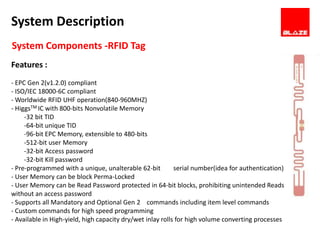

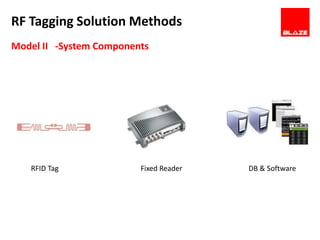

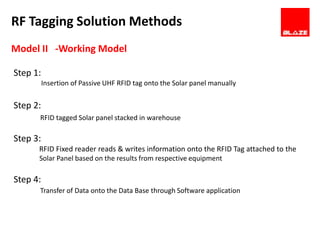

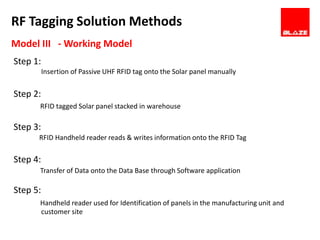

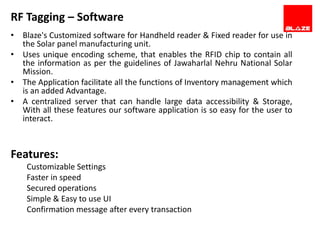

The document outlines Blaze Automation's RFID system designed for tracking and identifying solar panels in compliance with MNRE guidelines. It details the components, operation methods, and benefits of RFID tags and readers, emphasizing enhanced visibility, production efficiency, and inventory management. Blaze's solutions cater to various manufacturer requirements, ultimately aiming to improve productivity and asset visibility in the solar panel industry.