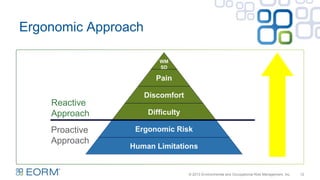

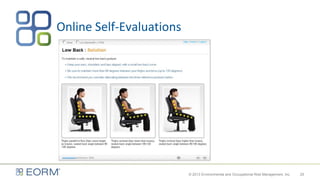

This document discusses how technology can help make an organization's ergonomics program more efficient, effective, and measurable. It recommends a three-tiered approach: online self-evaluations and training, remote support like phone evaluations with pictures or video calls when needed, and in-person support. Technology allows for automated risk identification, engagement of employees, centralized equipment data, and outcome measurement through data analysis. The goal is to manage ergonomic risks proactively rather than just reacting to injuries.