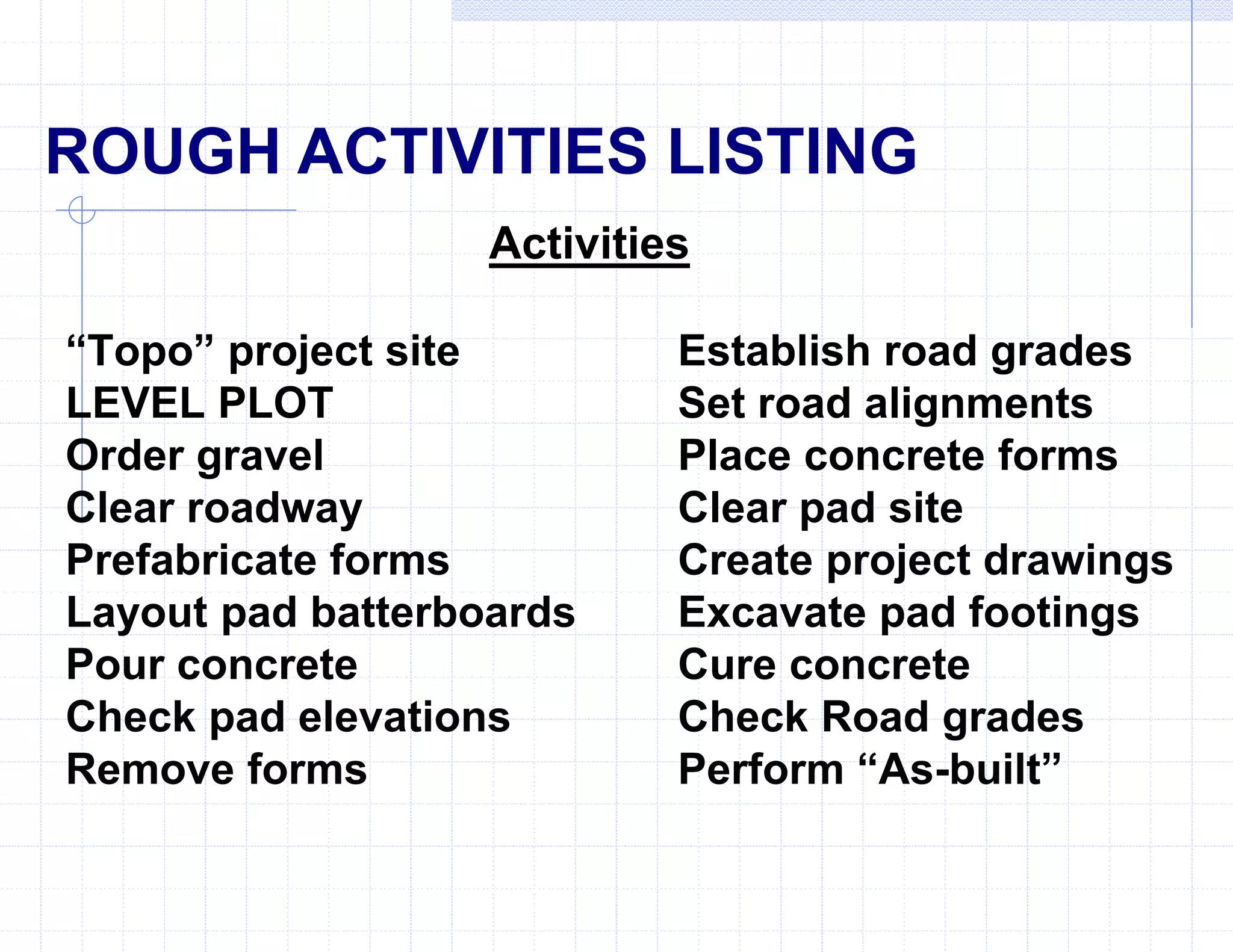

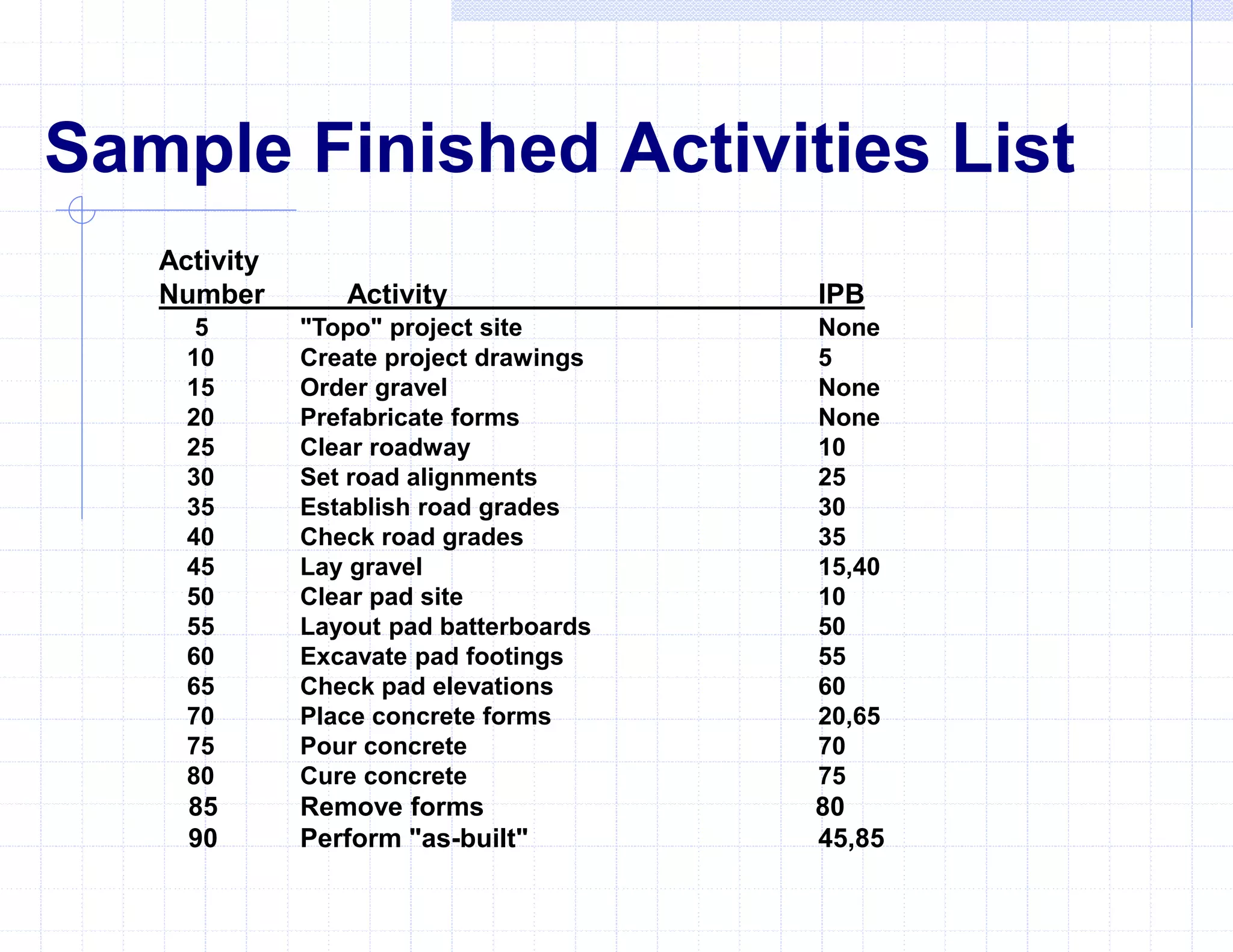

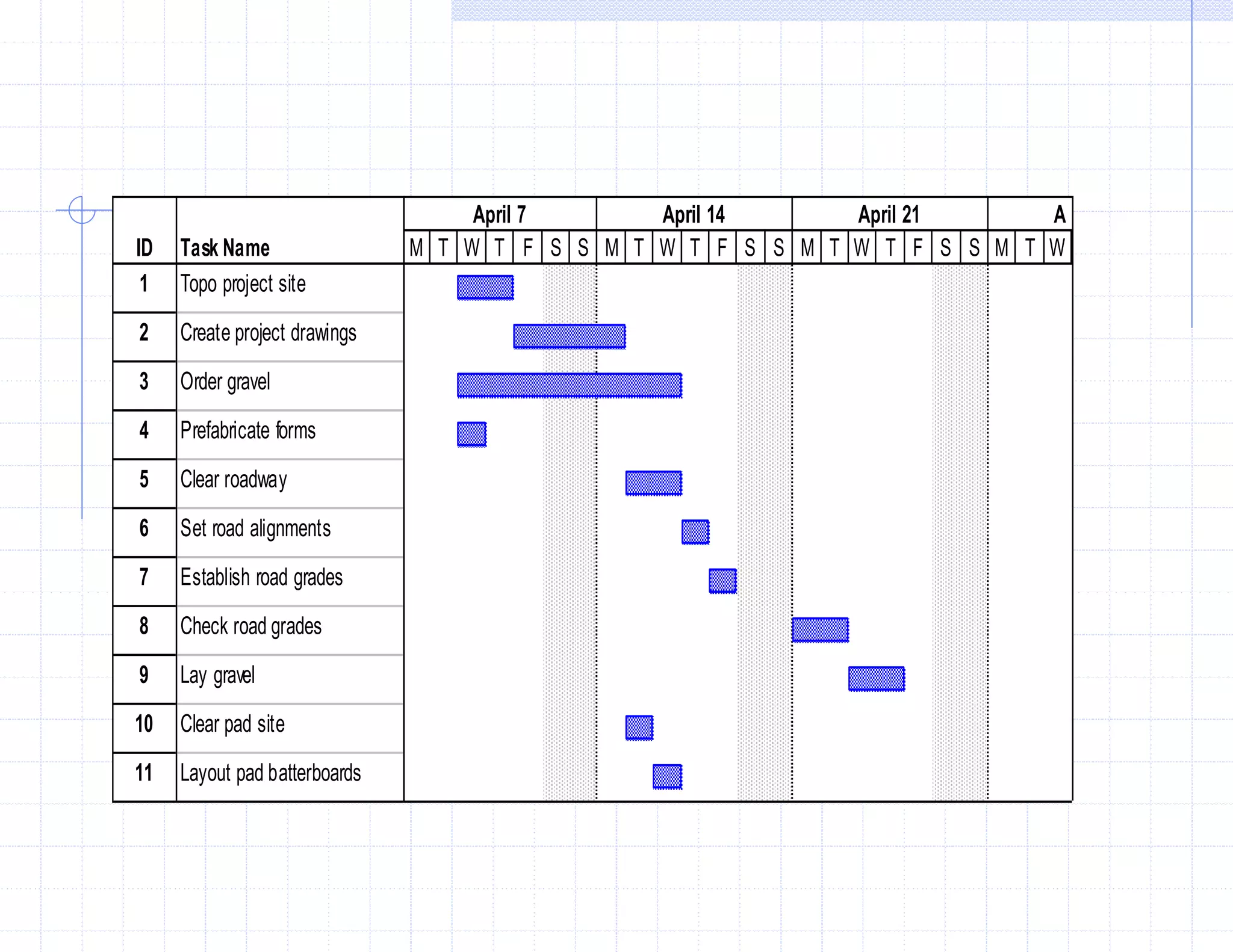

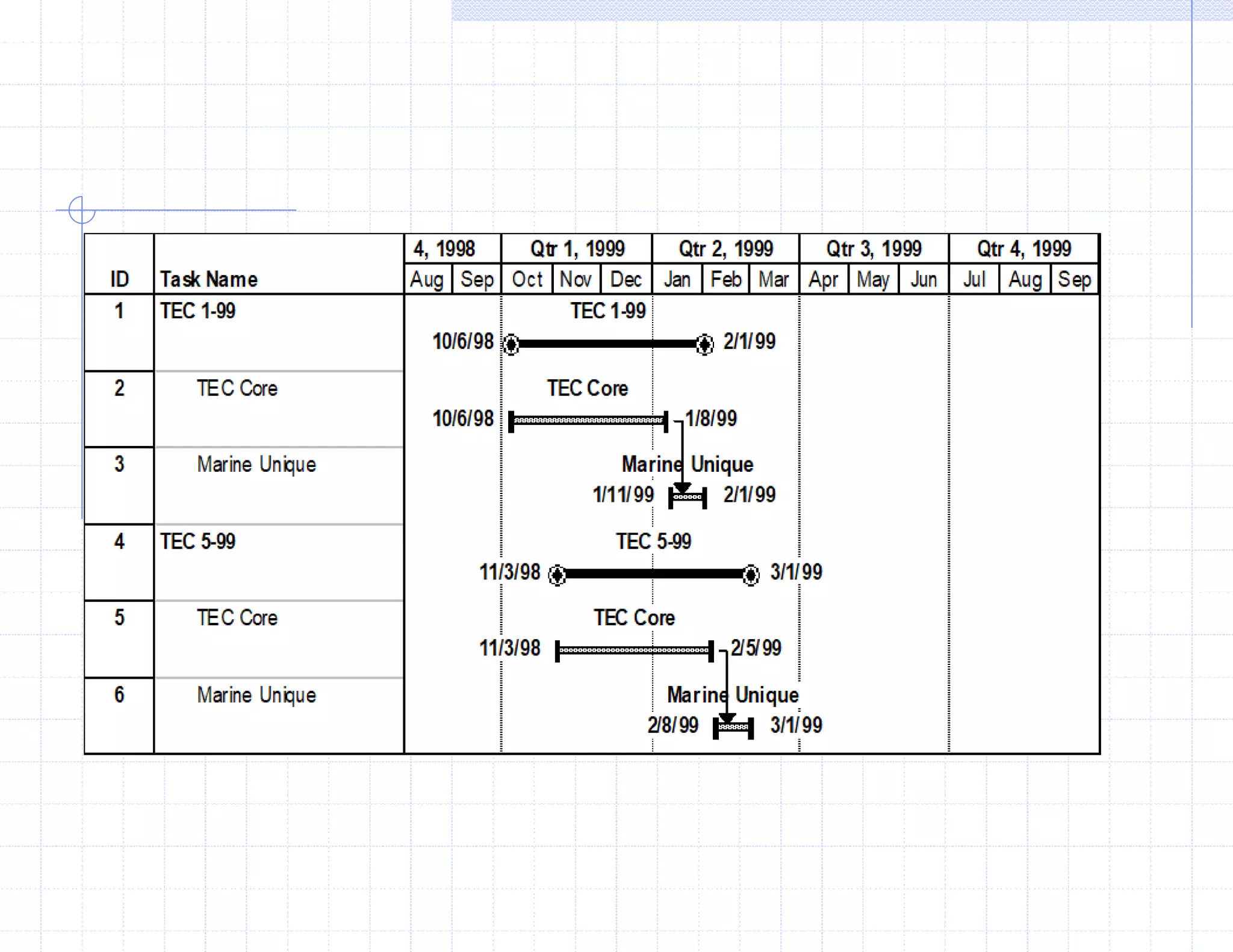

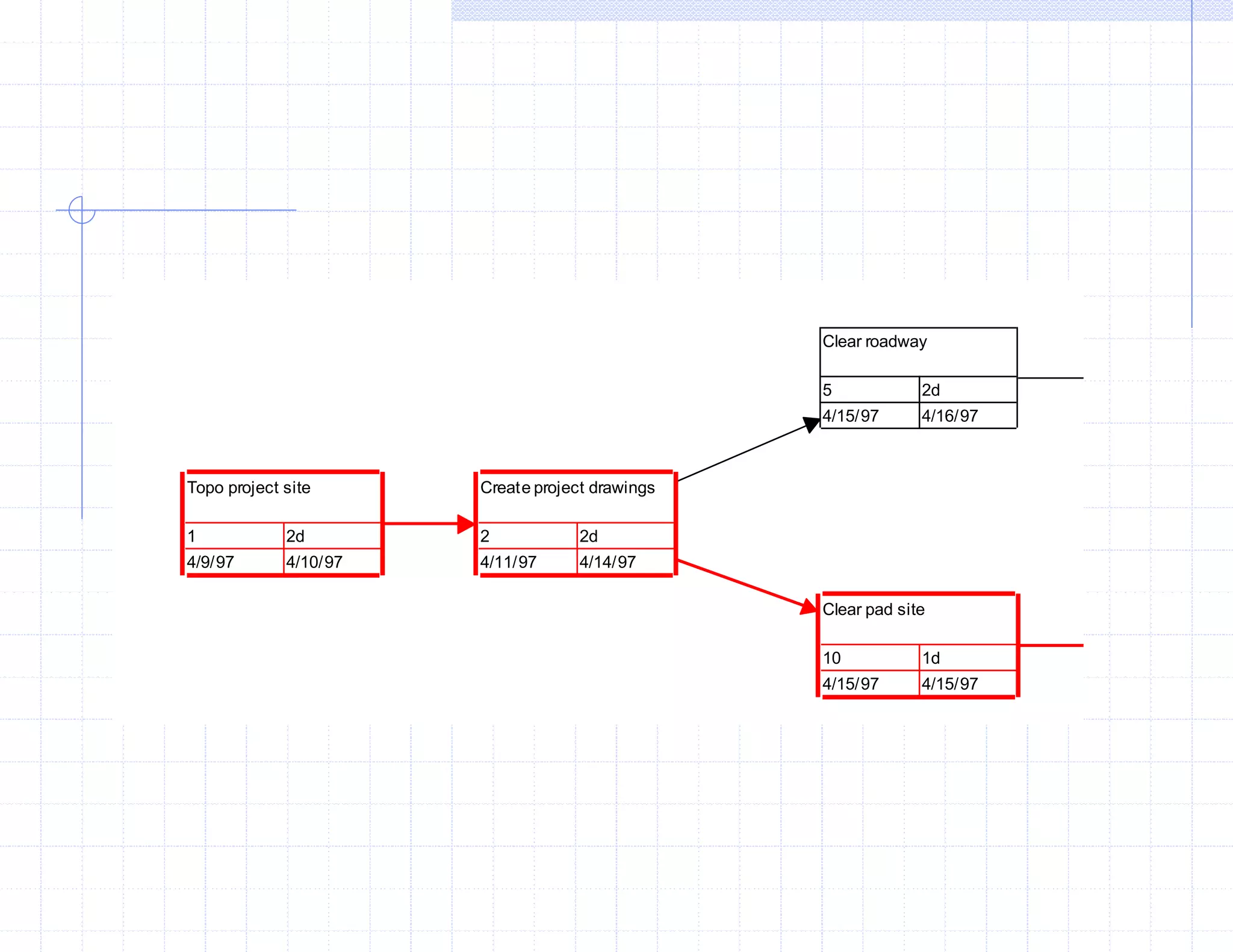

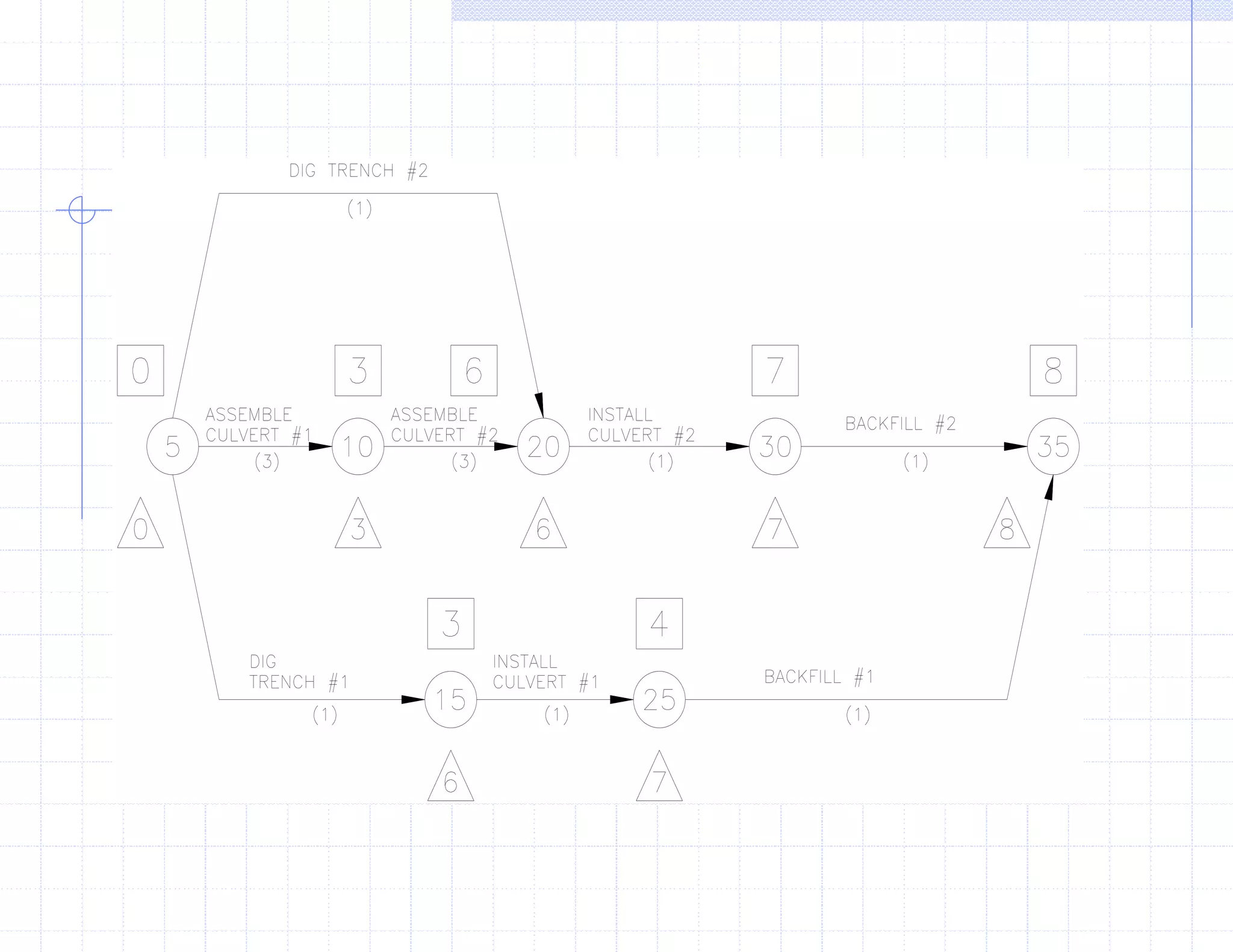

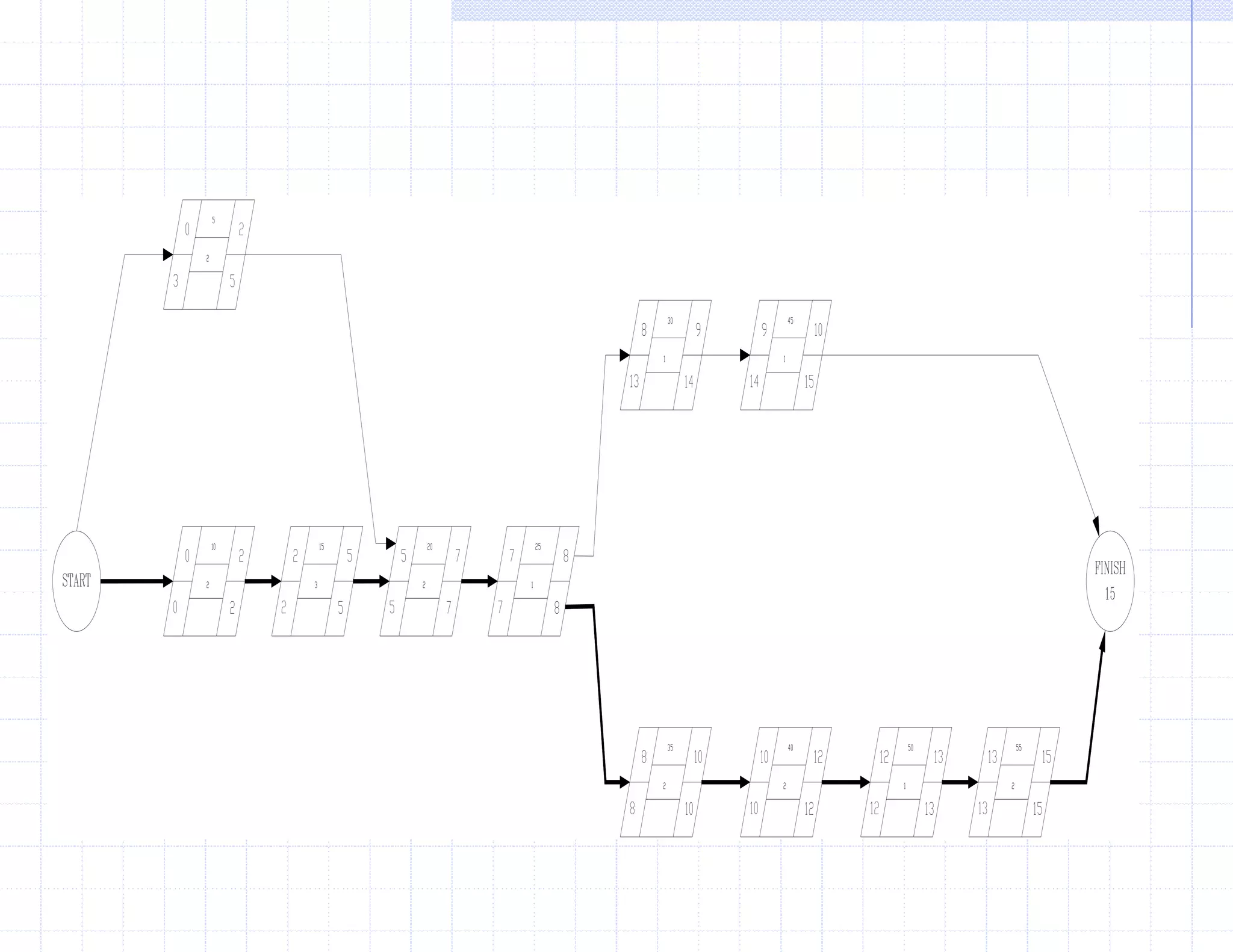

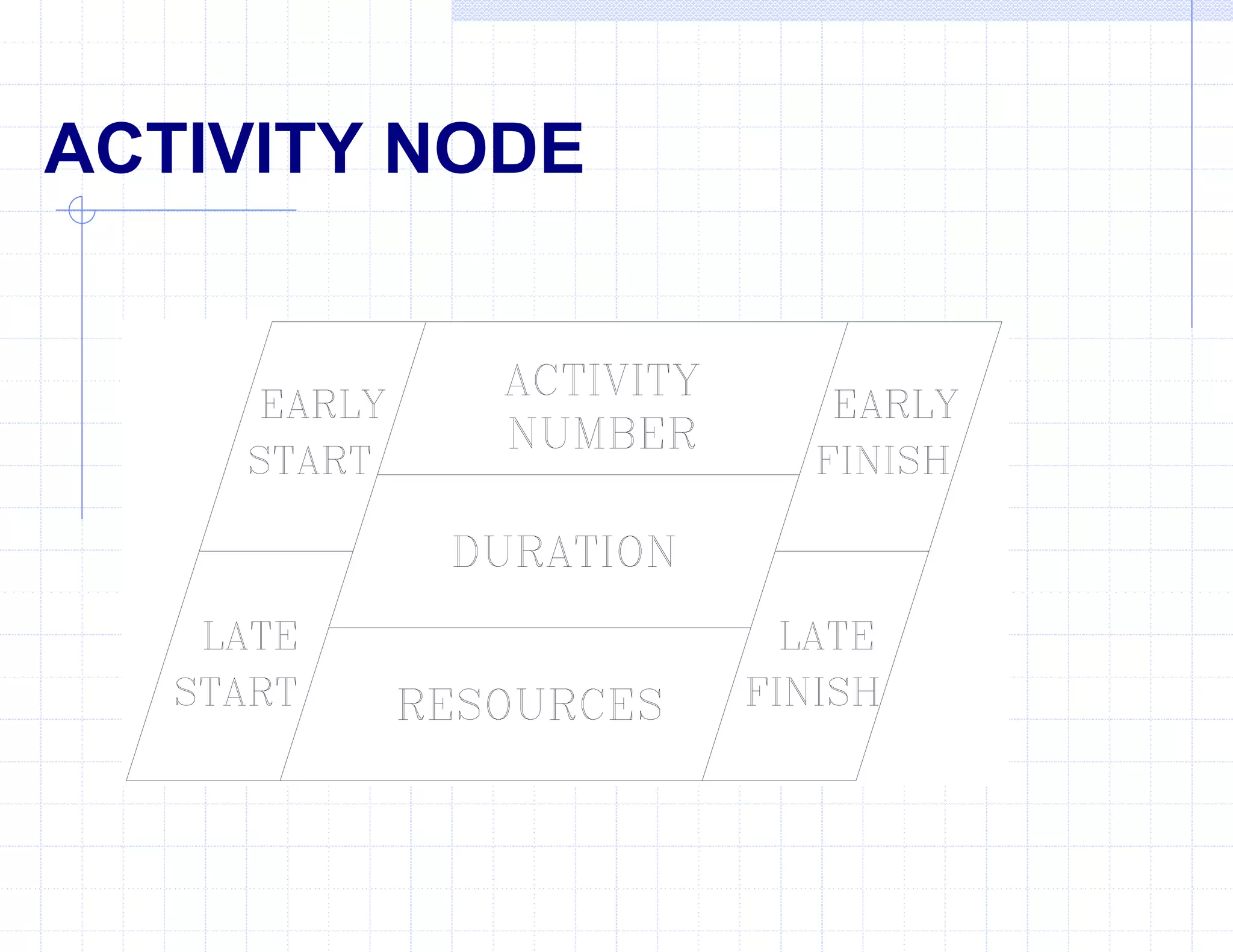

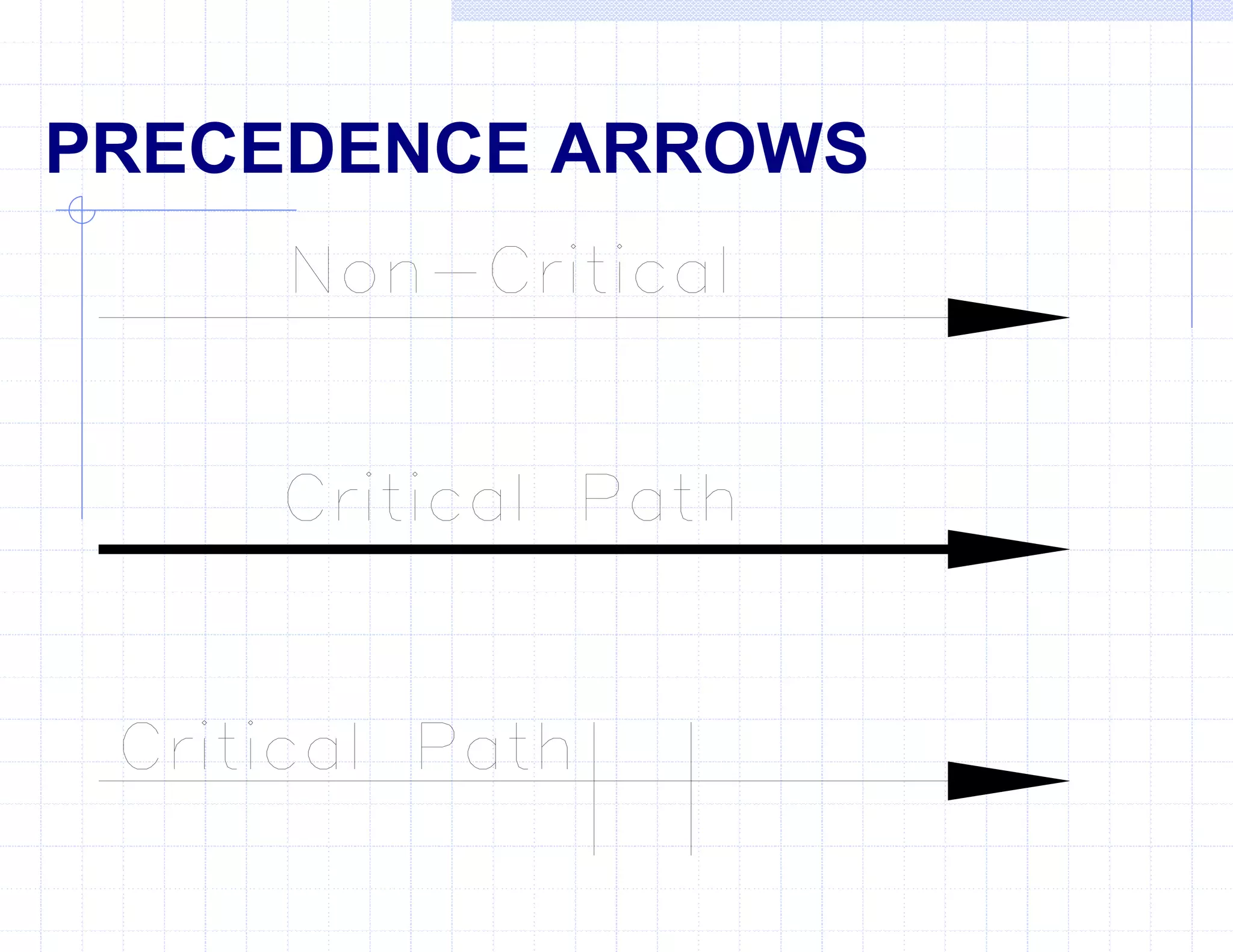

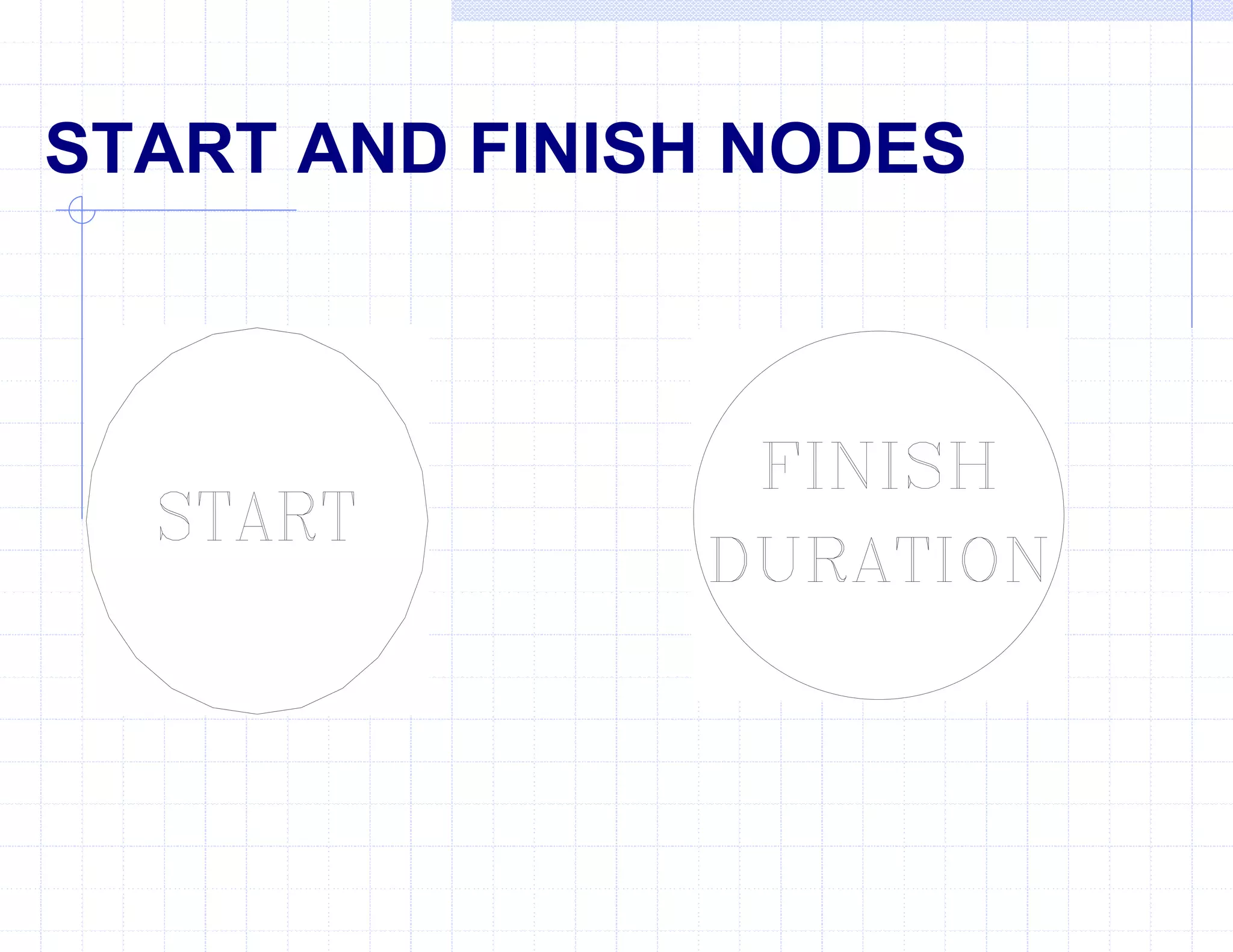

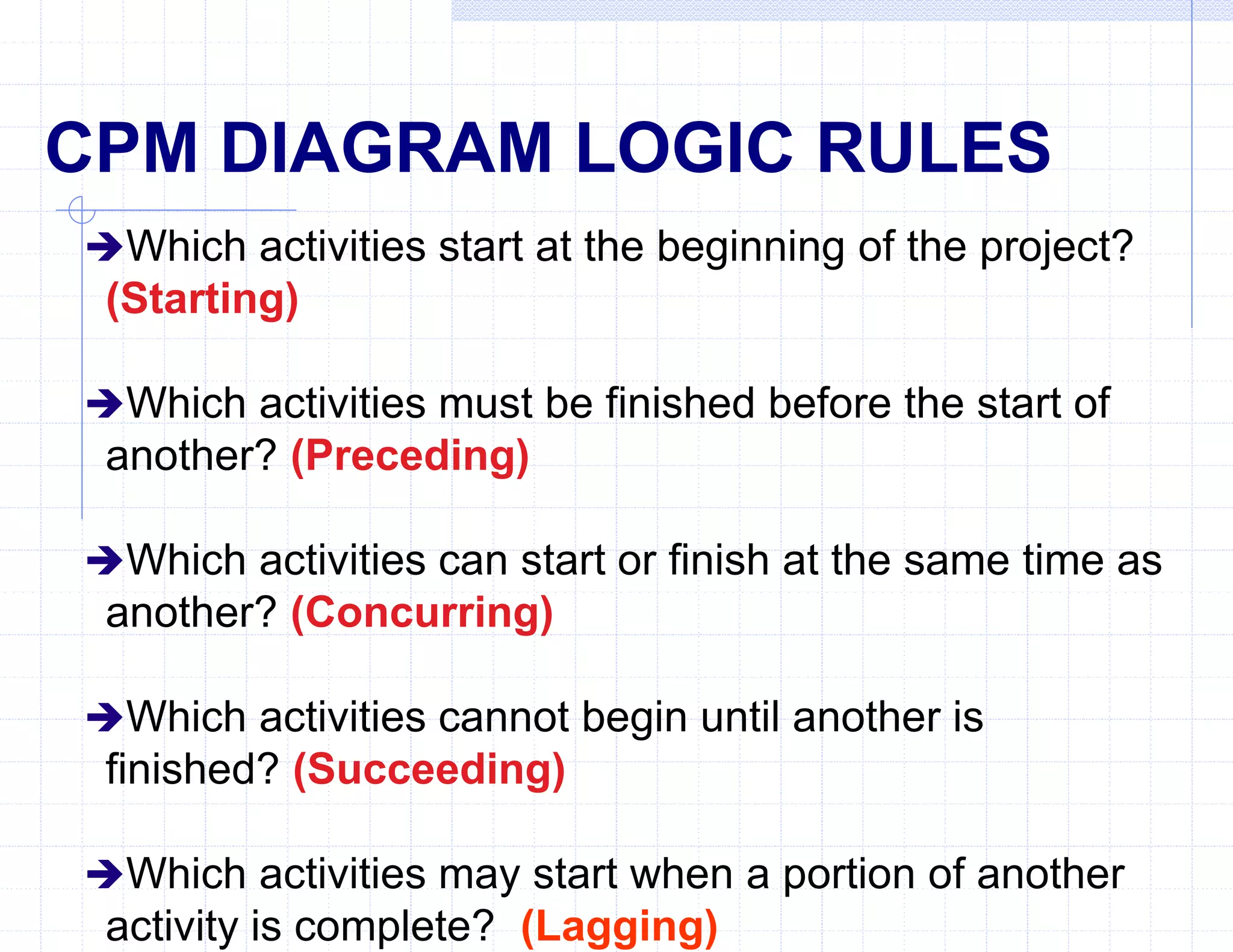

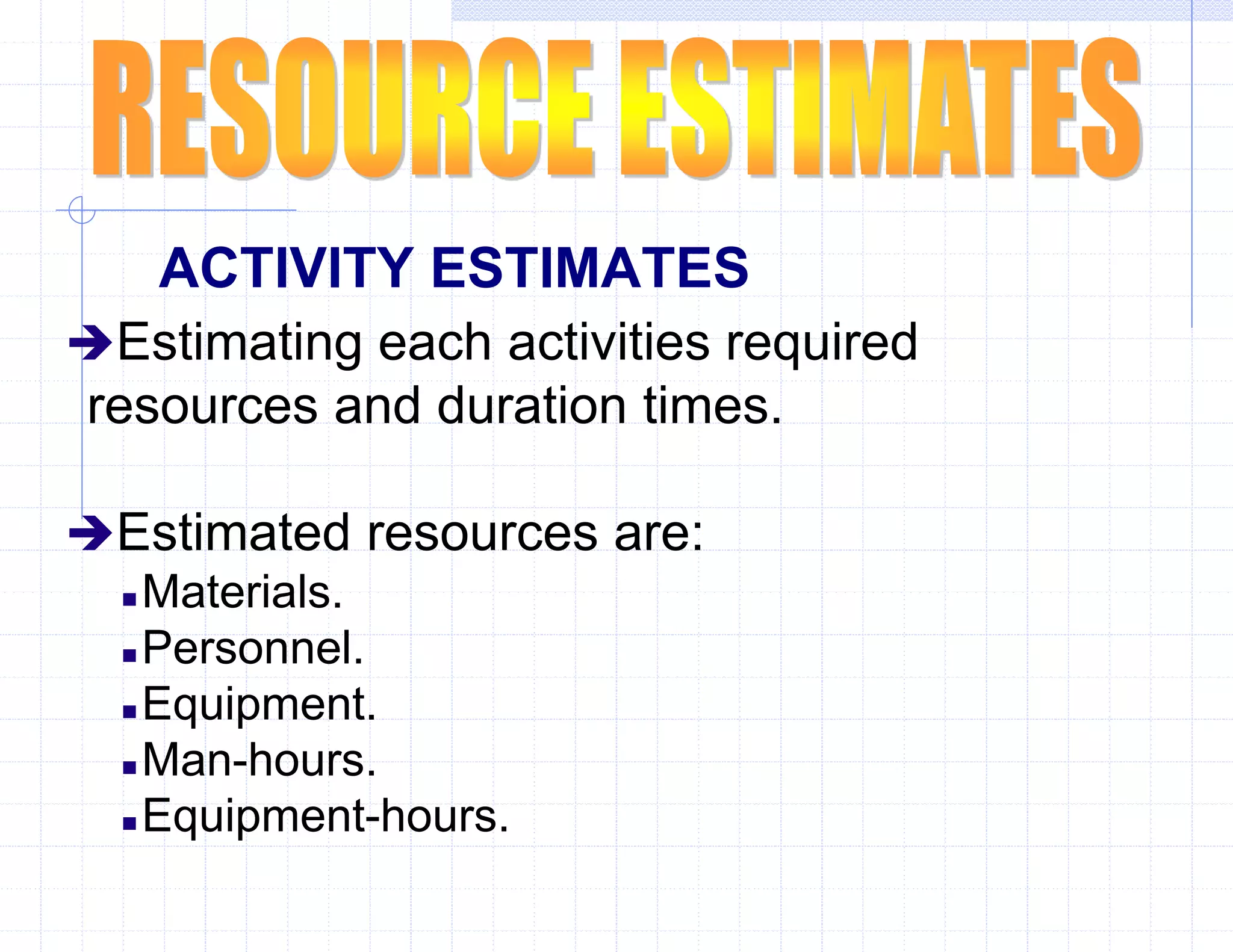

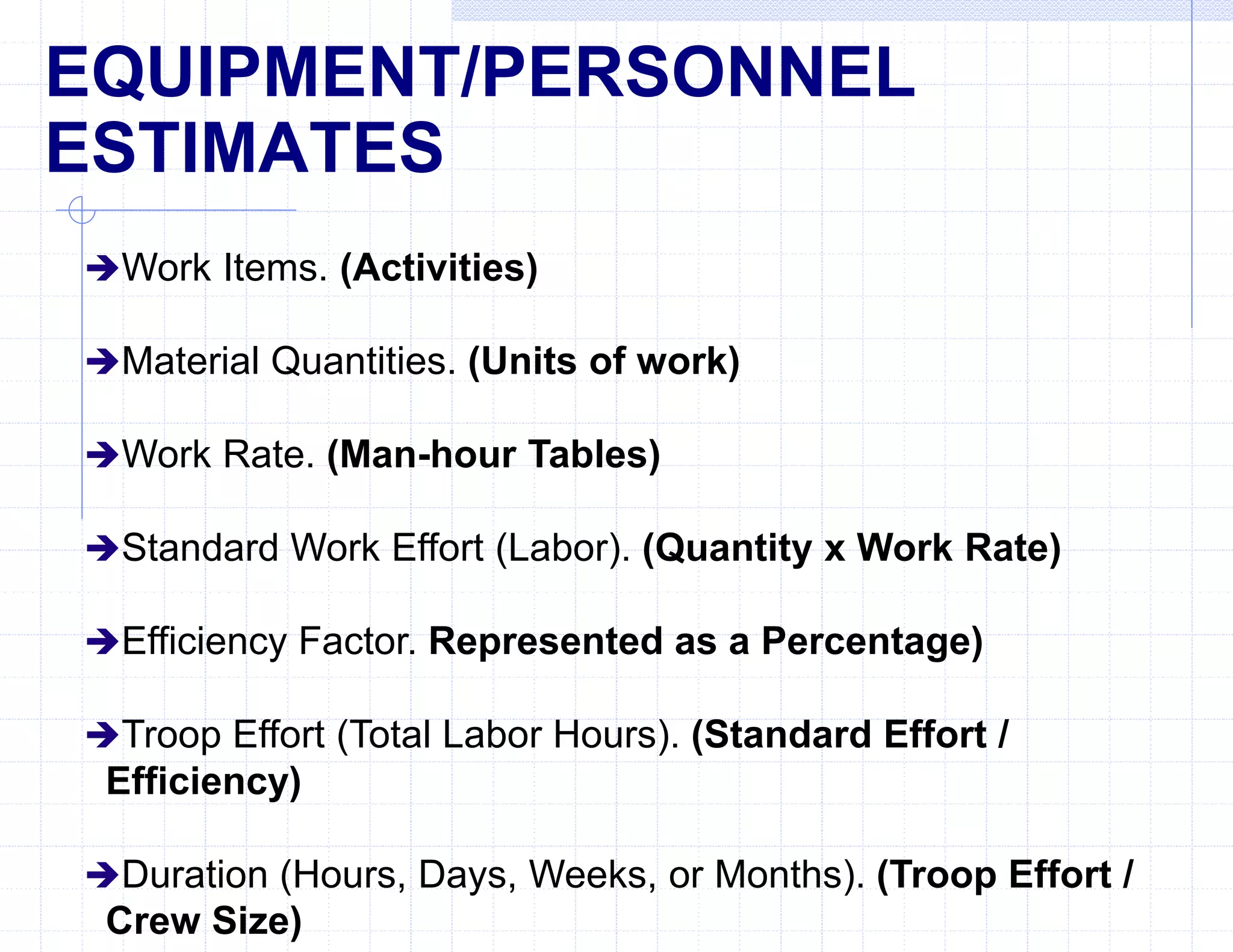

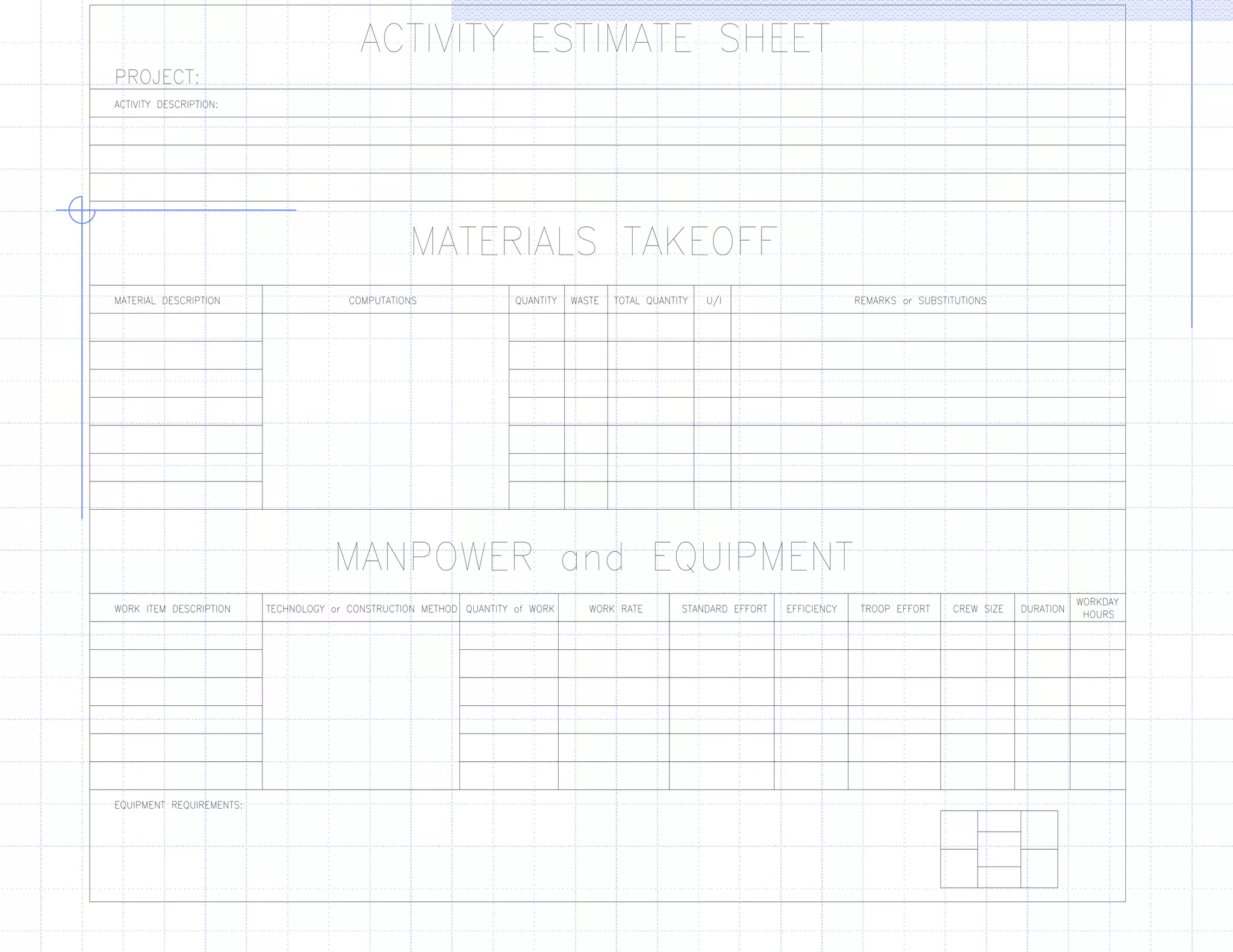

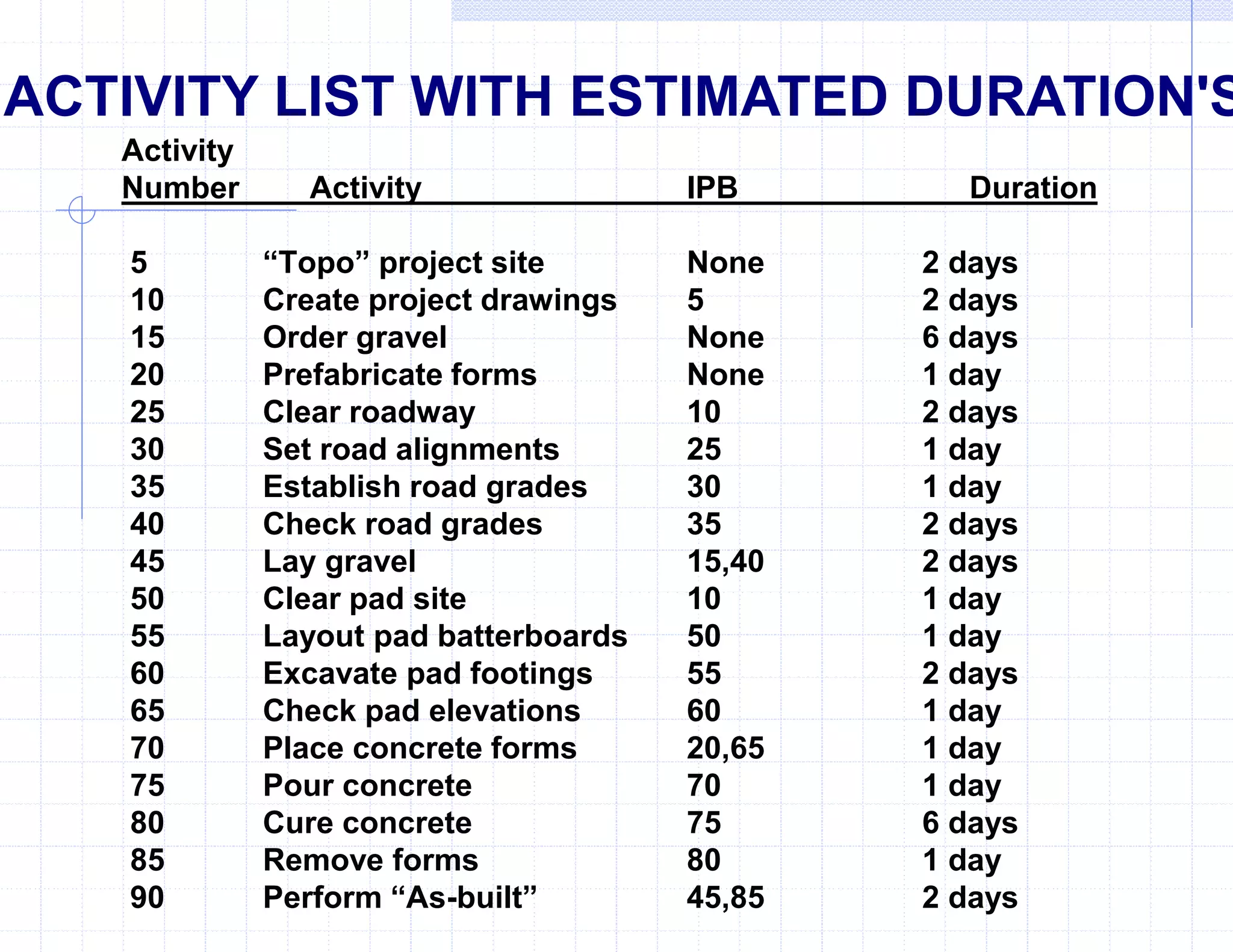

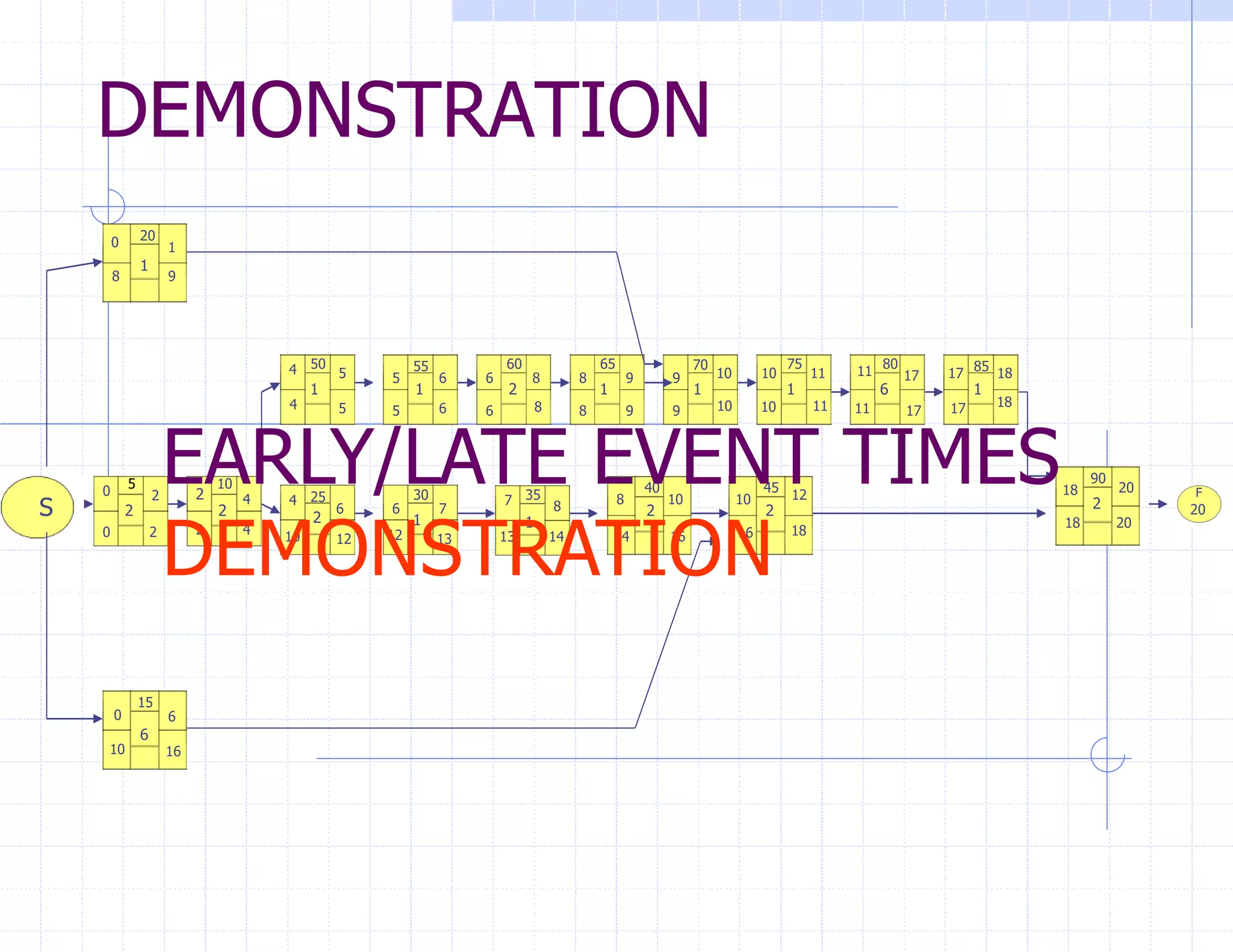

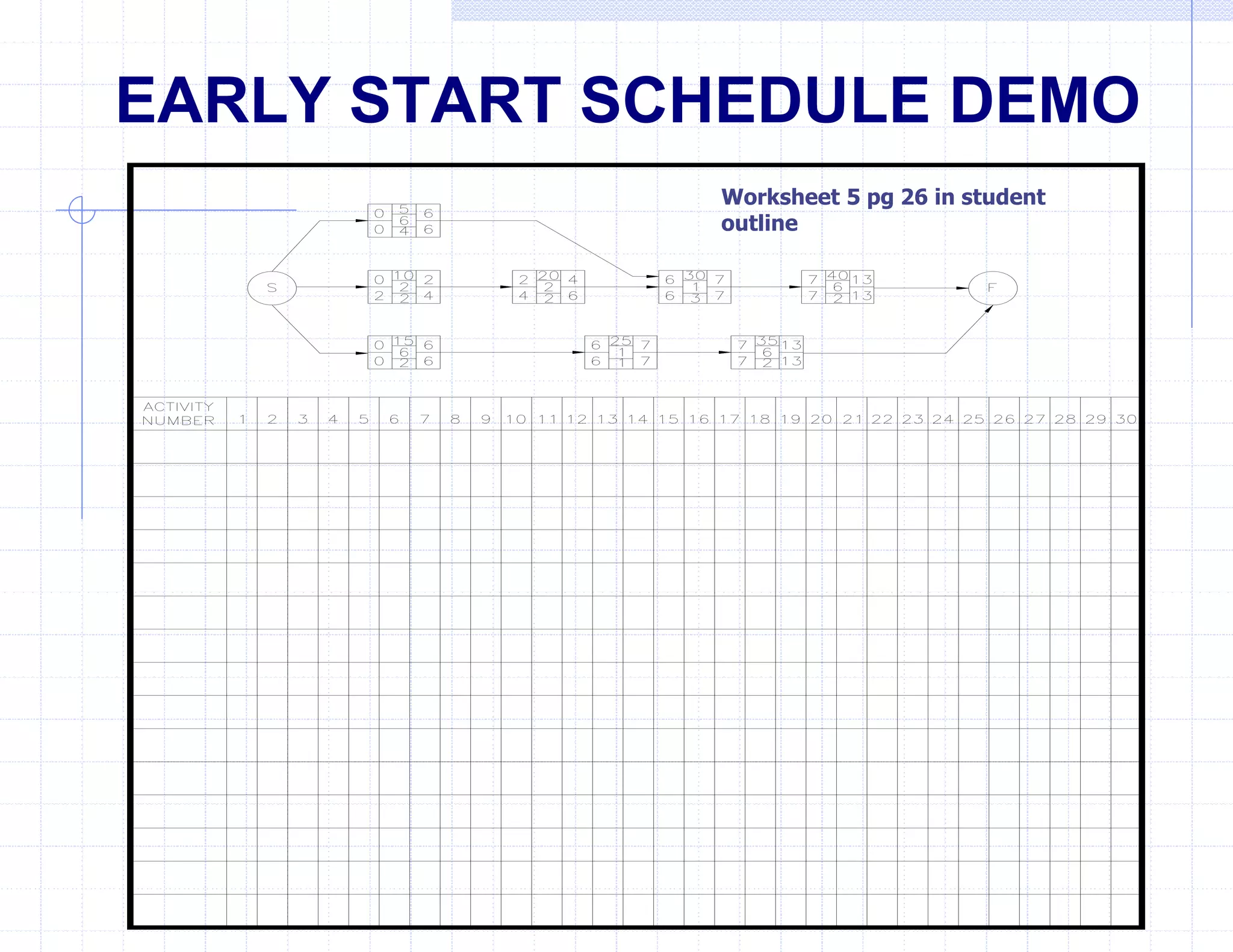

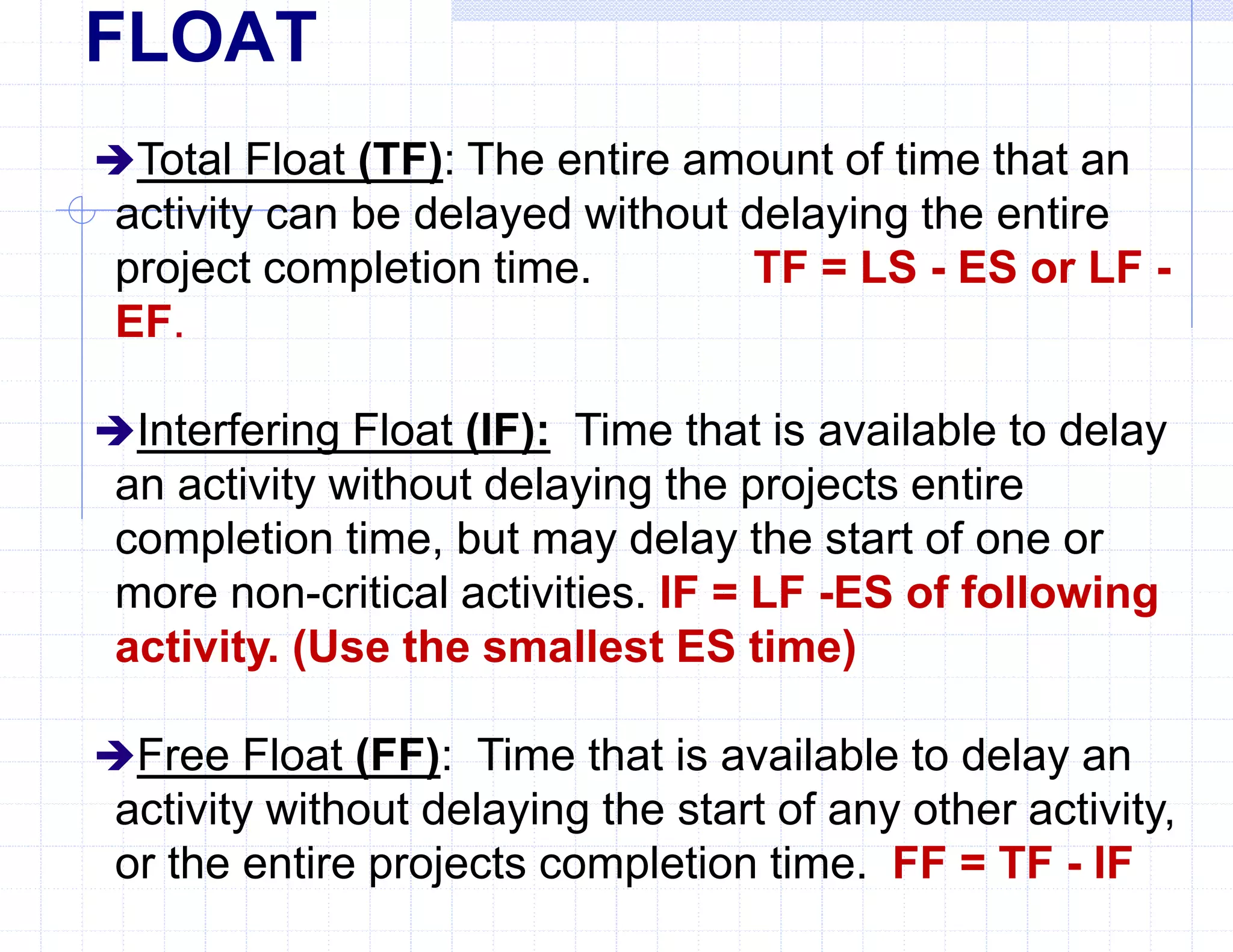

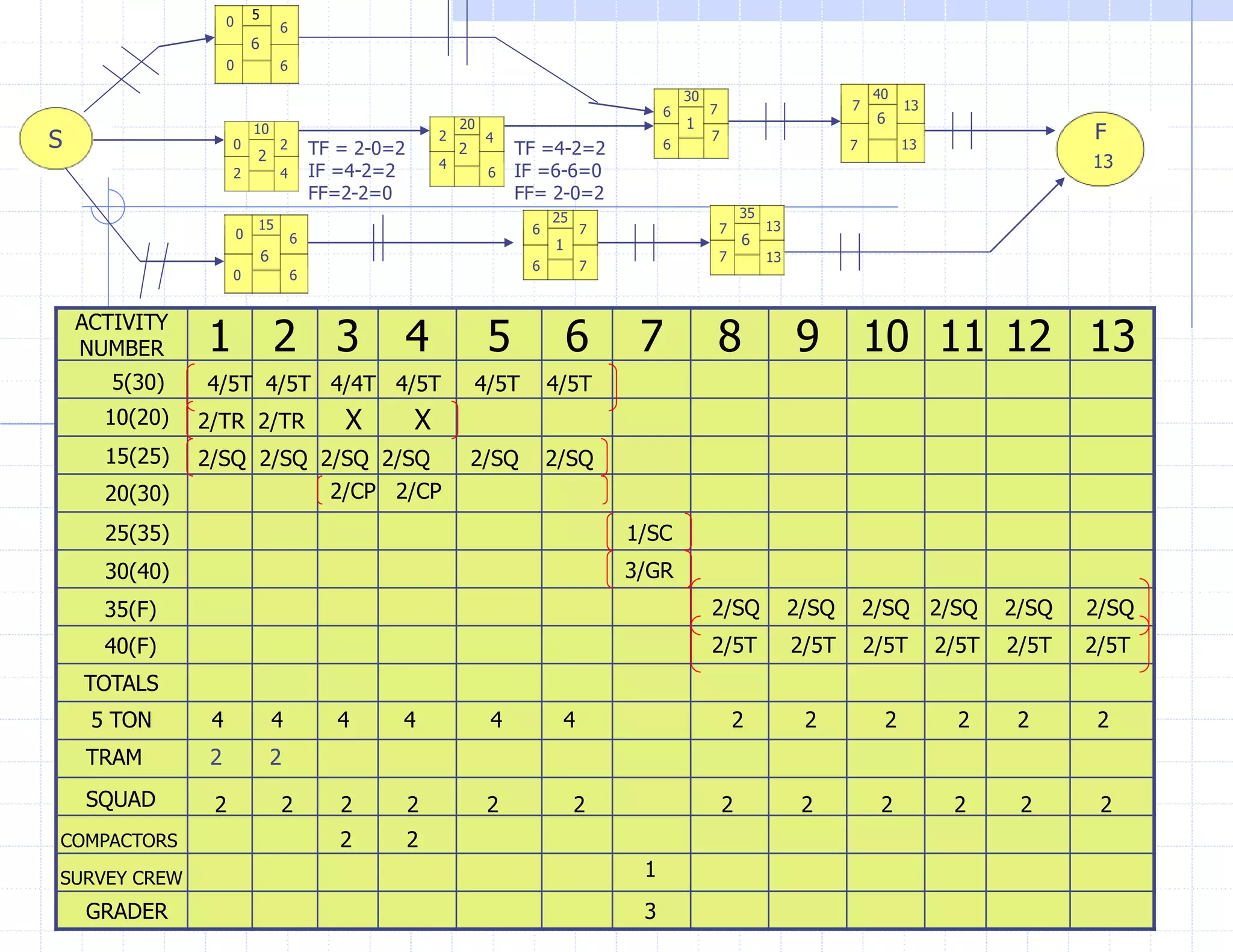

The document provides information on construction project planning and scheduling using the Critical Path Method (CPM). It discusses preliminary and detailed planning, developing activity lists, and using different types of planning diagrams including Gantt charts, PERT charts, and logic diagrams. The Critical Path Method (CPM) uses logic diagrams and precedence relationships between activities to develop an accurate schedule for a construction project from start to finish.