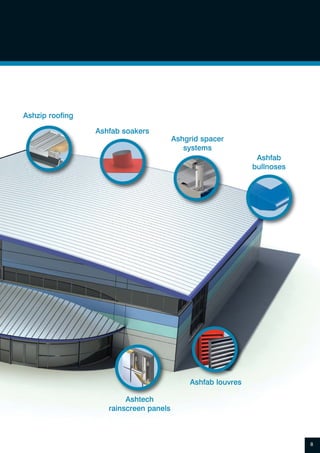

This document provides information about Ash & Lacy, a company that specializes in architectural fabrications and flashing solutions. It discusses Ash & Lacy's commitment to fast and accurate service through its nationwide network of depots. It also outlines the company's extensive product range, materials, and fabrication capabilities to meet complex architectural needs.