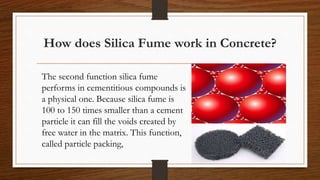

Silica fume is a finely-divided mineral admixture that fills voids between cement particles, resulting in very dense concrete with high compressive strength and low permeability. It works by filling voids created by water in the concrete matrix through particle packing. Advantages include lower permeability, higher strength, improved durability, reduced alkali-silica reactivity, and improved resistance to attack. It is used to produce high strength, corrosion resistant, and abrasion resistant concrete, as well as products like sewer pipes.