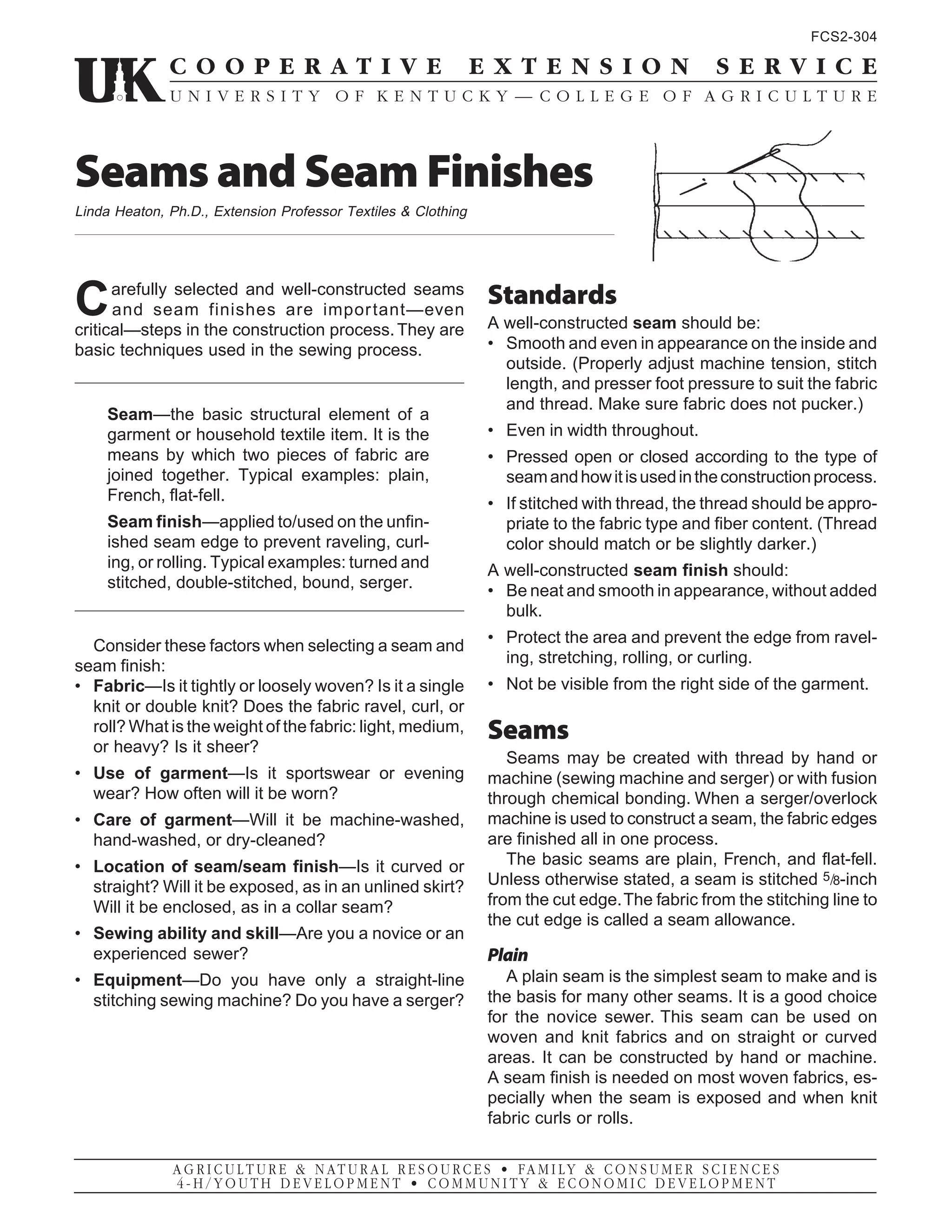

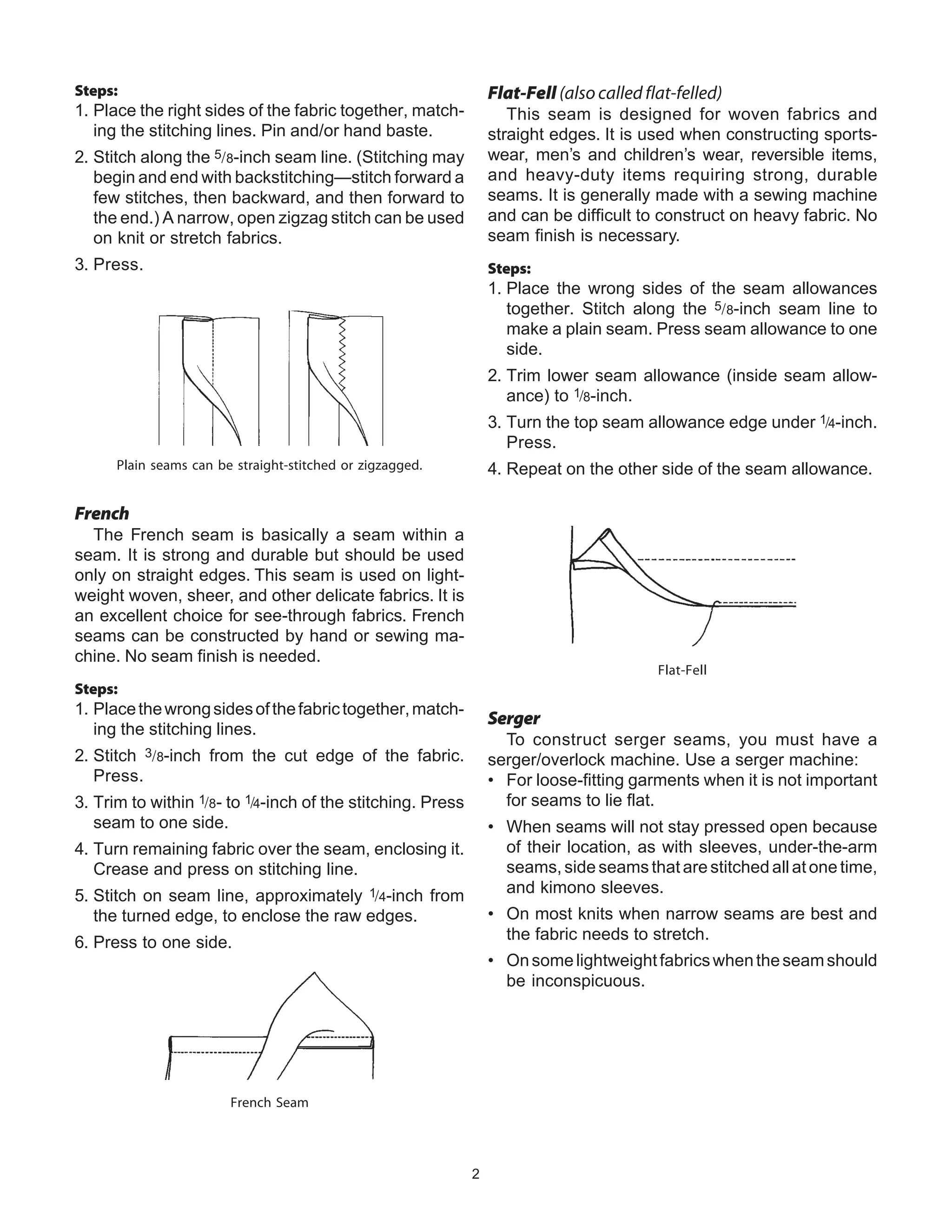

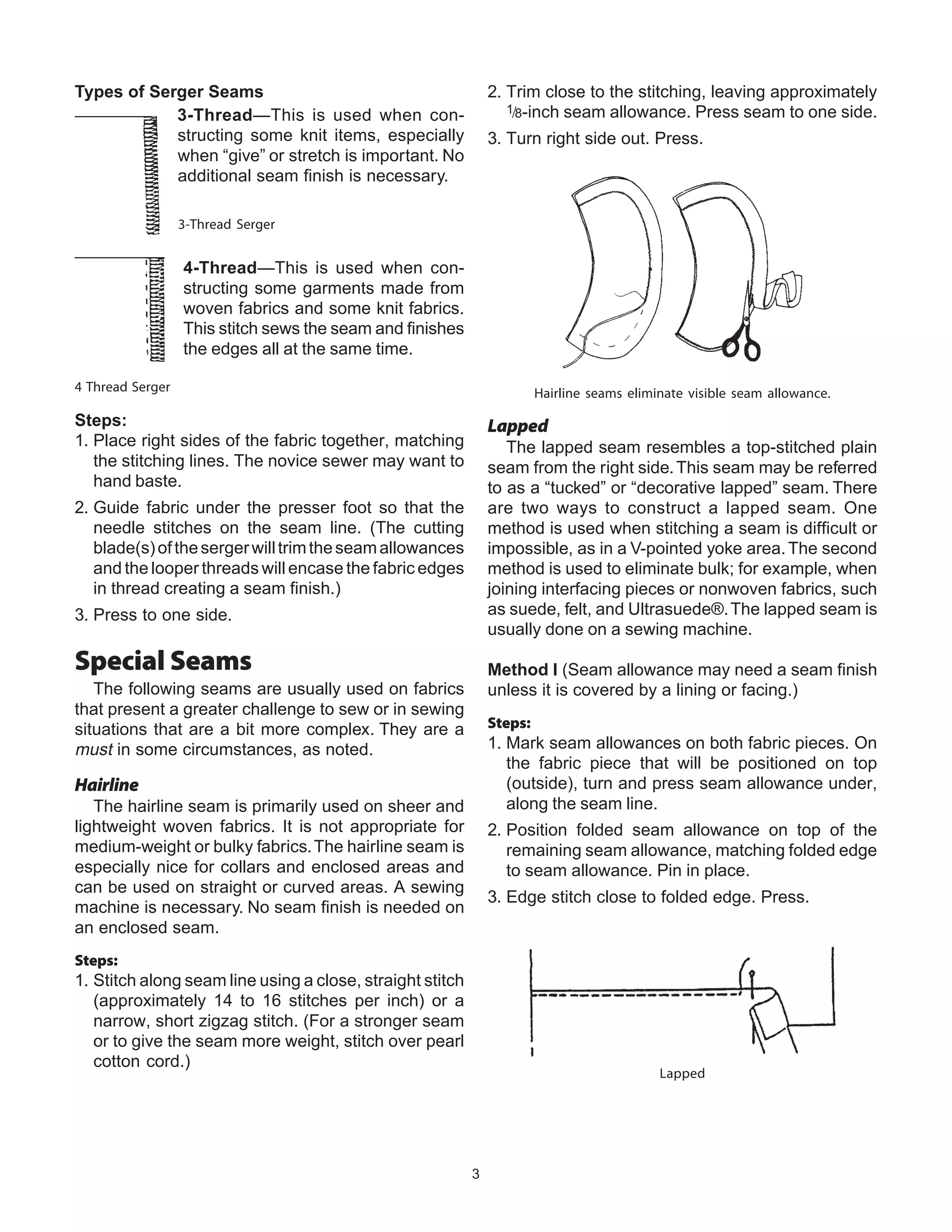

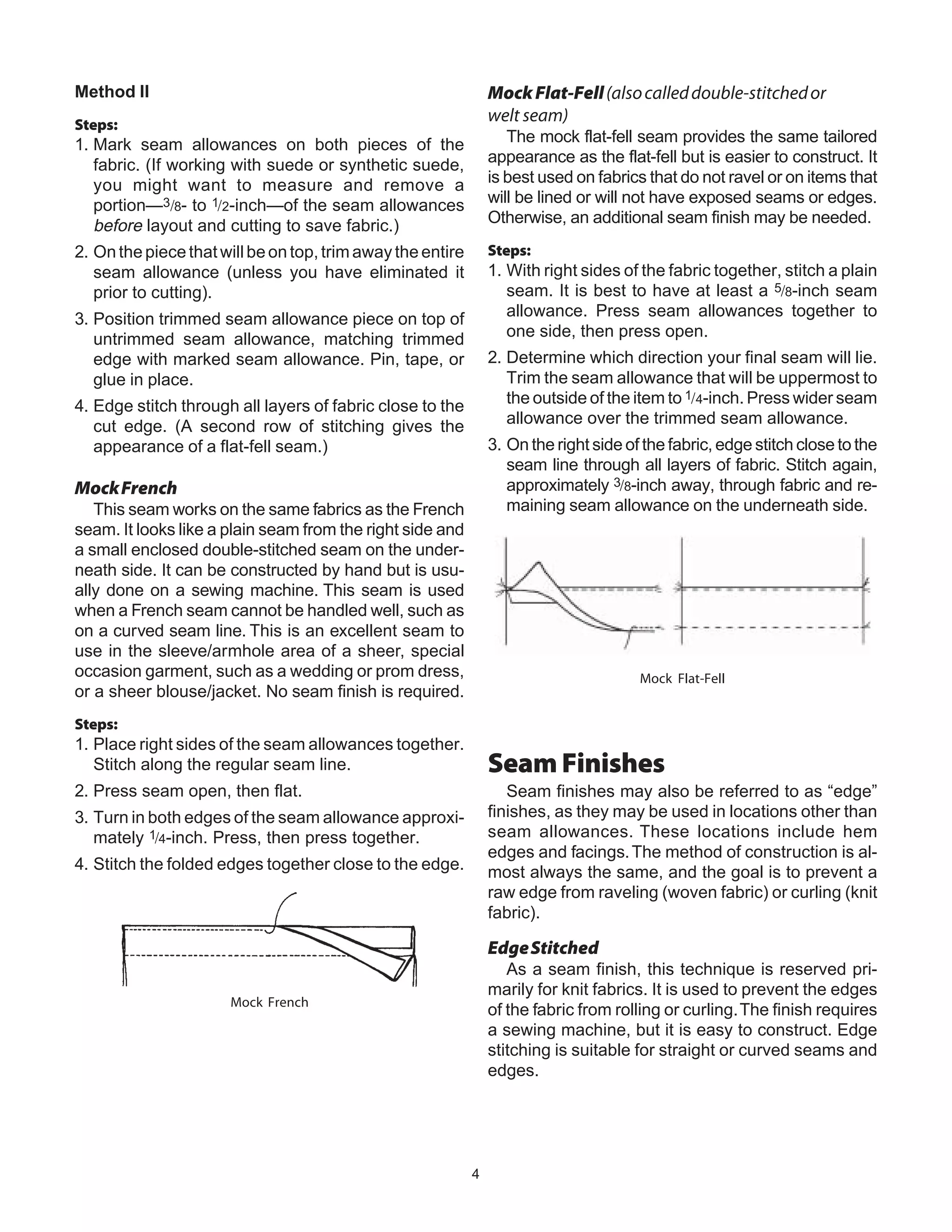

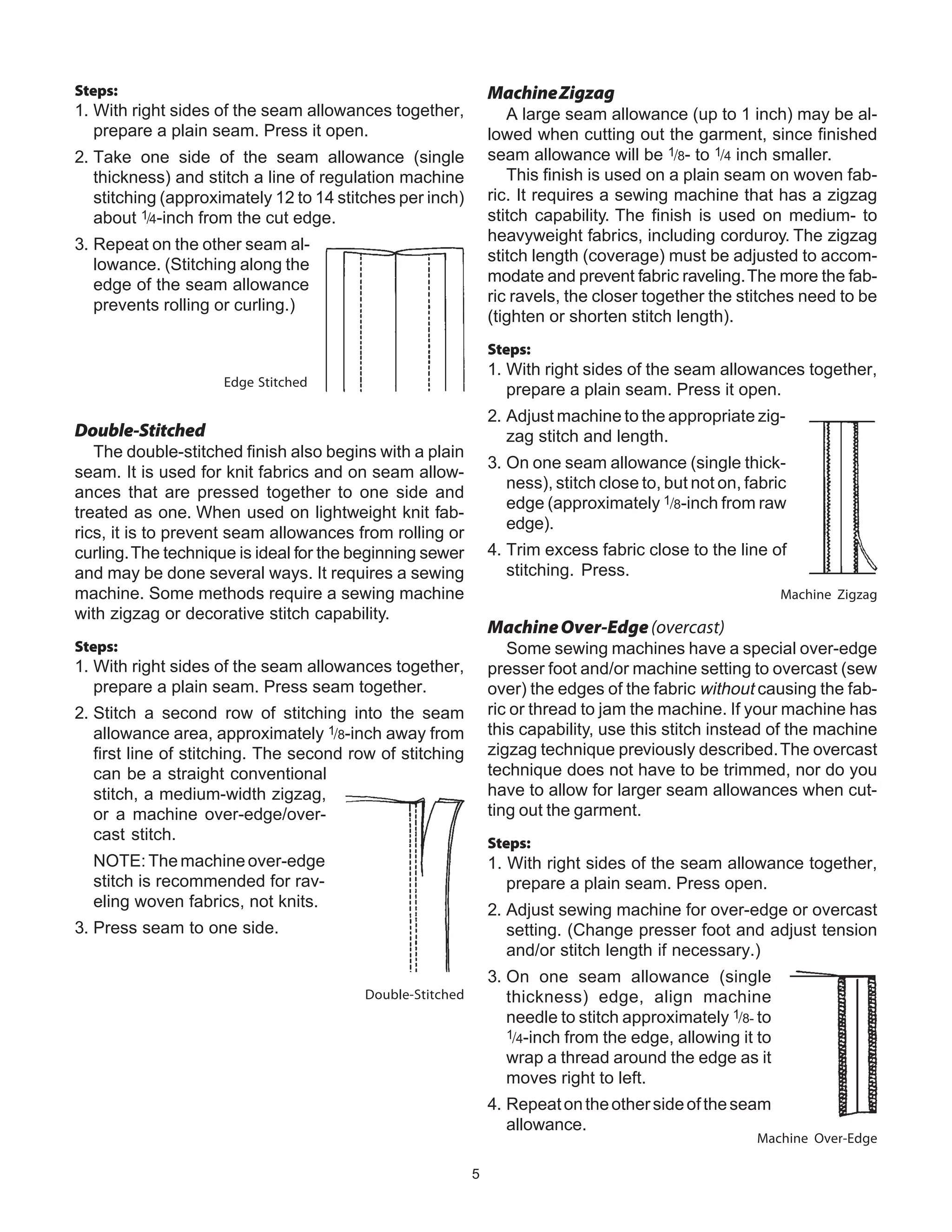

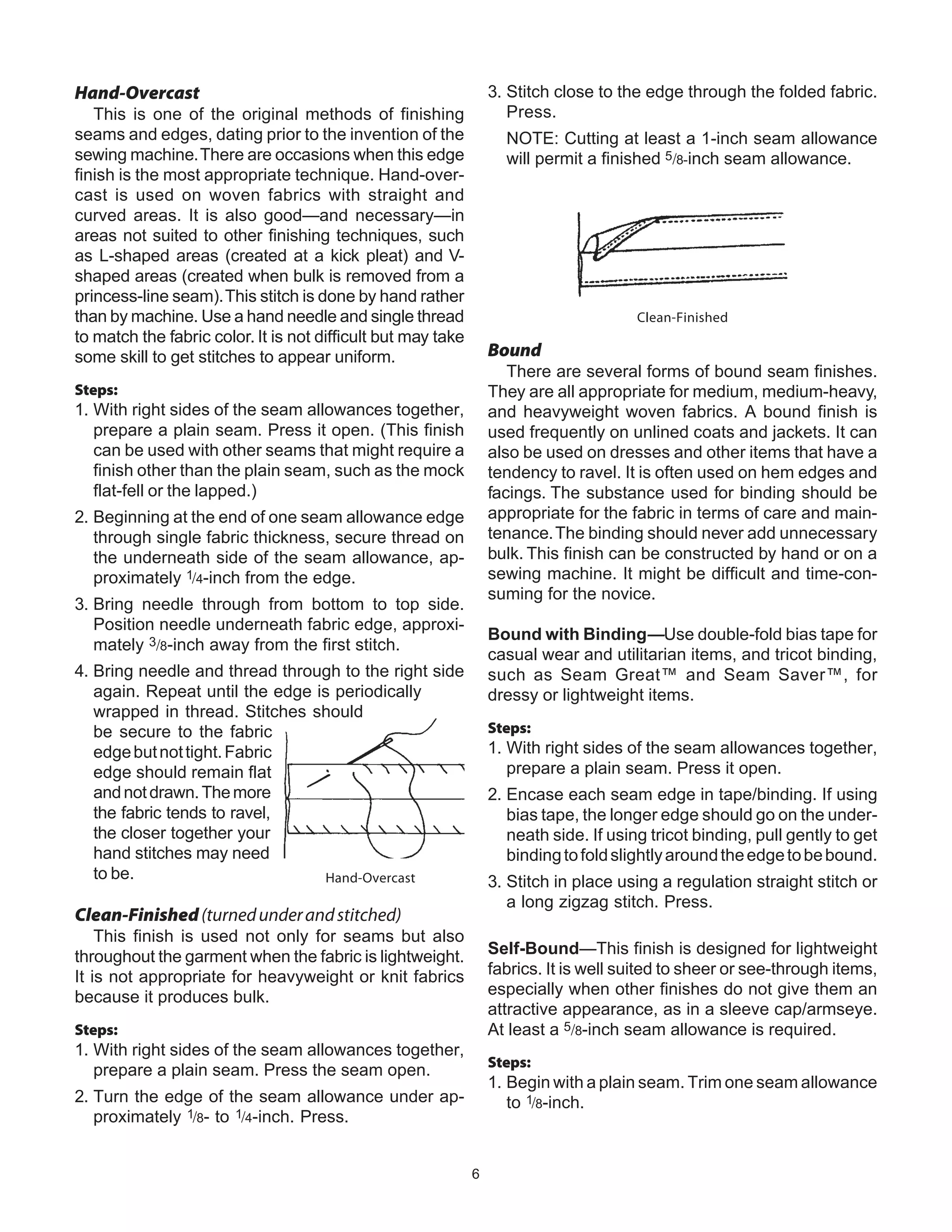

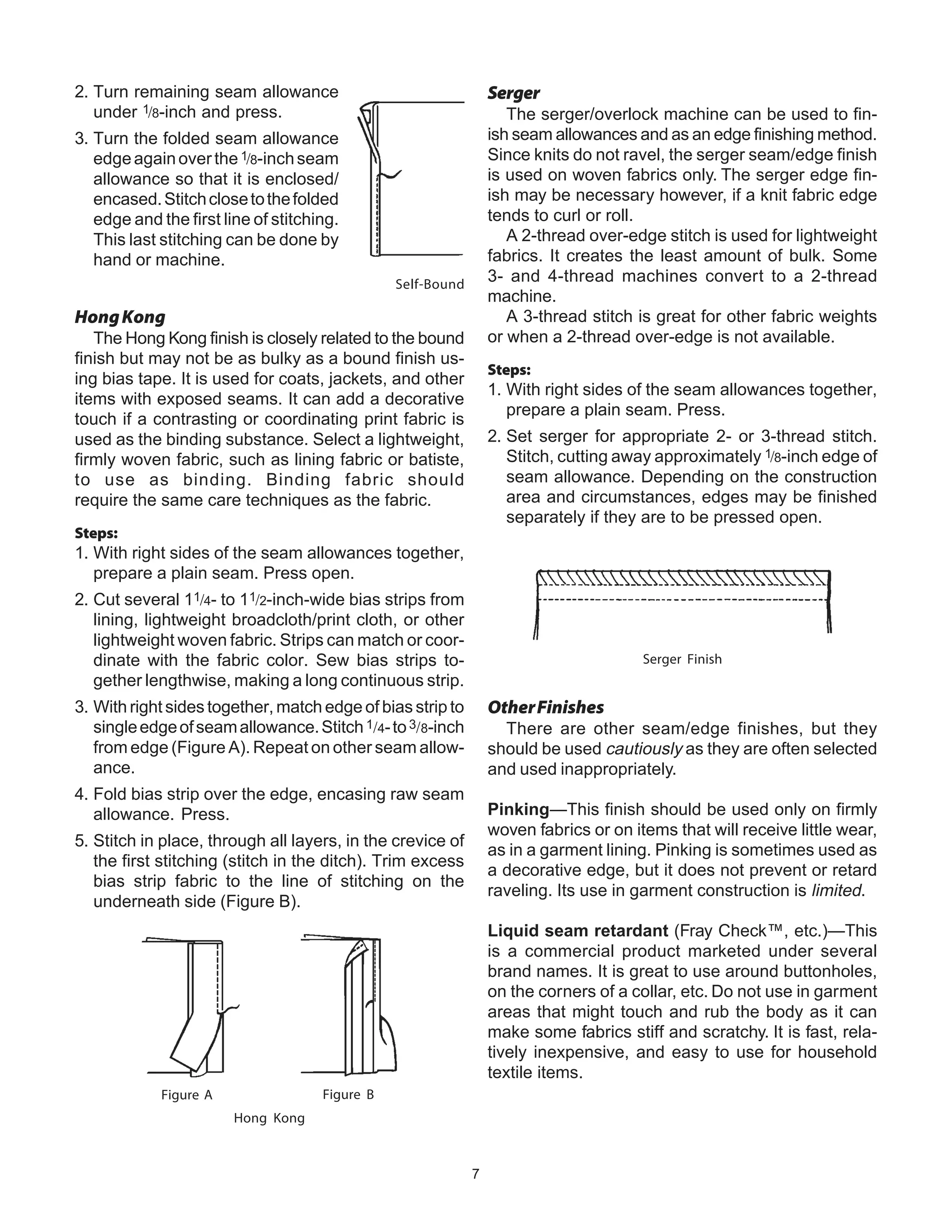

This document provides information on selecting and constructing different types of seams and seam finishes. It discusses factors to consider when selecting a seam, such as the fabric type, intended use, and care of the garment. Common seams like plain, French, and flat-fell are described along with their construction steps. Specialty seams and different types of seam finishes are also outlined, including techniques for woven and knit fabrics. The document emphasizes that seams and finishes should be smooth, even, and protect the fabric edges from raveling or curling.