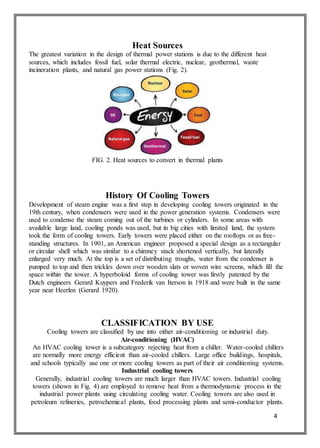

This document summarizes the types, working principles, and applications of cooling towers. It discusses natural and mechanical draft cooling towers, as well as dry, wet, and hybrid heat transfer methods. The key components and processes of power plants that utilize cooling towers are also overviewed. Different sizes, designs, and environmental impacts of cooling towers are addressed.