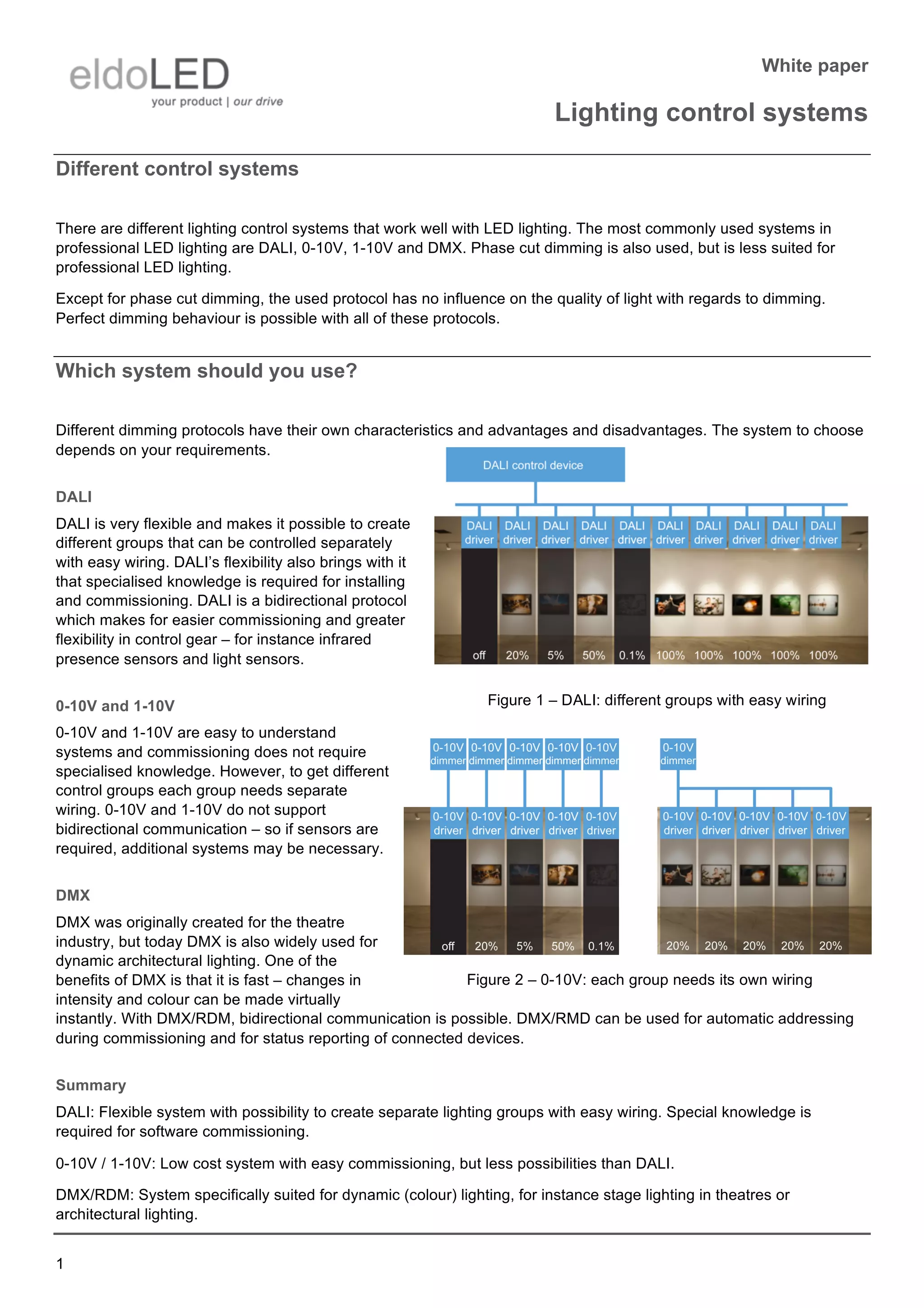

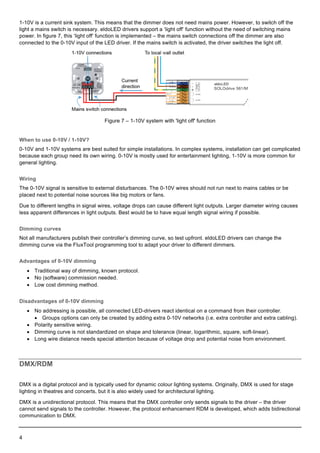

DALI, 0-10V, 1-10V, and DMX are common lighting control systems that work well with LED lighting. DALI is the most flexible system, allowing for separate lighting groups with easy wiring but requiring specialized knowledge for commissioning. 0-10V and 1-10V are low-cost systems with easy commissioning but less flexibility than DALI. DMX is well-suited for dynamic stage lighting and can provide fast changes in intensity and color. The best system depends on a project's specific requirements.