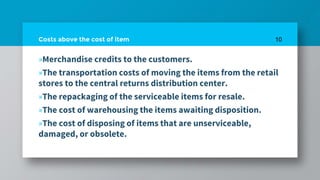

The document provides an overview of reverse logistics from the perspectives of operations and challenges. It discusses key aspects of reverse logistics including typical activities, costs, and impact. It notes that reverse logistics is an emerging industry that presents challenges for operations people due to the many stakeholders involved and lack of standardized processes. Best practices discussed include having one group control returns and defined business processes to improve efficiency. The document also provides examples of Flipkart's reverse logistics network and return process.