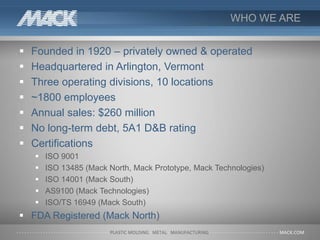

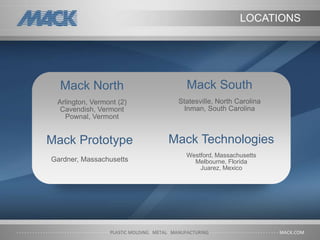

Mack is a full-service contract manufacturer specializing in custom injection molding, metal fabrication, and electronic contract manufacturing, with over 1800 employees and annual sales of $260 million. Founded in 1920 and headquartered in Arlington, Vermont, the company operates multiple facilities across the U.S. and Mexico, offering a range of design and development services, as well as advanced manufacturing capabilities in various industries, including medical, transportation, and consumer goods. Mack holds several ISO certifications and is FDA registered, ensuring compliance with rigorous quality standards.