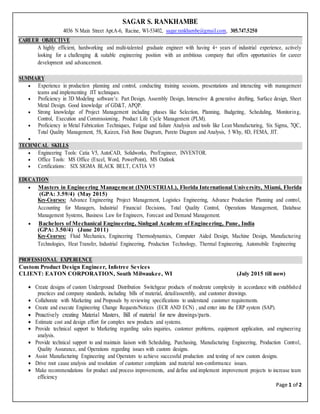

Sagar Rankhambe is seeking an engineering position utilizing his 4+ years of experience in production planning, quality control, project management, and CAD design. He has a Master's in Engineering Management and is proficient in Catia V5, AutoCAD, Solidworks, and Six Sigma methods. His experience includes custom product design for Eaton Corporation, product design and development for Neodes India, and production planning and quality assurance for TBK India.