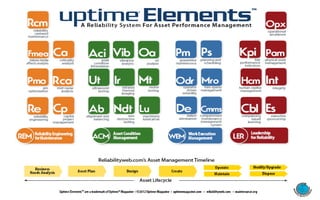

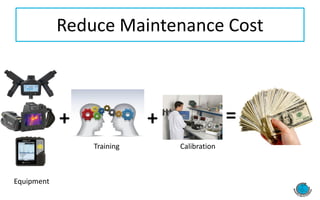

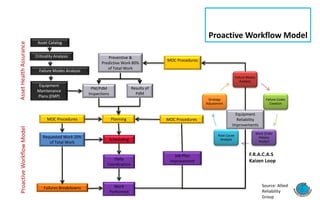

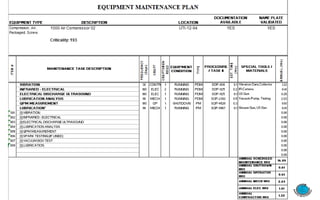

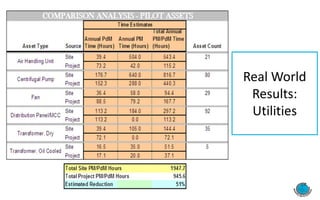

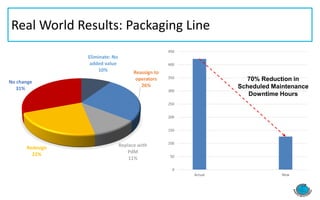

This document discusses condition-based maintenance (CBM) and how implementing a proactive workflow model focused on CBM can help organizations achieve objectives like increasing equipment availability and reducing maintenance costs. It presents dramatizations of meetings from 1990 and 2015 where organizations discuss how to address these objectives with less failures and resources. The proactive workflow model incorporates things like failure mode analysis, preventative maintenance inspections, and root cause analysis to perform mostly predictive and preventative work. Real-world results from utilities and packaging lines show significant reductions in scheduled downtime hours and maintenance costs when implementing this CBM-focused approach.