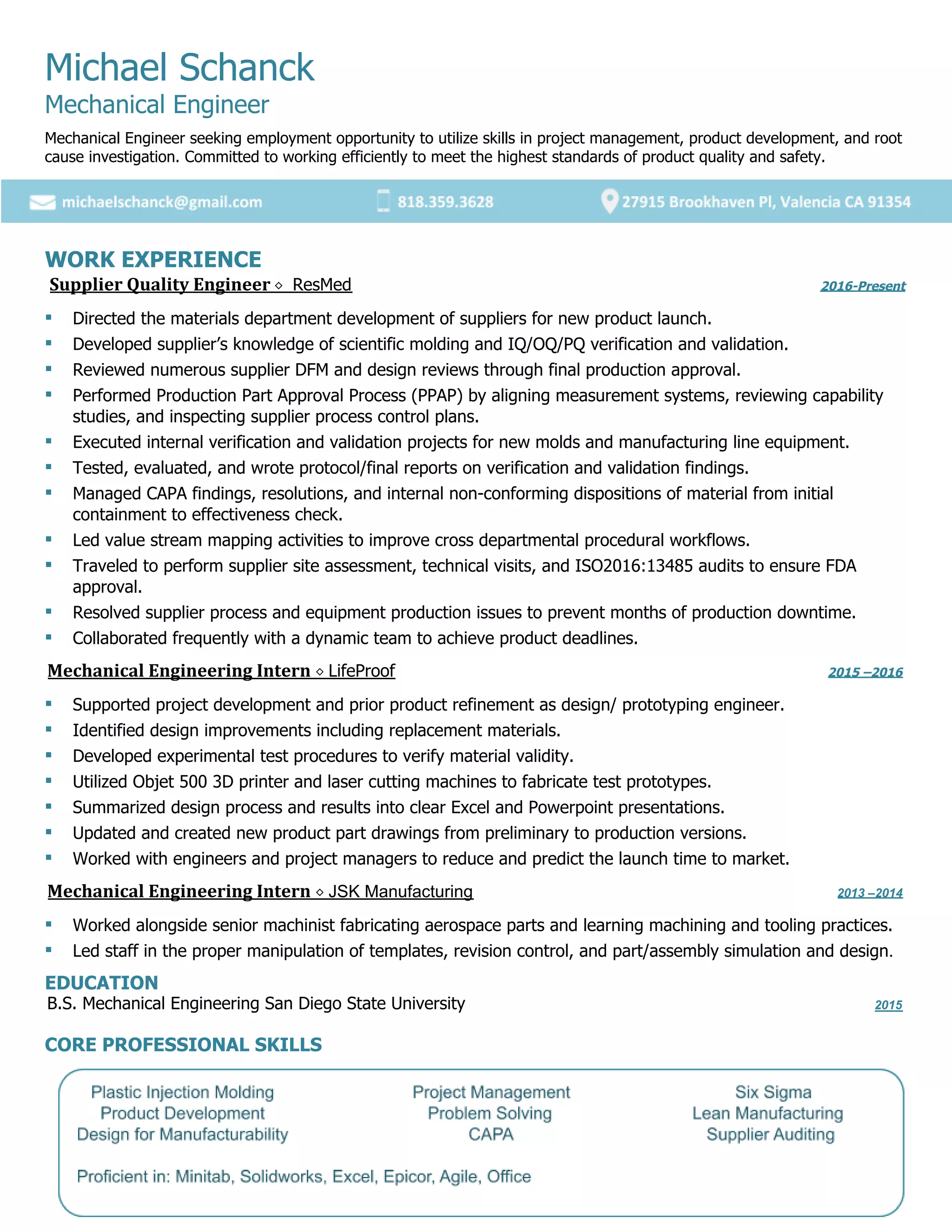

Michael Schanck is a mechanical engineer seeking a new position utilizing his skills in project management, product development, and root cause investigation. He has over 5 years of experience as a Supplier Quality Engineer at ResMed where he directed materials development for new products, developed supplier knowledge of manufacturing processes, and resolved issues to prevent production downtimes. Previously he held internships at LifeProof and JSK Manufacturing where he supported product development, identified design improvements, developed testing procedures, and learned machining practices. He has a B.S. in Mechanical Engineering from San Diego State University.