1) Balamurgan Kalidass is a mechanical engineer with over 3 years of experience in quality control for mechanical fabrication and erection projects.

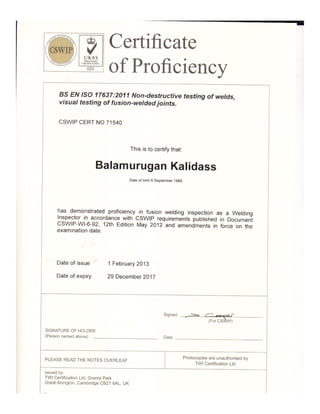

2) He holds certifications in welding inspection and non-destructive testing.

3) His most recent role was as a welding inspector from March 2014 to November 2014 for a power plant project in Saudi Arabia, where he performed various quality control and inspection duties.