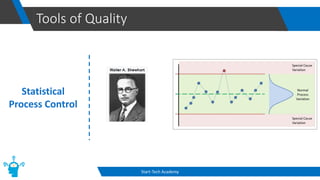

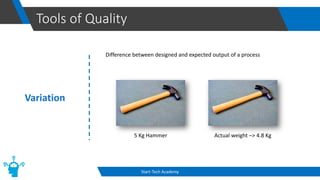

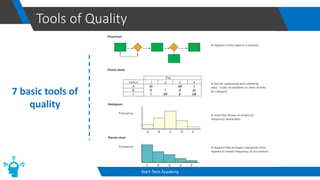

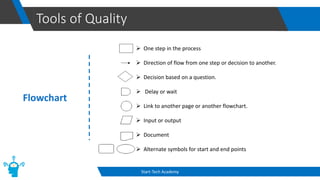

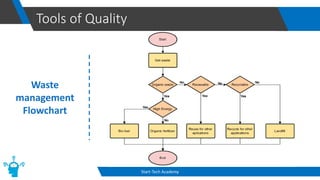

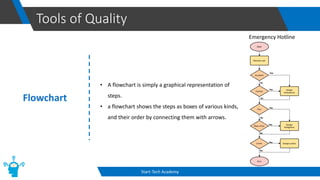

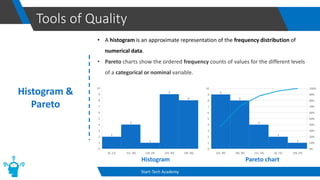

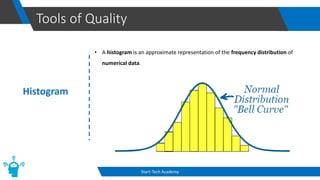

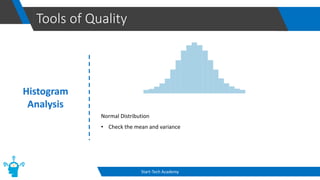

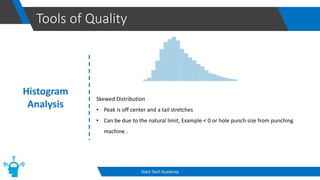

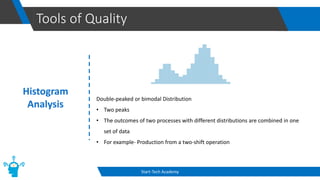

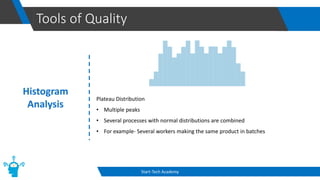

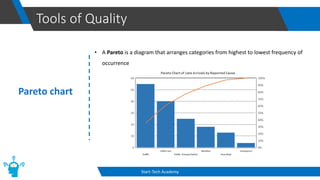

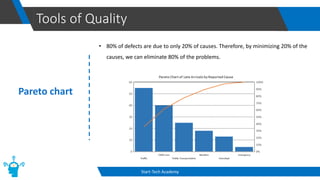

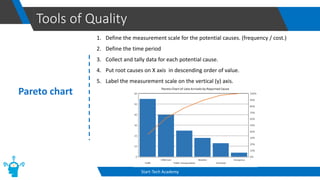

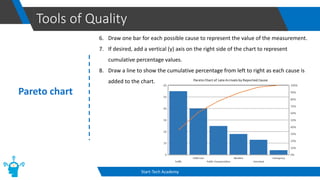

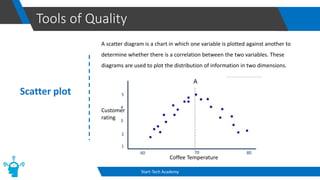

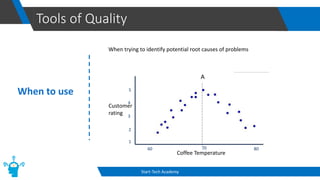

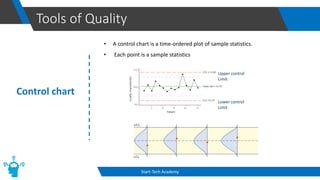

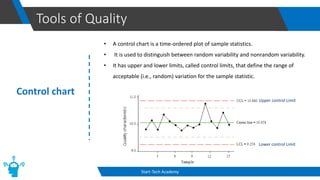

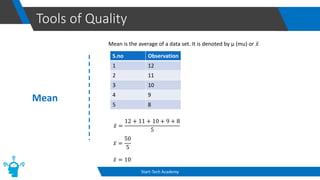

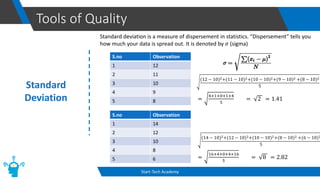

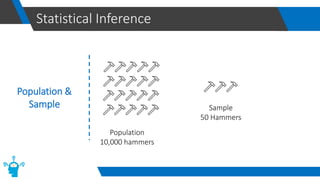

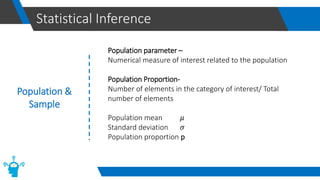

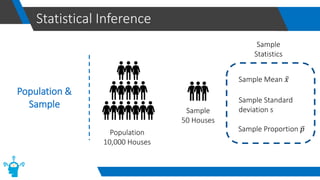

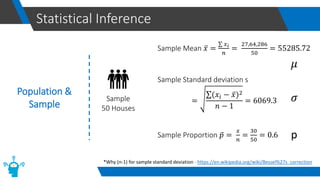

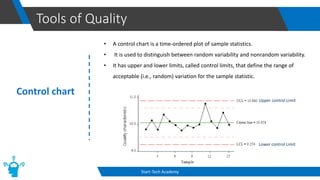

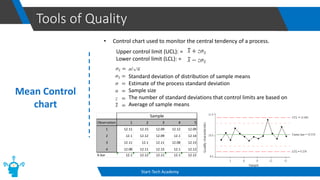

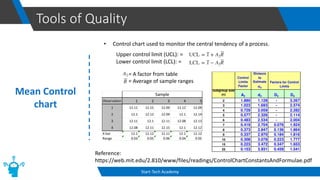

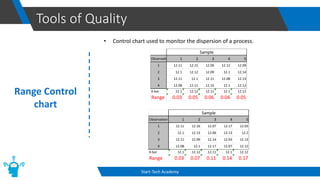

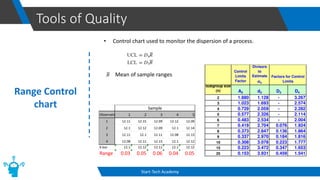

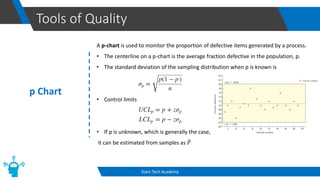

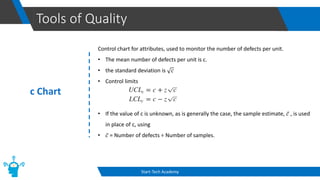

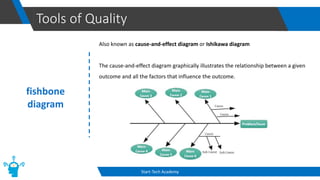

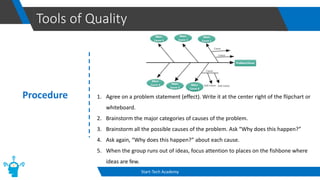

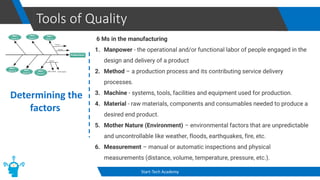

The document provides an overview of quality tools and concepts. It defines quality, processes, systems, variation and different quality tools including flowcharts, histograms, Pareto charts, scatter plots, control charts. It explains how to create and interpret these tools. Control charts are discussed in more detail with examples of mean and range control charts showing how to establish control limits and monitor process performance over time. The document serves as an introduction to statistical process control tools for quality improvement.