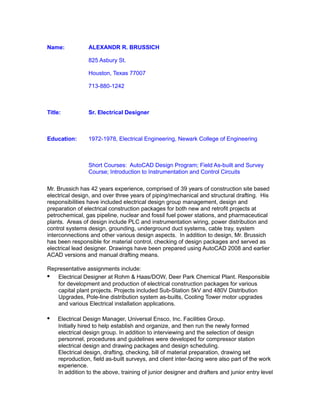

Alexand Brussich is a senior electrical designer with over 42 years of experience in electrical design, drafting, and project management for various industrial plants. He has extensive experience designing electrical systems for petrochemical, gas pipeline, power, and pharmaceutical facilities. His responsibilities have included managing electrical design groups, developing construction packages, and serving as a lead designer. He is proficient in AutoCAD and has worked on projects involving instrumentation, power distribution, control systems, and more.