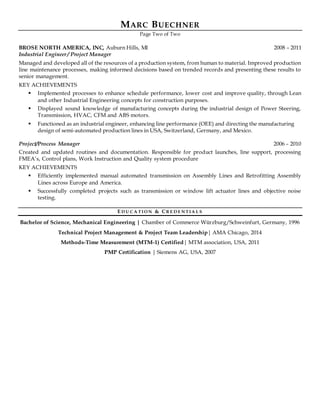

This document summarizes the experience and qualifications of Marc Buechner as a senior-level project manager with over 20 years of experience in product design, project management, and process engineering. He has a proven track record of successfully delivering engineering projects on time and on budget, improving efficiency, reducing costs, and ensuring quality standards. Buechner is proficient in various project management and engineering tools and holds credentials in project management, lean manufacturing, and other related fields. He currently serves as a Project Manager at Thyssenkrupp Presta, where he spearheads new product development initiatives and process improvements.