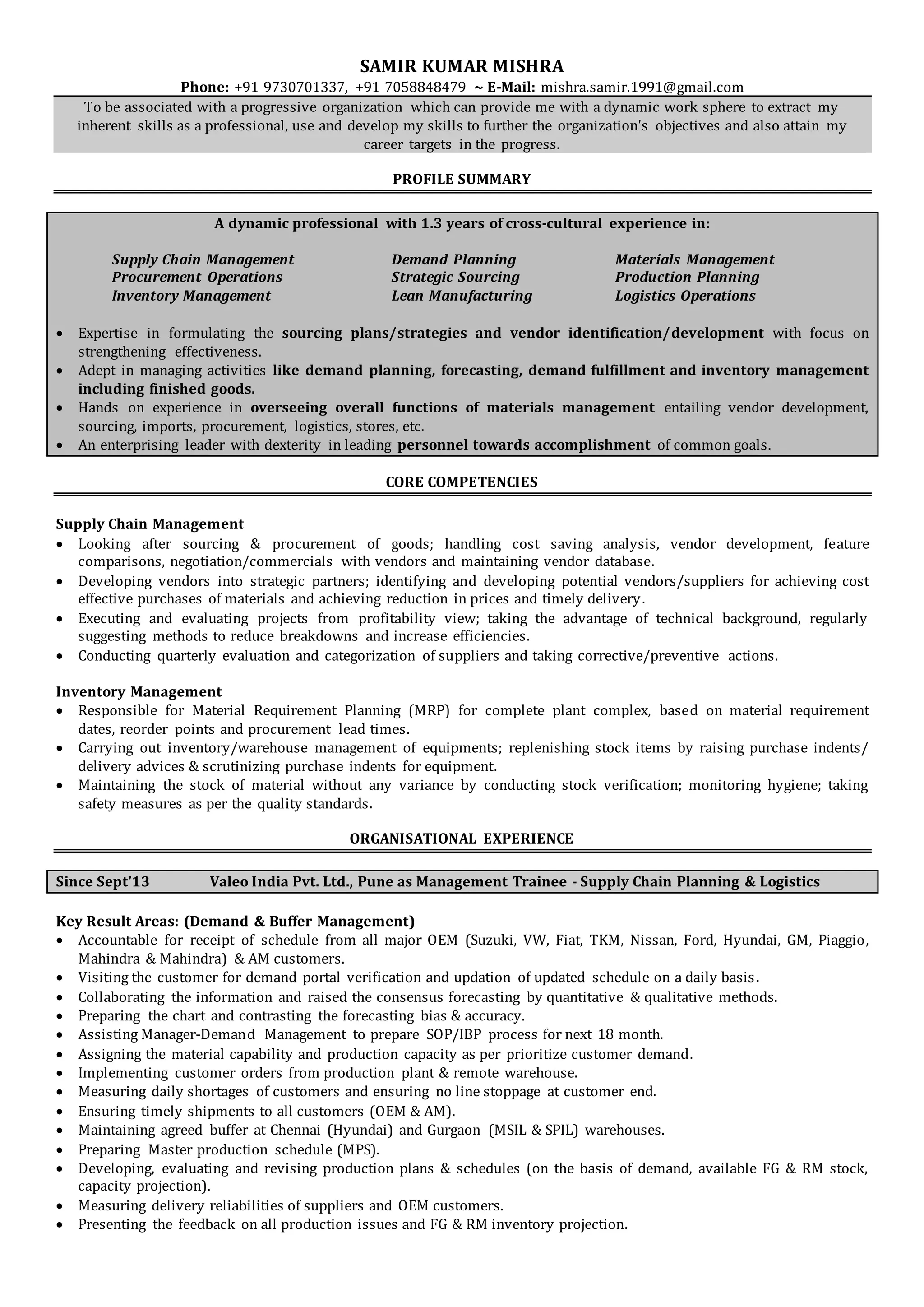

This document is a resume for Samir Kumar Mishra seeking a position utilizing his 1.3 years of experience in supply chain management, demand planning, materials management, procurement, and inventory management. He has expertise in sourcing, vendor development, demand forecasting, inventory management, and overseeing materials functions. His most recent role was as a Management Trainee in supply chain planning and logistics at Valeo India Pvt. Ltd. where he was responsible for demand management, production planning, materials planning and control, and ensuring on-time deliveries.