This document provides information about Best Technology Co., Ltd., including:

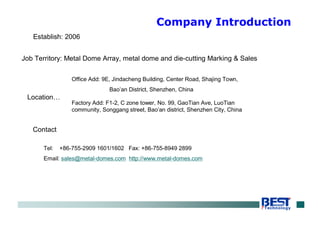

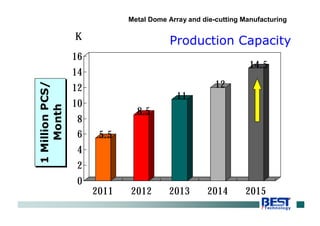

- The company was established in 2006 and is located in Shenzhen, China, specializing in metal dome arrays and die cutting.

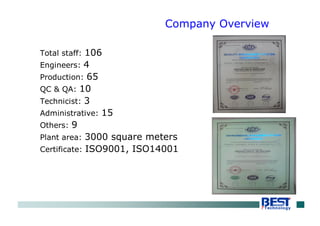

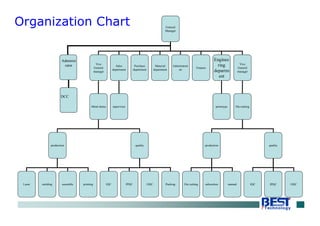

- It has over 100 employees and 3000 square meters of factory space, with ISO certifications for quality management.

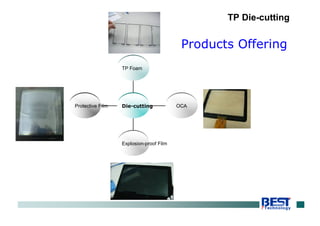

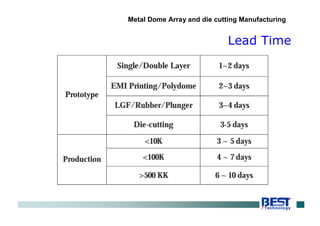

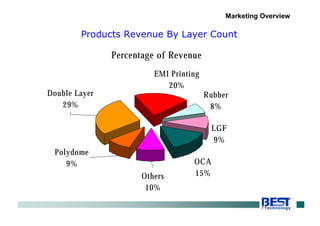

- The company offers a variety of metal dome array and die cutting products and services for industries like mobile phones and electronics.

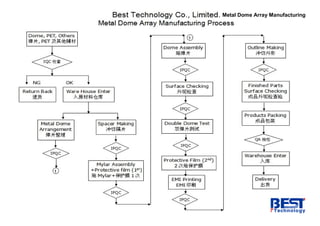

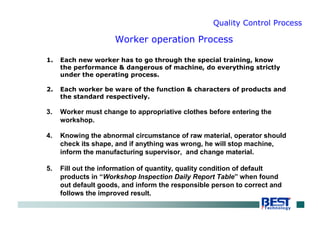

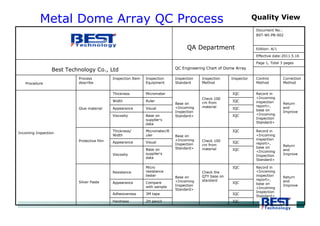

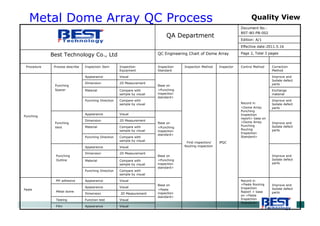

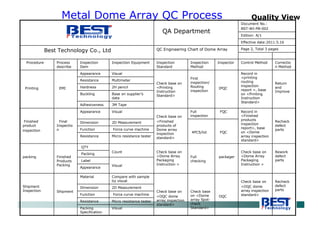

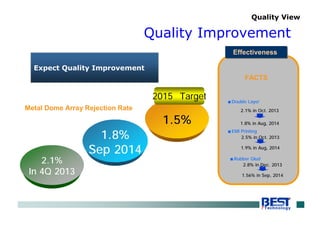

- It describes the production process and quality control procedures to ensure high quality products and customer satisfaction.