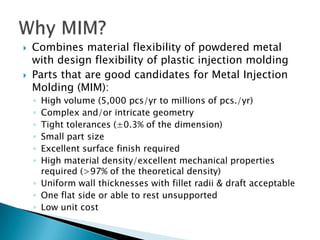

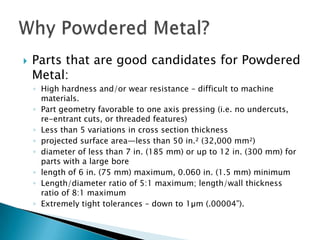

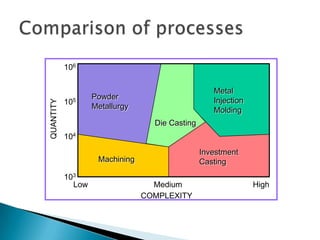

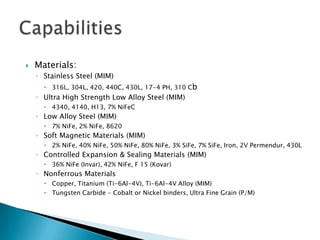

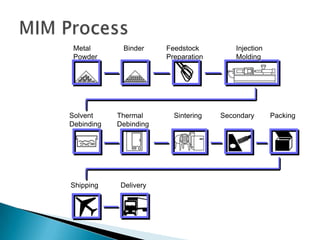

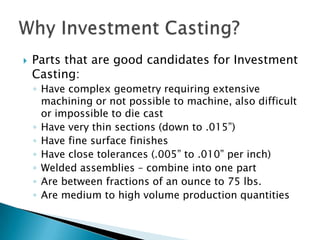

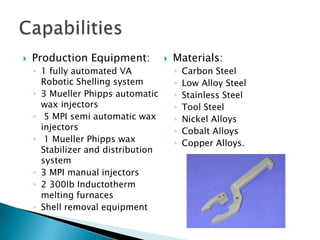

Sessions Co., LLC is a manufacturer's representative that represents several precision manufacturing companies including: B W Mfg. Co. for CNC machined products; Crown Mfg. Co. for injection molded plastic products; IMC-Microtool for metal injection molded and powdered metal products; and Lamothermic for ferrous investment cast products. These companies offer services such as CNC machining, plastic injection molding, metal injection molding, powdered metal pressing, and investment casting to produce complex parts for industries such as aerospace, automotive, medical, and more. Sessions Co. provides sales and customer support for these precision manufacturing partners.