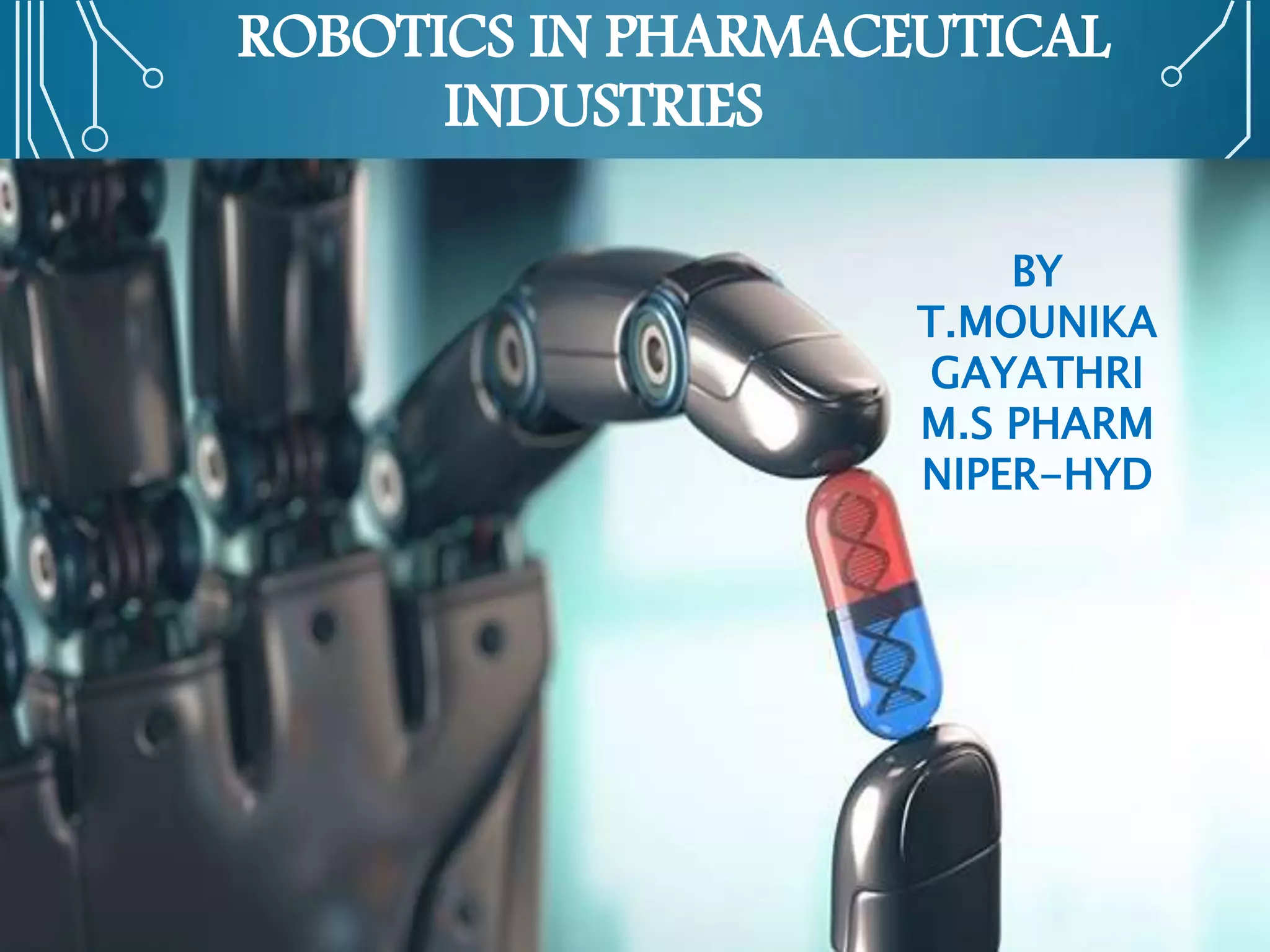

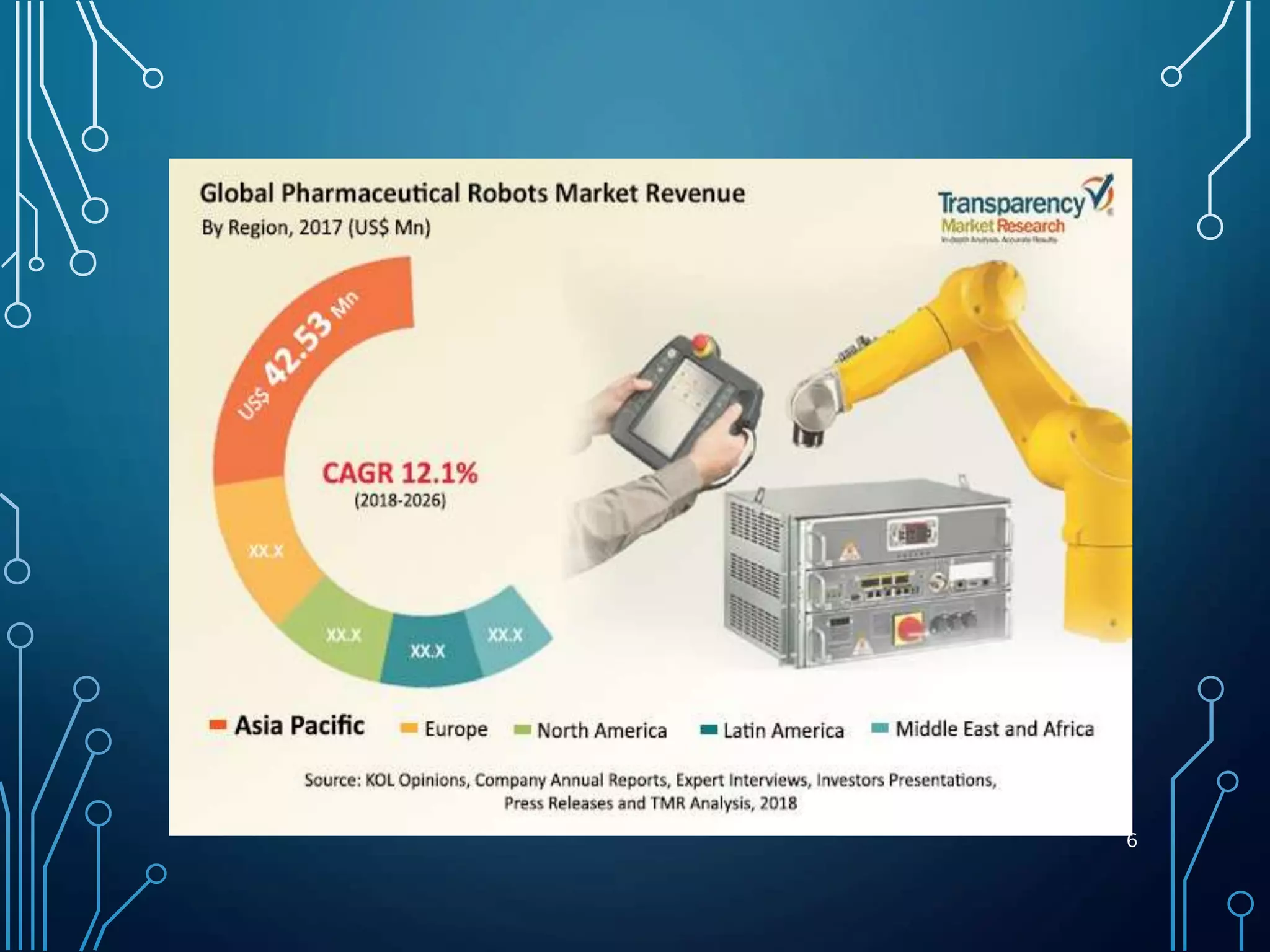

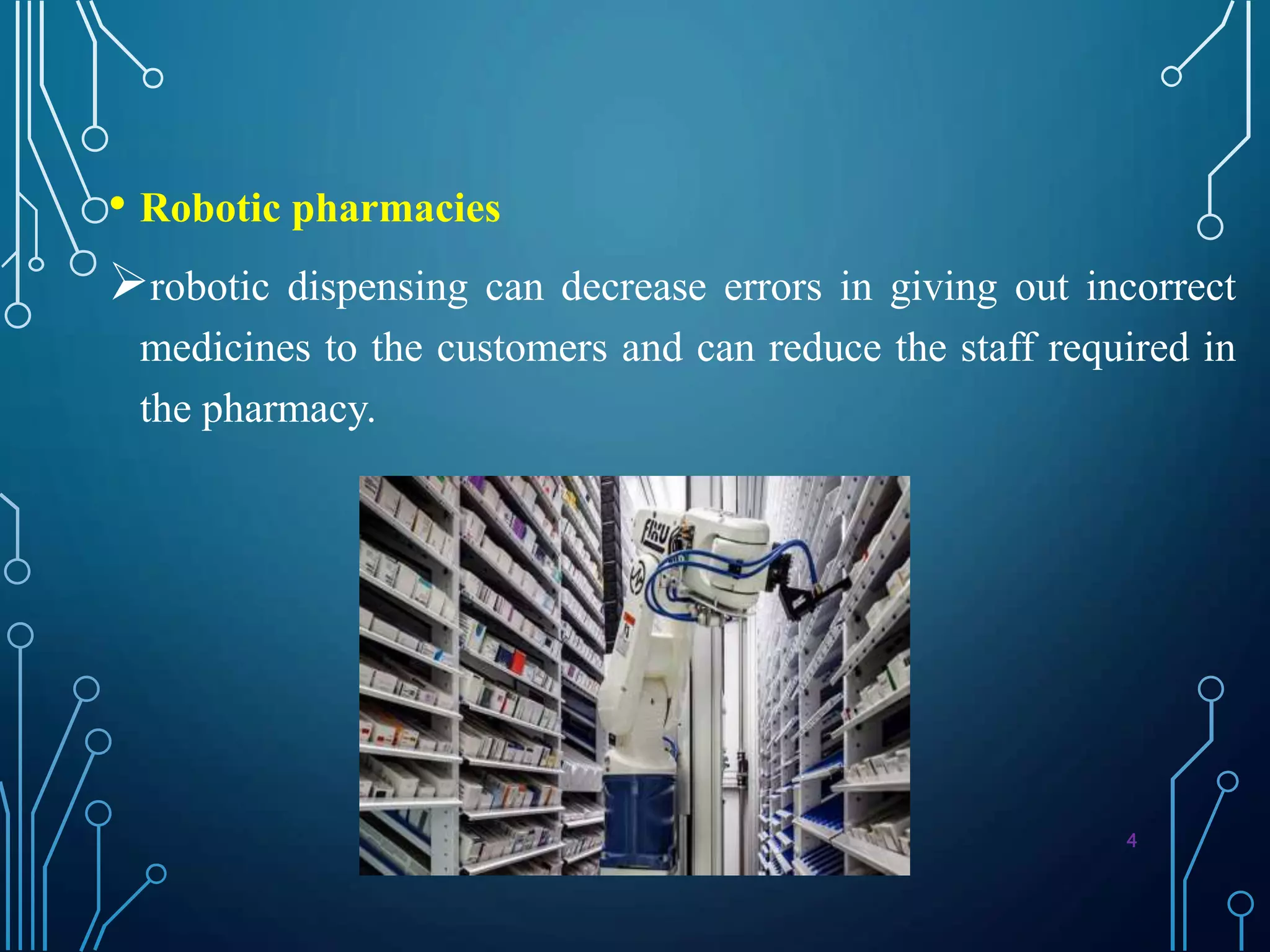

The document discusses the use of robotics in the pharmaceutical industry, highlighting their role in boosting productivity and ensuring precision in various processes such as drug development and manufacturing. It outlines the types of robots utilized, the benefits they provide including accuracy and operational efficiency, and the challenges posed by their implementation, such as high costs and the need for specialized training. Ultimately, it concludes that robots offer significant potential for enhancing efficiency, safety, and quality in pharmaceutical operations.