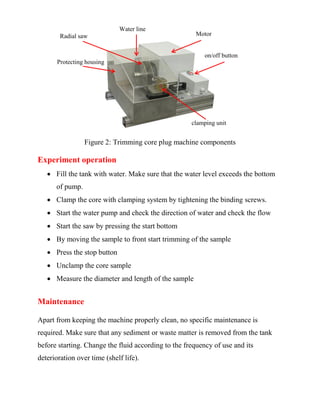

This document provides instructions for using a trimming core plug machine to cut rock core samples to a desired size. The machine uses two radial saws that can cut both ends of a core plug simultaneously with cooling water. Safety precautions when using the machine include not touching the cutting wheels and only operating it when the hood is closed. The experiment involves clamping the core sample, starting the water pump, trimming the sample with the saw, unclamping the sample, and measuring its diameter and length. Basic maintenance is to keep the machine clean and change the fluid as needed.