This document discusses spray modeling for lean NOx trap aftertreatment system design. It presents Eaton Corporation's aftertreatment system for reducing NOx and PM emissions. Computational fluid dynamics (CFD) was used to optimize fuel preparation and distribution through injection modeling. Both test-based and CFD-based injection modeling were performed and validated. CFD results showed that smaller droplet sizes and optimized mixer placement improved fuel uniformity and vaporization. CFD modeling aided in comparing injector performances and selecting mixers for the aftertreatment system design.

![3

3SAE INDIA International Mobility Engineering Congress & Exposition, 2009, Chennai

Introduction

Eaton Aftertreatment system

NOx < 0.27 gm/kW-h

PM < 0.02 gm/kW-h

Working

• Lean NOX Trap (LNT) stores the NOX

• During LNT regeneration, Reformer produces H2

and CO, which are used to purge the LNT

• LNT releases the NOX as Nitrogen and NH3

• Selective Catalytic Reduction (SCR) uses the

released NH3 and treats the slipped NOX

• Diesel Particulate Filter (DPF) traps the Particulate

Matter (PM)

Product Differentiator

• Single fluid system [Dosing System needed]

• Independent of urea infrastructure

• Flexible, customized and smaller packaging

• Scalable with engine power (size)

# Ref: Hu, DEER Conf 2006, McCarthy, SAE2009-01-2835

Emission Regulation for Highway Vehicle#

Eaton Aftertreatment System#](https://image.slidesharecdn.com/efe69fc2-8b46-46ab-a4a9-9ec7e54f8c04-160106194401/85/SAE_CONF_v1-7-3-320.jpg)

![5

5SAE INDIA International Mobility Engineering Congress & Exposition, 2009, Chennai

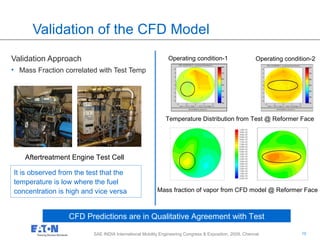

EAS modeling Approach…

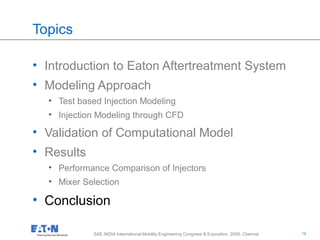

Role of CFD

• Optimize fuel preparation path

• 100% fuel vaporization

• Uniform flow and fuel distribution

Challenges

• Fuel injection modeling

Computational Domain

Exh Flow In

InjectorMixer-1Mixer-2Reformer

Boundary Condition

• Inlet – Transient Profile

• Reformer - Porous media

• Mixers: Zero Thickness wall

• Walls: Convective in steady

environment

Fuel Droplet Tracking

• Lagrangian method [DPM]

Exh Flow Out

Inlet: Transient Profile Boundary Condition

0

5

10

15

20

25

30

0 5 10 15 20 25 30

Time [sec]

ExhMassFlux[kg/m^2-s]

0

100

200

300

400

500

600

Fueling[gpm];Temperature[K]

B25 Exhaust Mass Flux (kg/m^2-2) B25 Exhaust Temperature (K)

B25 Exhaust O2 Concentration (%) B25 Fuel Mass Flow (grams/min)

0

2

4

6

8

10

O2Concentration[%]](https://image.slidesharecdn.com/efe69fc2-8b46-46ab-a4a9-9ec7e54f8c04-160106194401/85/SAE_CONF_v1-7-5-320.jpg)

![7

7SAE INDIA International Mobility Engineering Congress & Exposition, 2009, Chennai

Axis

Spool wall

Wall

SwirlChamber Point of

Injection

Axis

Direction Vector

• Axial

• Swirl

Axis

Spool wall

Wall

SwirlChamber Point of

Injection

Axis

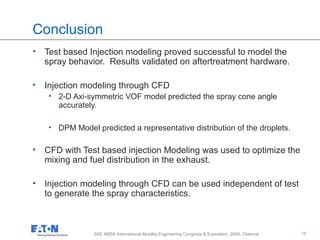

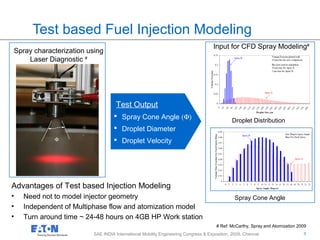

Injection Modeling through CFD

Step -1 : Geometry Details

Multiphase Flow Simulation

(Volume of Fluids -- VOF)

Step-2: Droplet Modeling [DPM]

Pressure Swirl Atomizer (Break up

& Coalescence)

• Droplet Distribution

• Droplet Diameter

• Spray Cone Angle

• Pressure Drop

2- D Axisymmetric VOF Domain 2- D Axisymmetric DPM Domain

Injector Geometry

Step-1 - VOF Step-2

Computational Domain

for Droplet Modeling](https://image.slidesharecdn.com/efe69fc2-8b46-46ab-a4a9-9ec7e54f8c04-160106194401/85/SAE_CONF_v1-7-7-320.jpg)

![12

12SAE INDIA International Mobility Engineering Congress & Exposition, 2009, Chennai

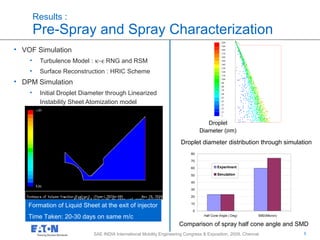

Results :

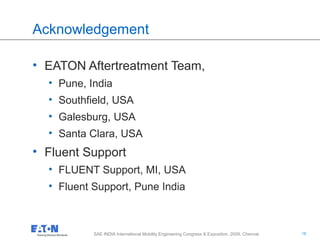

Performance Comparison of Injectors

Comparison of wall wetting and Mass Fraction contour

Exhaust System with Spray A

Exhaust System with Spray B

Smaller droplets : Higher fuel uniformity and Better vaporization

• Spray A [ Large Droplets ]

• Fuel uniformity is low

• Higher wall wetting

• Spray B [ Small Droplets]

• Higher fuel uniformity

• Low wall wetting

Diameter distribution of droplets

Spray B

Spray A

High

Low](https://image.slidesharecdn.com/efe69fc2-8b46-46ab-a4a9-9ec7e54f8c04-160106194401/85/SAE_CONF_v1-7-12-320.jpg)