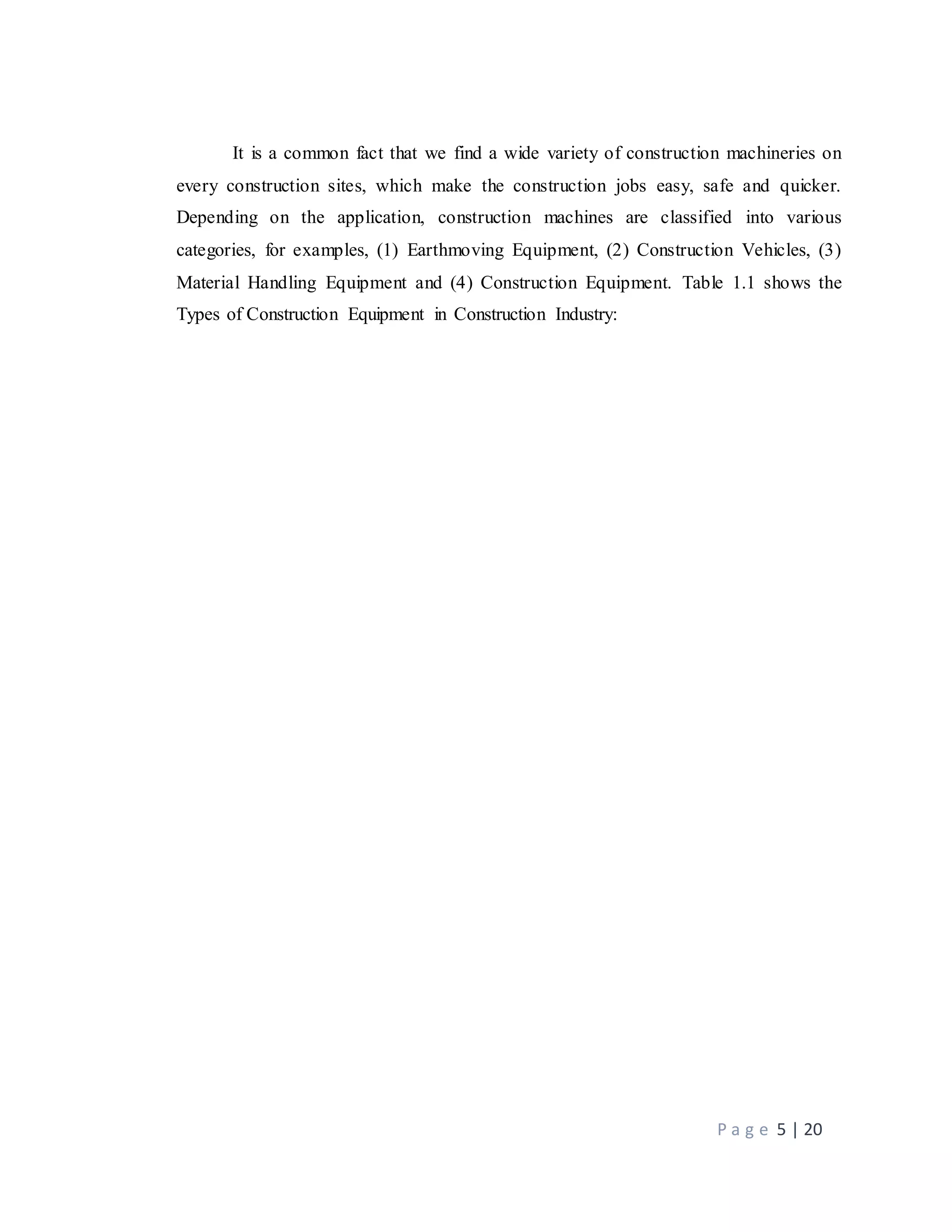

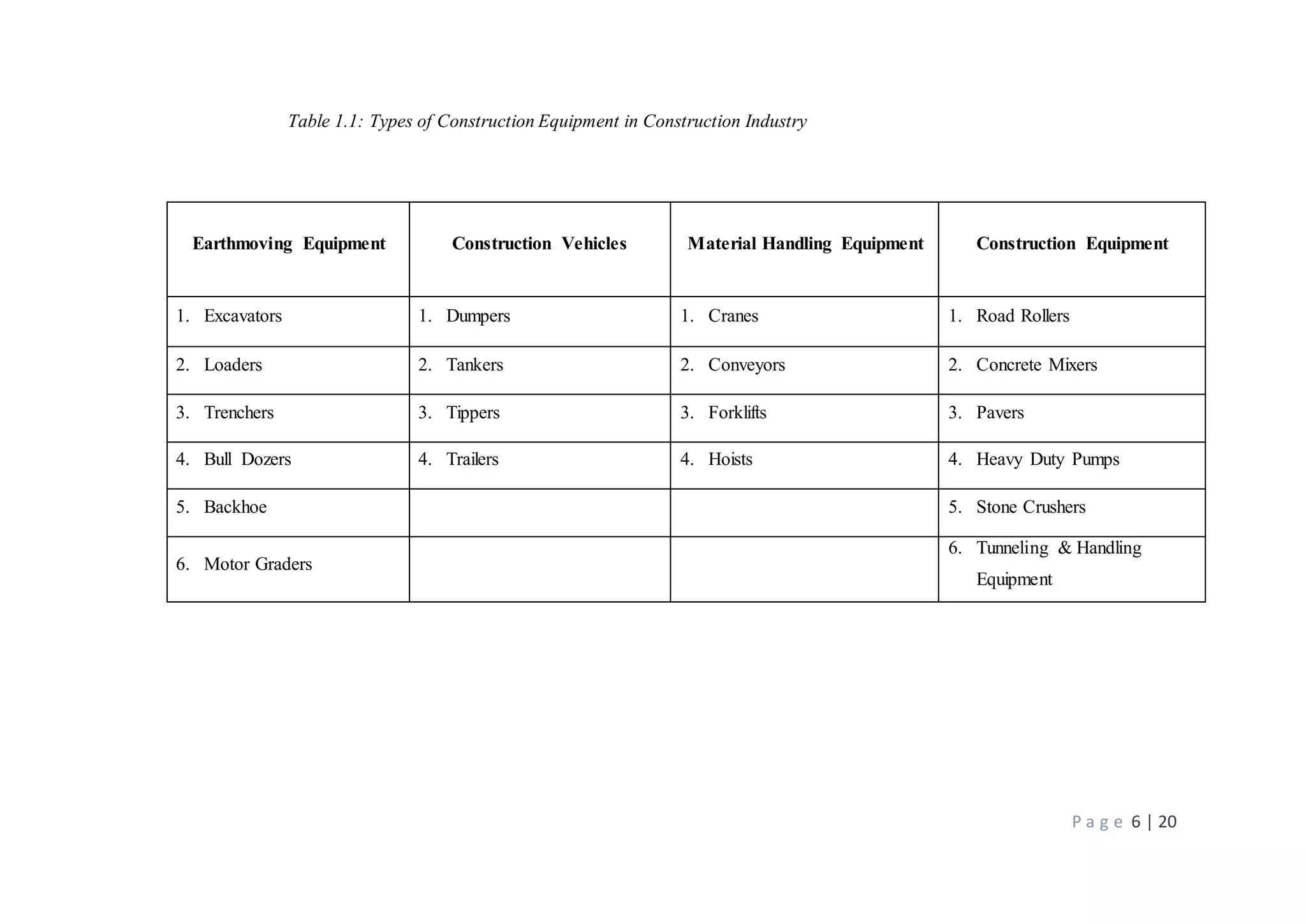

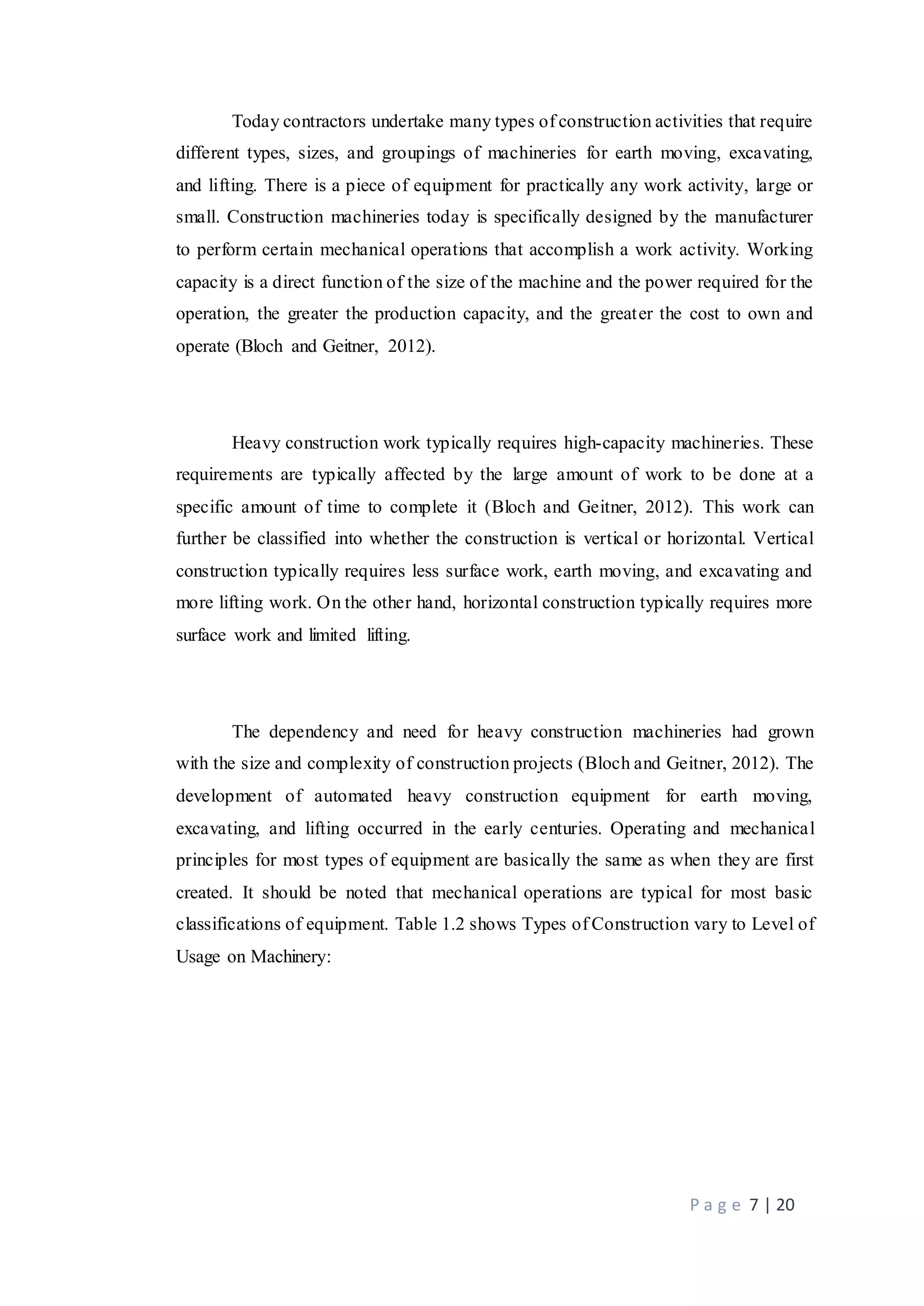

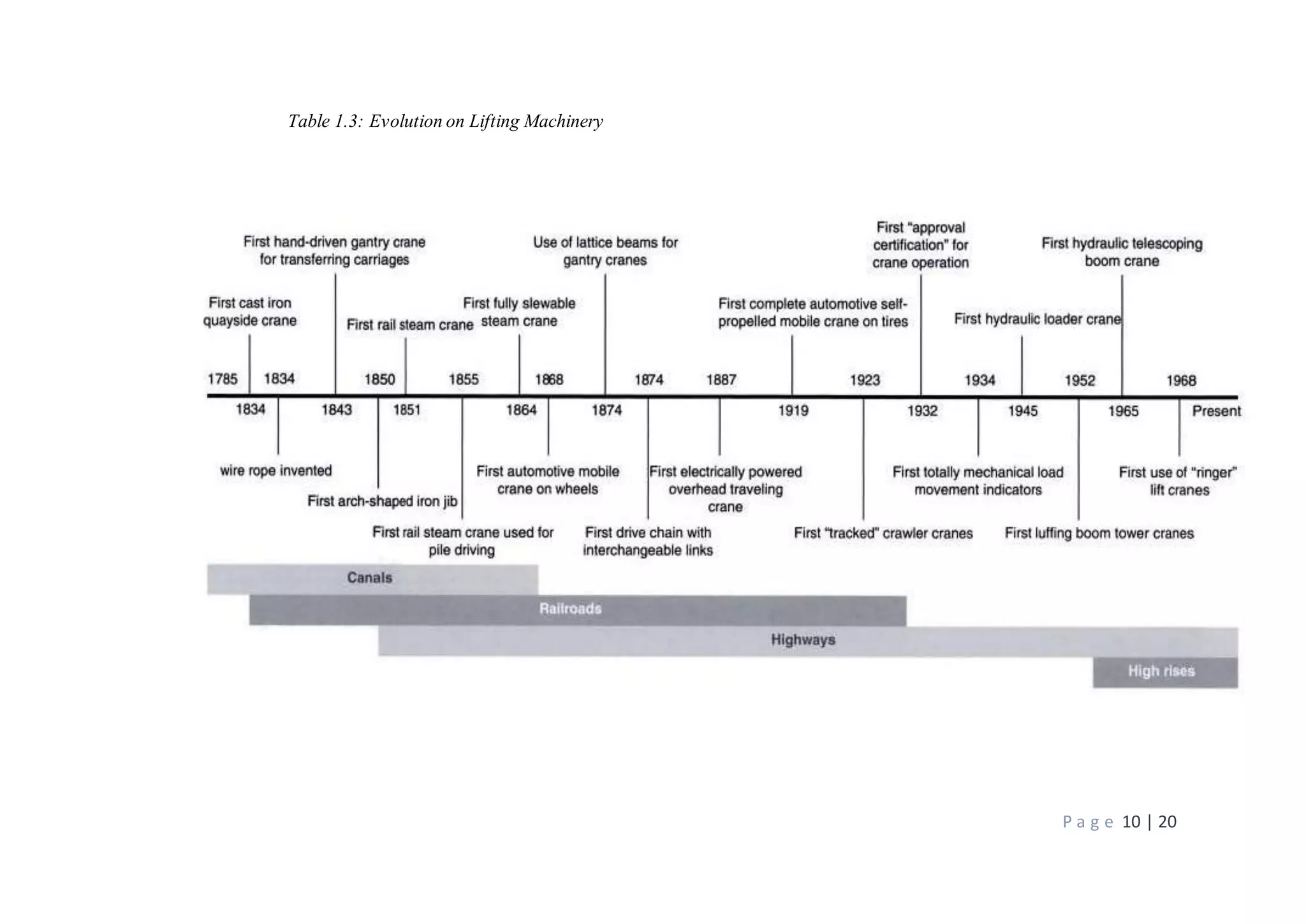

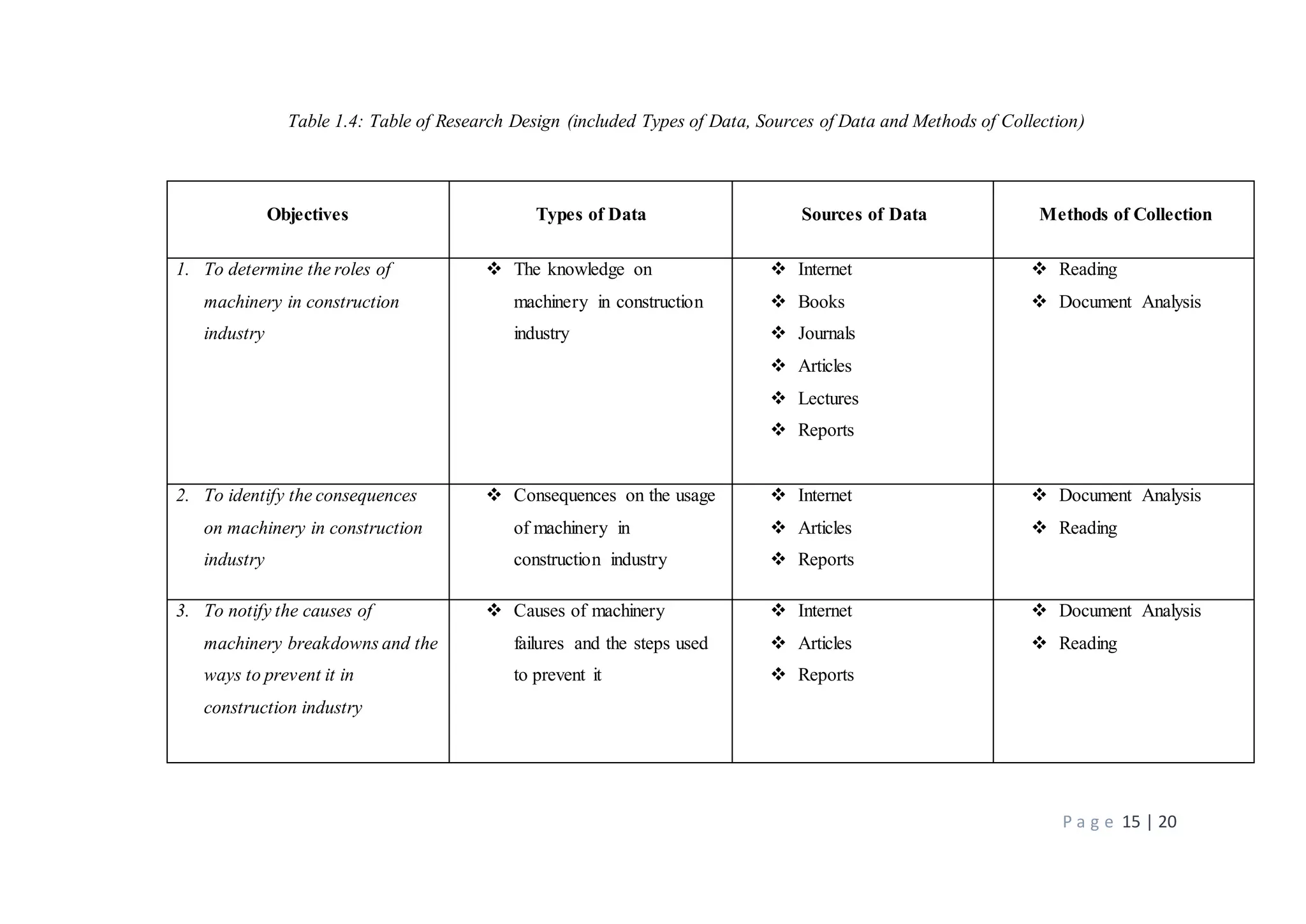

This document presents a research proposal on the role of machinery in the construction industry. It includes an introduction that provides background on construction and the importance of machinery. It discusses different types of construction equipment and how machinery usage varies based on the type of construction project. The introduction also covers the evolution of lifting machinery over time. The document identifies the need to study causes of machinery failures and ways to prevent them. Some potential causes of failure discussed are poor training, overrunning a machine's capabilities, mechanical defects, and improper maintenance. The introduction concludes by stating the problem statement will focus on these failure causes.

![P a g e 20 | 20

References

1 Bloch, H. and Geitner, F. (2012). Machinery failure analysis and troubleshooting.

Oxford: Butterworth-Heinemann.

2 Gransberg, D., Popescu, C. and Ryan, R. (2006). Construction equipment

management for engineers, estimators, and owners. Boca Raton, FL: CRC

Taylor & Francis.

3 Friedmann, A. (2014). Causes Of Heavy Machinery | Construction Sites |

Disability. [online] Phillydisabilitylawyer.com. Available at:

http://phillydisabilitylawyer.com/causes-heavy-machinery-accidents/ [Accessed

28 Oct. 2015].

4 Wehrspann, J. (2015). 10 biggest causes of machinery breakdowns (and how to

prevent them). [online] Farmindustrynews.com. Available at:

http://farmindustrynews.com/planters/10-biggest-causes-machinery-breakdowns-

and-how-prevent-them [Accessed 28 Oct. 2015].

5 Hhilifting.com, (2015). Importance of Construction Industry in the Economy and

Use of Construction Equipments | HHI Lifting. [online] Available at:

http://www.hhilifting.com/importance-of-construction-industry-in-the-economy-

and-use-of-construction-equipments/ [Accessed 28 Oct. 2015].

6 Danso, H. (2014). Poor Workmanship and Lack of plant/Equipment Problems in

the Construction Industry, 2(3), pp.60-70.](https://image.slidesharecdn.com/researchmethodologyintroductionchapter1-151202094002-lva1-app6892/75/Research-Methodology-Introduction-Chapter-1-20-2048.jpg)