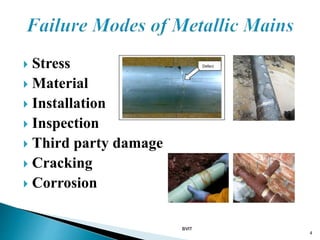

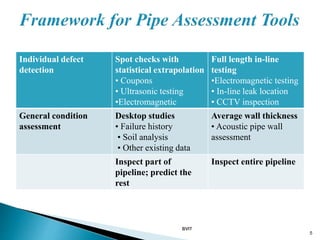

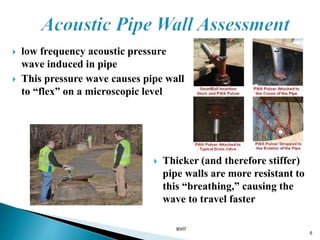

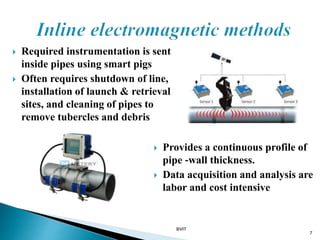

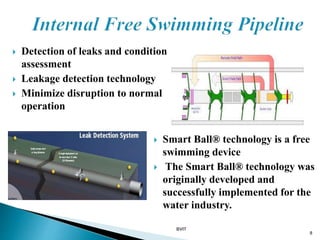

This document discusses piping design and condition assessment. It covers the history of piping technology from Roman wood piping to modern materials like cast iron and PVC. It also outlines common threats to piping like stress, corrosion, and third party damage. The document then describes different methods for inspecting and assessing piping condition, from individual defect detection techniques to full pipeline inspection. These include electromagnetic testing, ultrasonic testing, and internal smart pig inspections. It emphasizes that a well-planned condition assessment program can prioritize repairs, reduce failures, and save money through preventative rehabilitation.