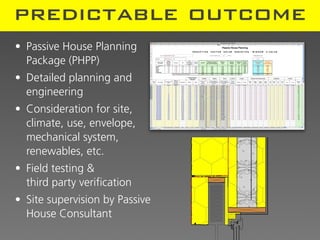

The document details the Passive House design standard, emphasizing energy efficiency, reduced consumption, and comfort through rigorous guidelines and performance requirements. It outlines the history, definitions, and planning considerations necessary to meet certification, including specific energy demand metrics and mechanical systems. The document also highlights the global applicability of the standard while encouraging local adaptation in architectural practices.

![mechanical response

Ihr Vorschlag

Die Anzahl der Pfeile, entspricht

die Anzahl der Flex-Schläuche mit

dem man das Ventil anfahren muss!!

180,00

40

40

20

Obergeschoss

10

60

60

20

10

Erdgeschoss

Alternativ:

40

20 40 10

Planer: Lüfta GmbH * Am Schmiedanger 4 * D-84427 Armstorf

Tel: 08081/9553-0 * Fax: 08081/9553-299 * Mail: info@luefta.de

Ventil- und Luftmengenplan

Planung und Montage

~1 : 100 Bauherr:

Bedieneinheit Standort

Maßstab:

Gewerken abstimmen

Kellergeschoss

Fernschaltung Küche

Deckendurchbrüche

Peak Building Products, LLC

vorbereiten

Projekt:

LM LM : Luftmenge [m³/h] Luftmengenabgleich: 900086 301 White Street SW

Kondensatablauf

haustechnischen

Elektroanschluß

Deckeneinbau: 55388 Watertown, MN

Datum Gez.

Lüftungssystem:

Schlitze und

Zuluft KG EG OG Summe Ventile

Legende: Abluft 29.10.2009 Rap.

Bauvorhaben:

mit allen

ZL 60 60 60 180 8 BV: Konkol

Wandeinbau: Neubau eines Einfamilienhauses

60 90 40 190 8

Wichtig:

Zuluft AL im Niedrighausstandard

Abluft

?

?

?

?

?

?

?](https://image.slidesharecdn.com/2009aiaconventionph-091113002125-phpapp01/85/Passive-House-AIA-MN-Convention-51-320.jpg)