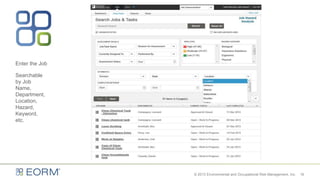

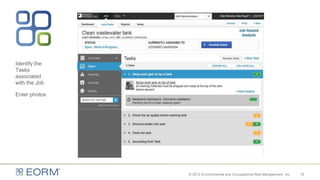

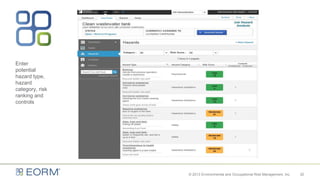

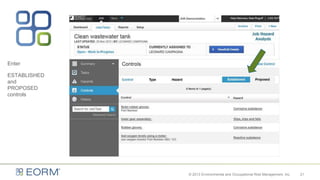

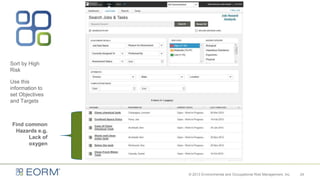

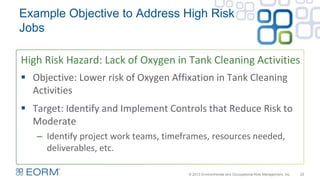

This document discusses leveraging technology to improve environmental, health, and safety (EHS) management systems planning and objective setting. It outlines the key planning steps in ISO 14001 and OHSAS 18001, including identifying hazards/risks and establishing objectives. Common challenges with consistency and change management are noted. The presentation then shows how a risk assessment software can help by standardizing data collection, prioritizing controls, and analyzing their effectiveness. Setting objectives to address common high risks across jobs is demonstrated. Using technology can virtually eliminate process failures and demonstrate compliance while reducing administration time and risk.