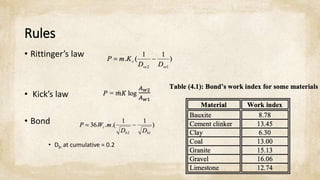

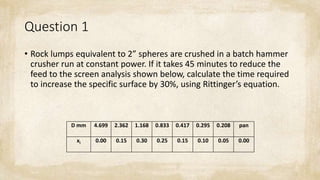

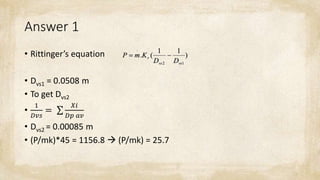

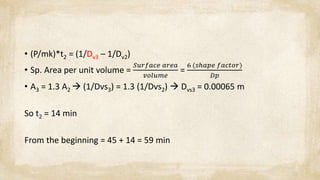

1) Rittinger's law and Bond's law are used to calculate the time required to increase the specific surface area of a rock being crushed by 30%. The calculated time is 59 minutes.

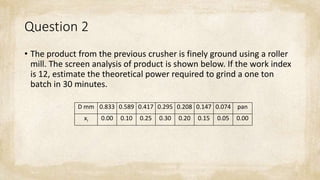

2) Using the given work index, the theoretical power required to grind one ton of a material in a roller mill over 30 minutes is estimated to be 10 horsepower.

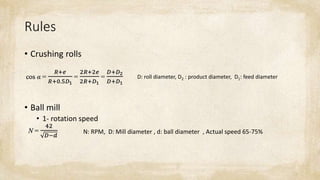

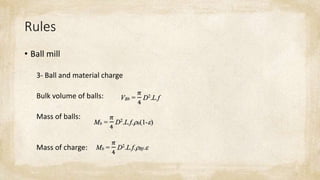

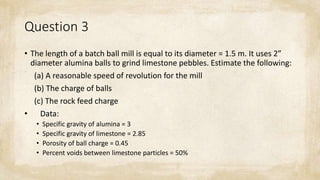

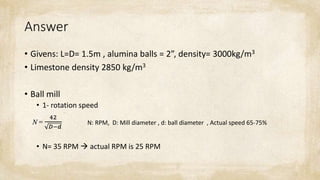

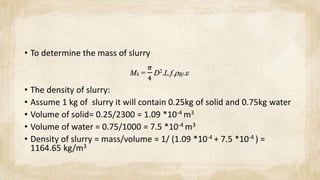

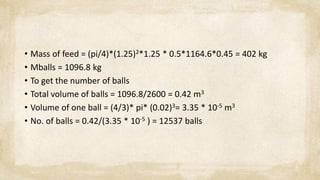

3) For a batch ball mill with given dimensions, specifications of the grinding media, and void ratios: (a) the recommended speed of revolution is 25 RPM, (b) the recommended charge of alumina balls is 1.7 tons, (c) the recommended charge of limestone is 679.9 kg.