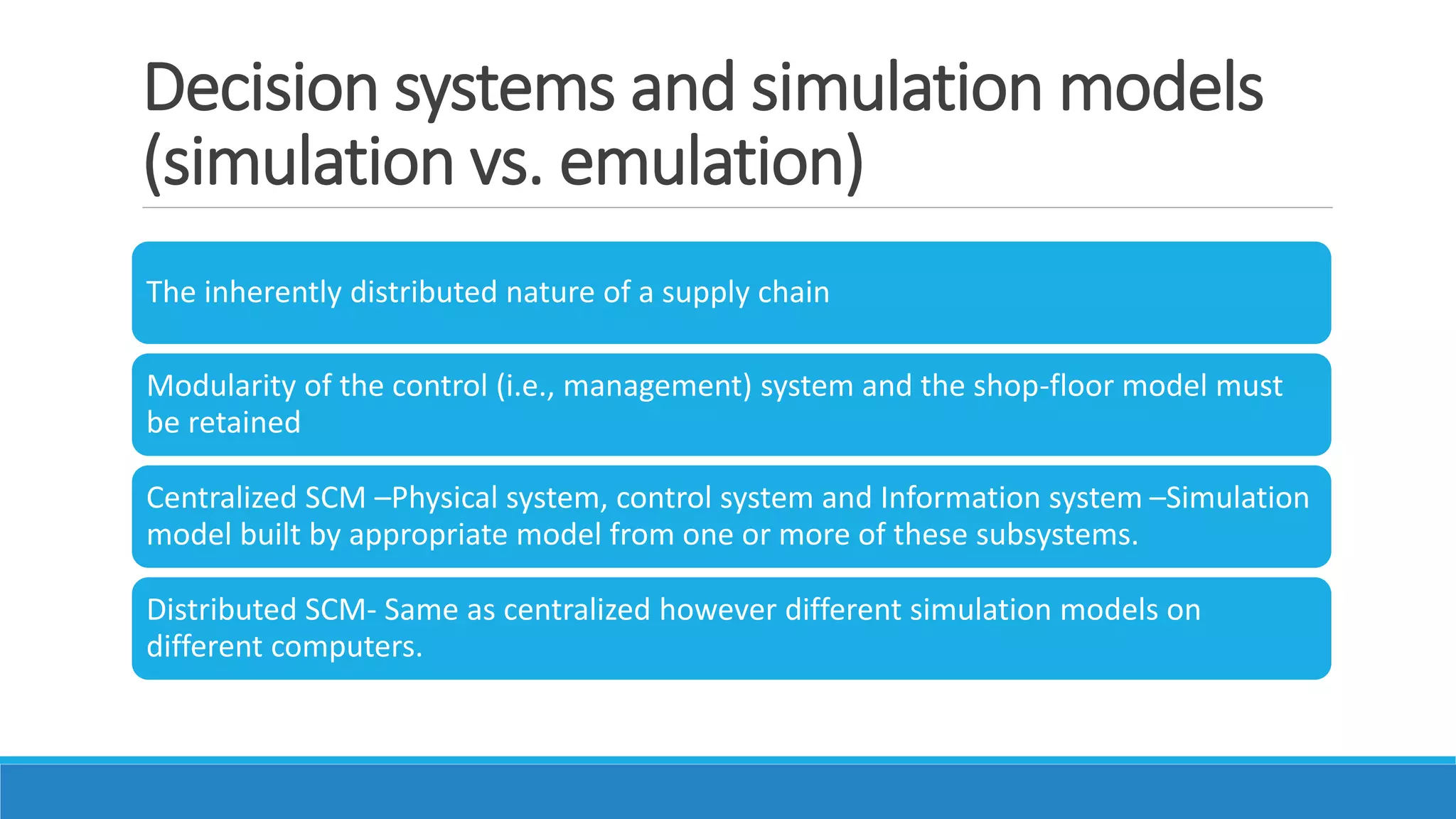

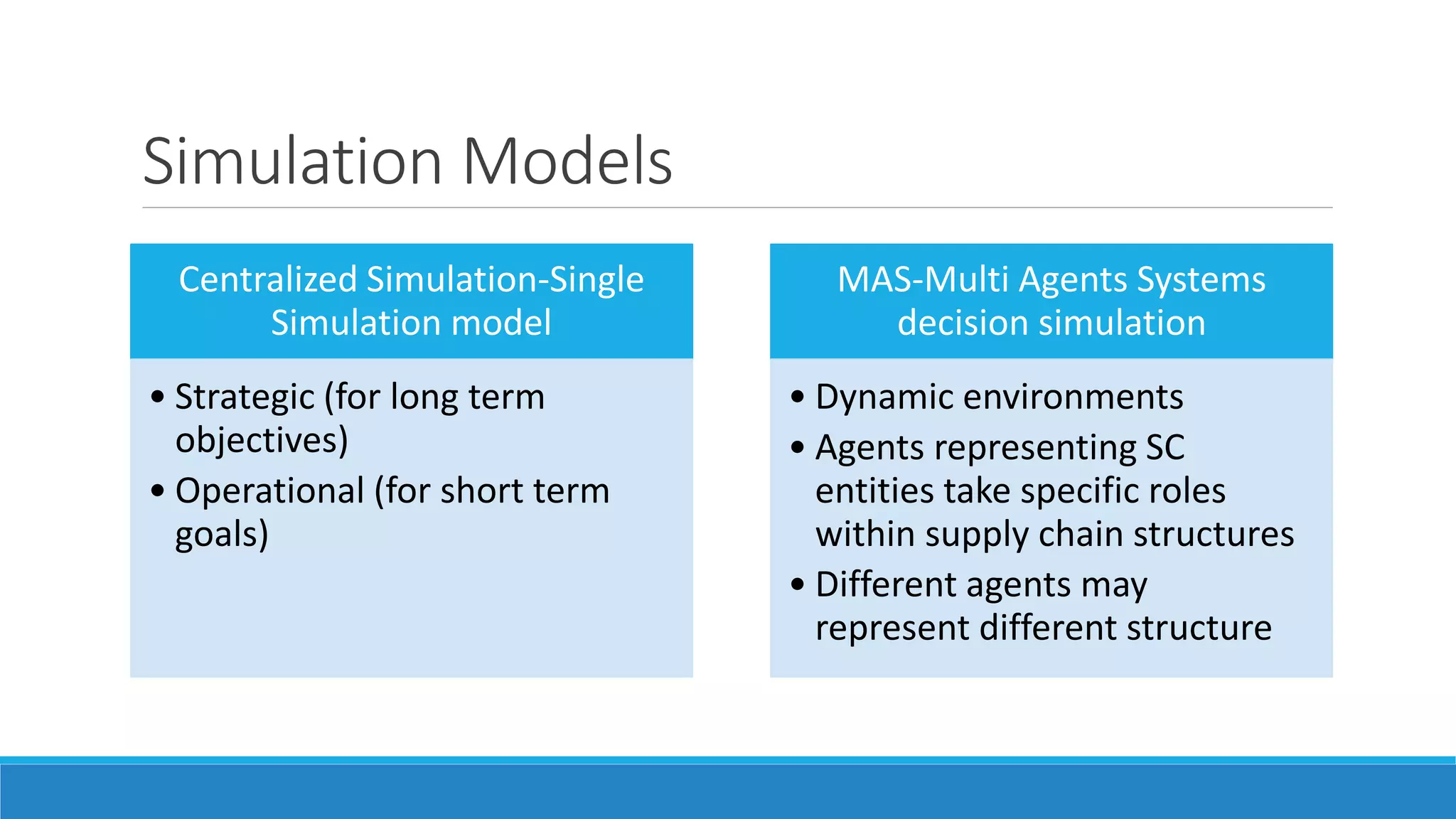

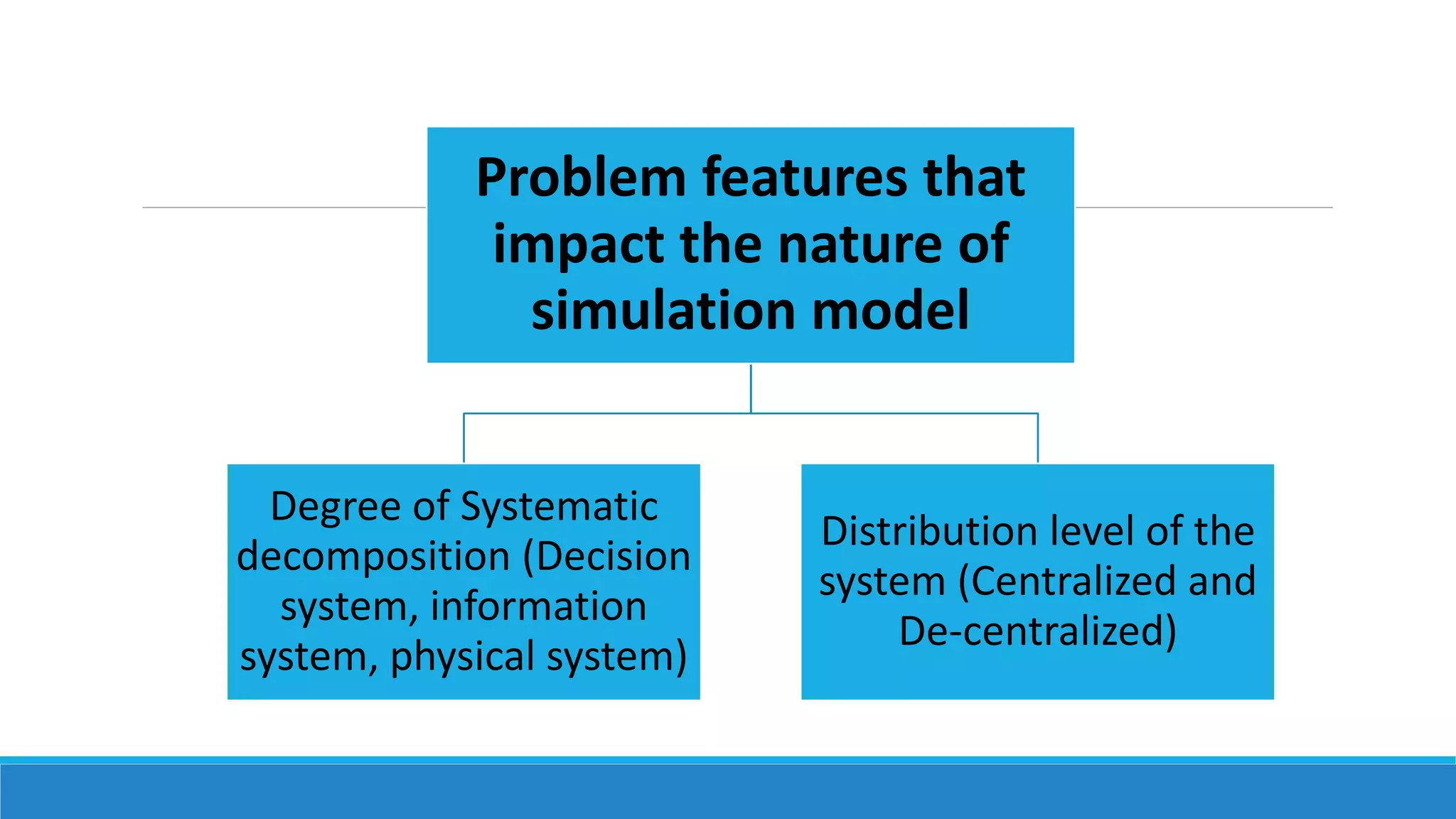

3. Both centralized and decentralized simulation approaches can be used, with the latter reflecting the distributed nature of modern supply chains running across multiple organizations.