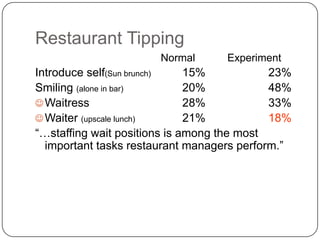

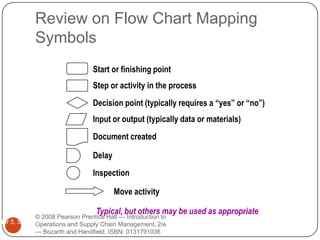

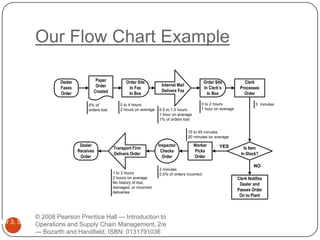

This document discusses key differences between services and goods, as well as approaches to service design and delivery. It notes that services involve both tangible and intangible components and are experienced rather than consumed. Effective service management requires consideration of marketing, personnel, and various forms of customer contact. The document also presents frameworks for mapping different types of service systems and applying concepts from behavioral science to improve customer experience.