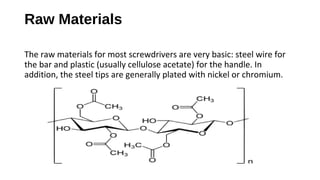

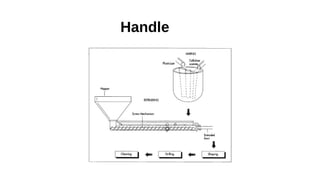

The document describes the process for manufacturing screwdrivers. Steel wire is the raw material, which is drawn to the proper diameter and heat treated to achieve the correct strength. The wire is then cut, formed into the screwdriver shape with the tip and wings, and heat treated again. For professional models, additional tipping and profiling machines further shape the tip. Handles are made by mixing cellulose acetate powder with plasticizers to create a paste, which is extruded and cut into pellets to be molded around the steel bar.