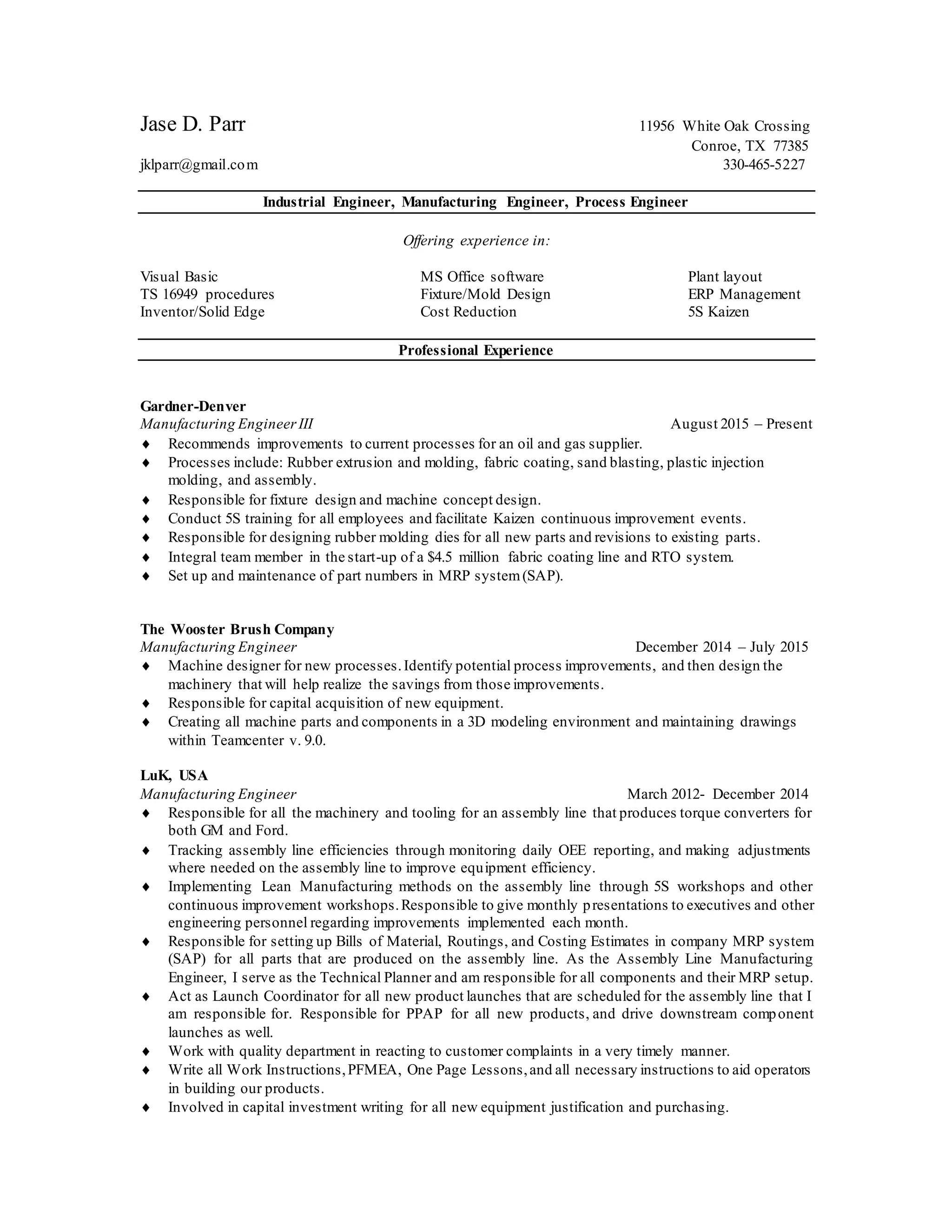

Jase D. Parr has over 20 years of experience in manufacturing engineering roles. He has worked for several companies in various industries, taking on responsibilities such as process improvement, equipment design, Lean initiatives, and project management. Parr's background includes experience with ERP systems, cost reduction, safety management, and production supervision. He holds a Bachelor's degree in Industrial Technology from Ohio University.