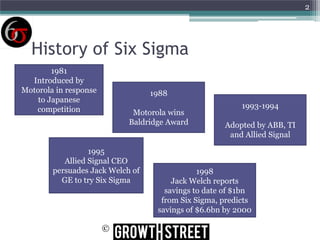

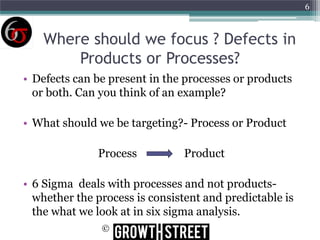

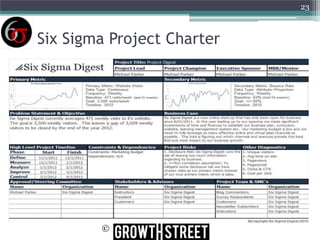

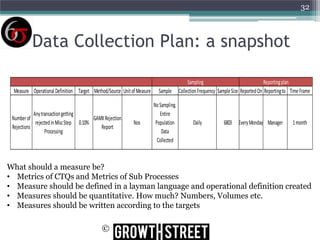

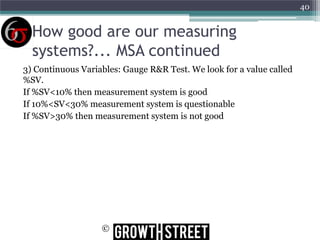

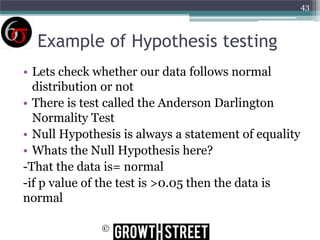

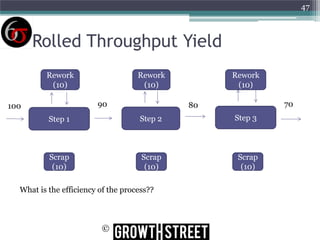

This document provides an introduction and overview of Six Sigma. It begins with a brief history of Six Sigma, noting its origins at Motorola in 1981 in response to Japanese competition. It then discusses some key Six Sigma concepts, including that it is a highly disciplined process to develop near-perfect products and services, it aims for 3.4 defects per million opportunities, and that it is a philosophy, statistical measurement, business strategy, and project management framework. The document then covers some differences between Six Sigma and traditional business excellence approaches. It also provides definitions of some common Six Sigma terms. Finally, it discusses the Define, Measure, Analyze, Improve, and Control project framework and causes and effects analysis tools used in Six Sigma