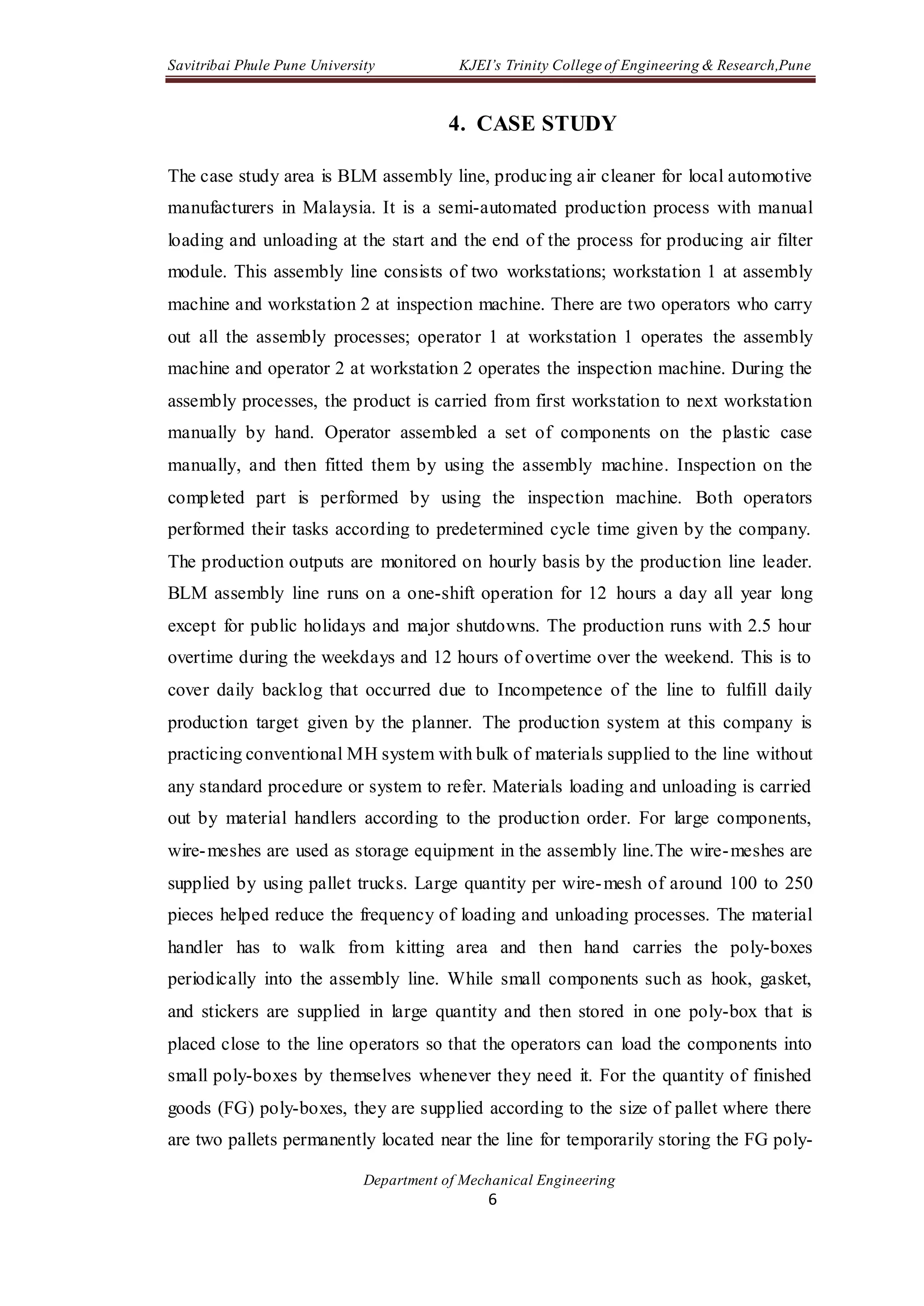

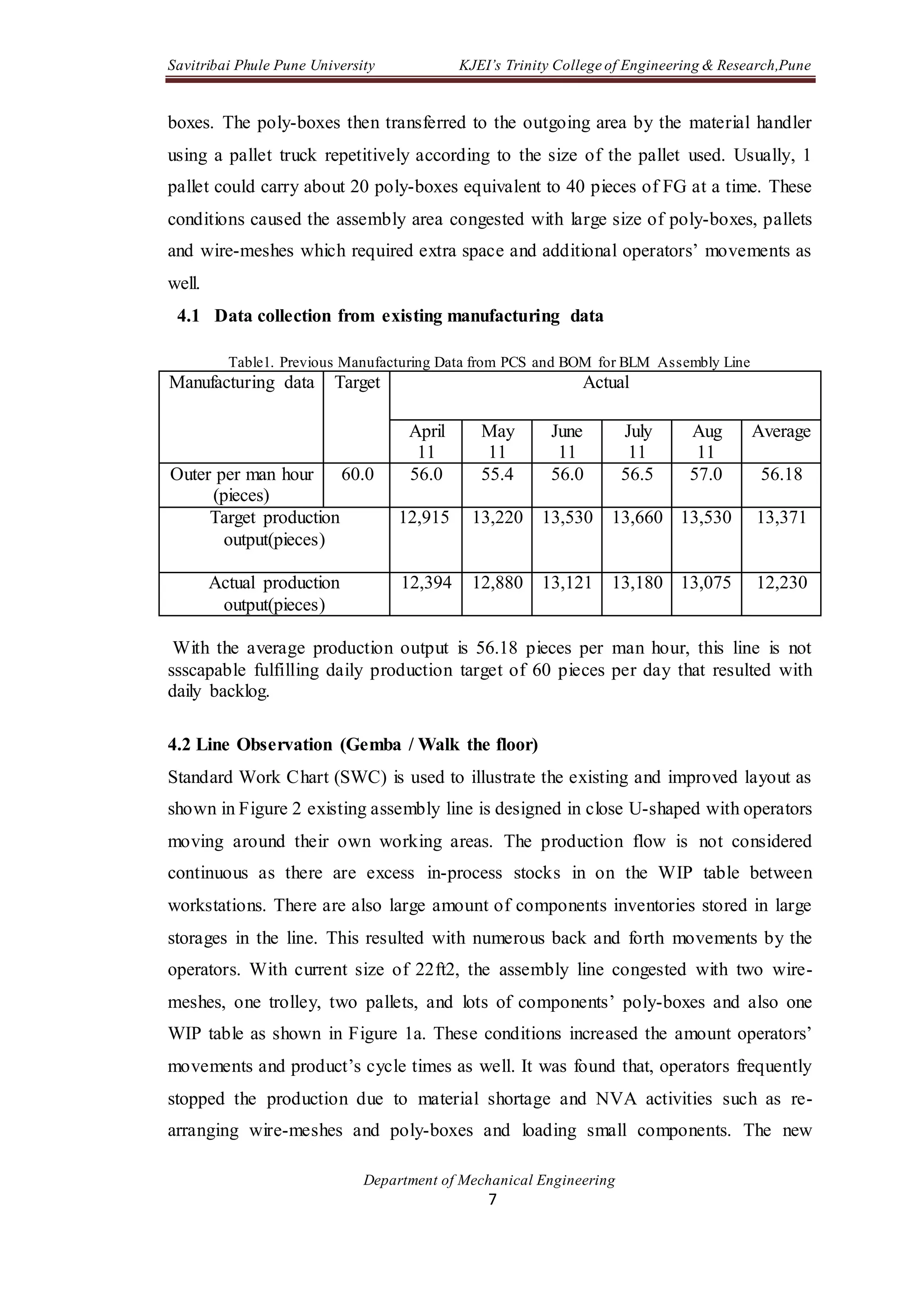

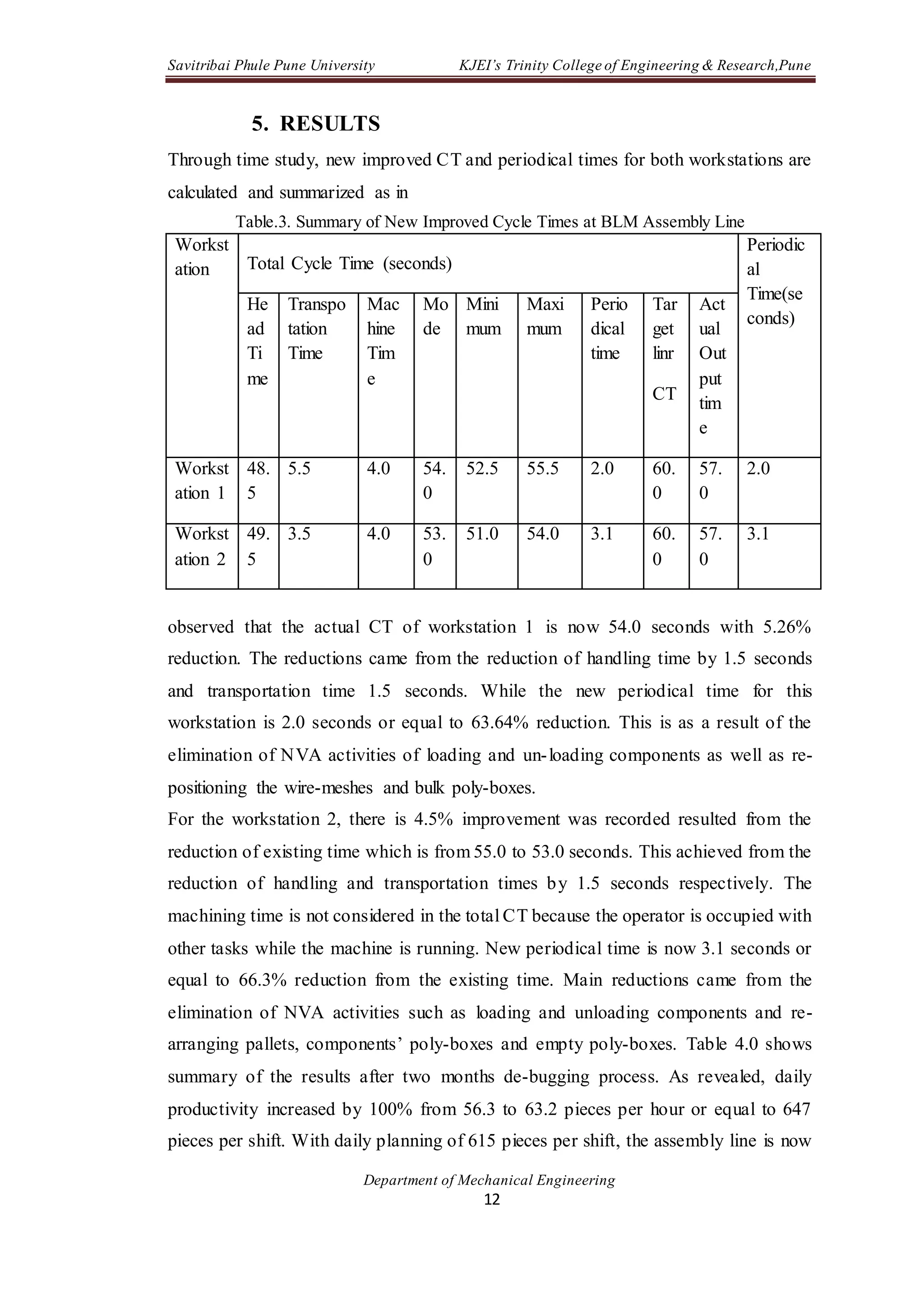

The document discusses the Just-In-Time (JIT) management philosophy, which aims to minimize manufacturing waste by ensuring that the right part is produced in the right place at the right time, thereby improving efficiency and quality while reducing costs. Originating from Japan and exemplified by Toyota, JIT emphasizes team involvement, quality control at the source, and systematic elimination of waste including overproduction and waiting times. A case study highlights the application of JIT principles in a Malaysian assembly line, detailing the benefits of an improved layout and the implementation of gravity flow rack systems to enhance production efficiency.

![Savitribai Phule Pune University KJEI’s Trinity College of Engineering & Research,Pune

Department of Mechanical Engineering

10

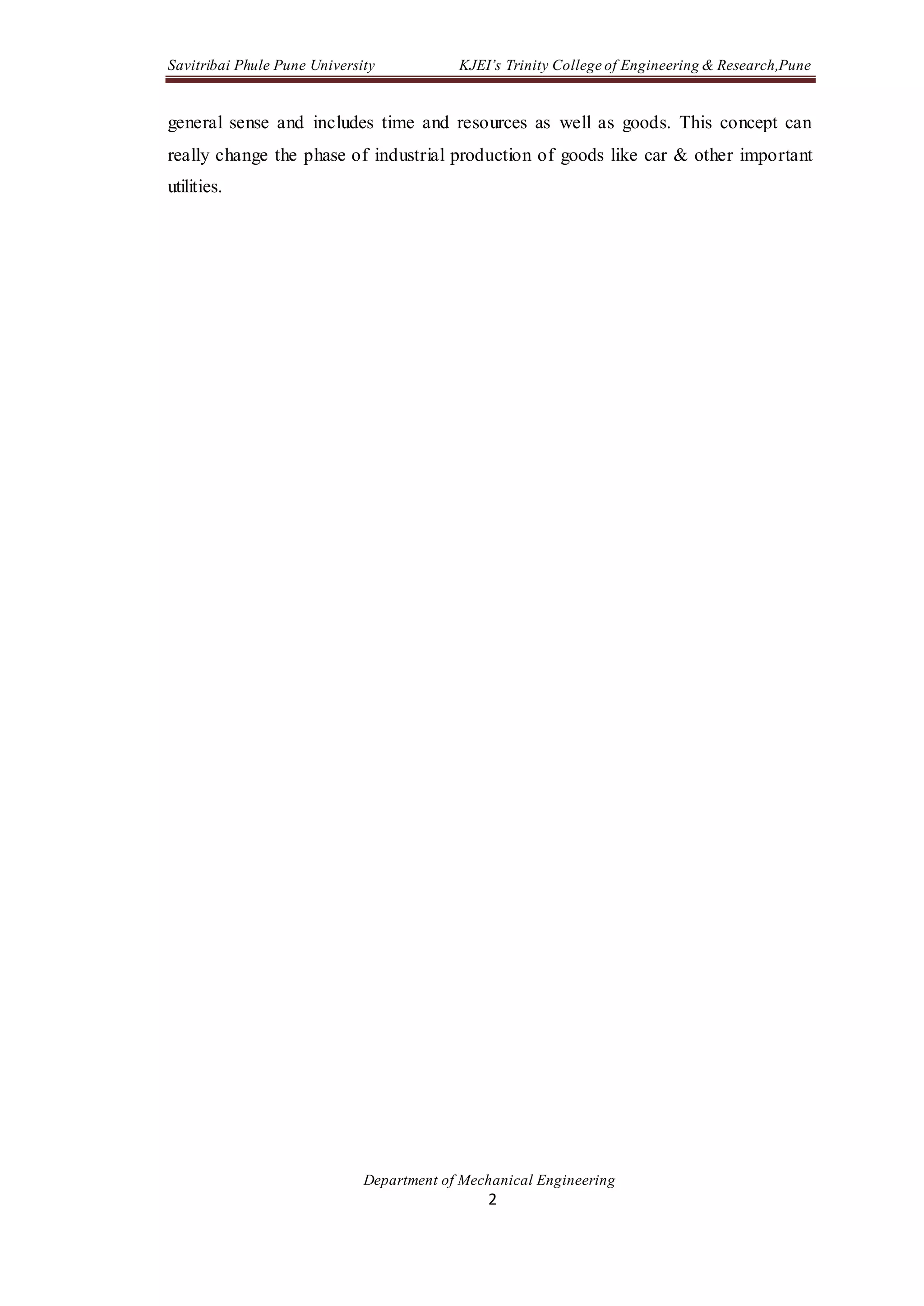

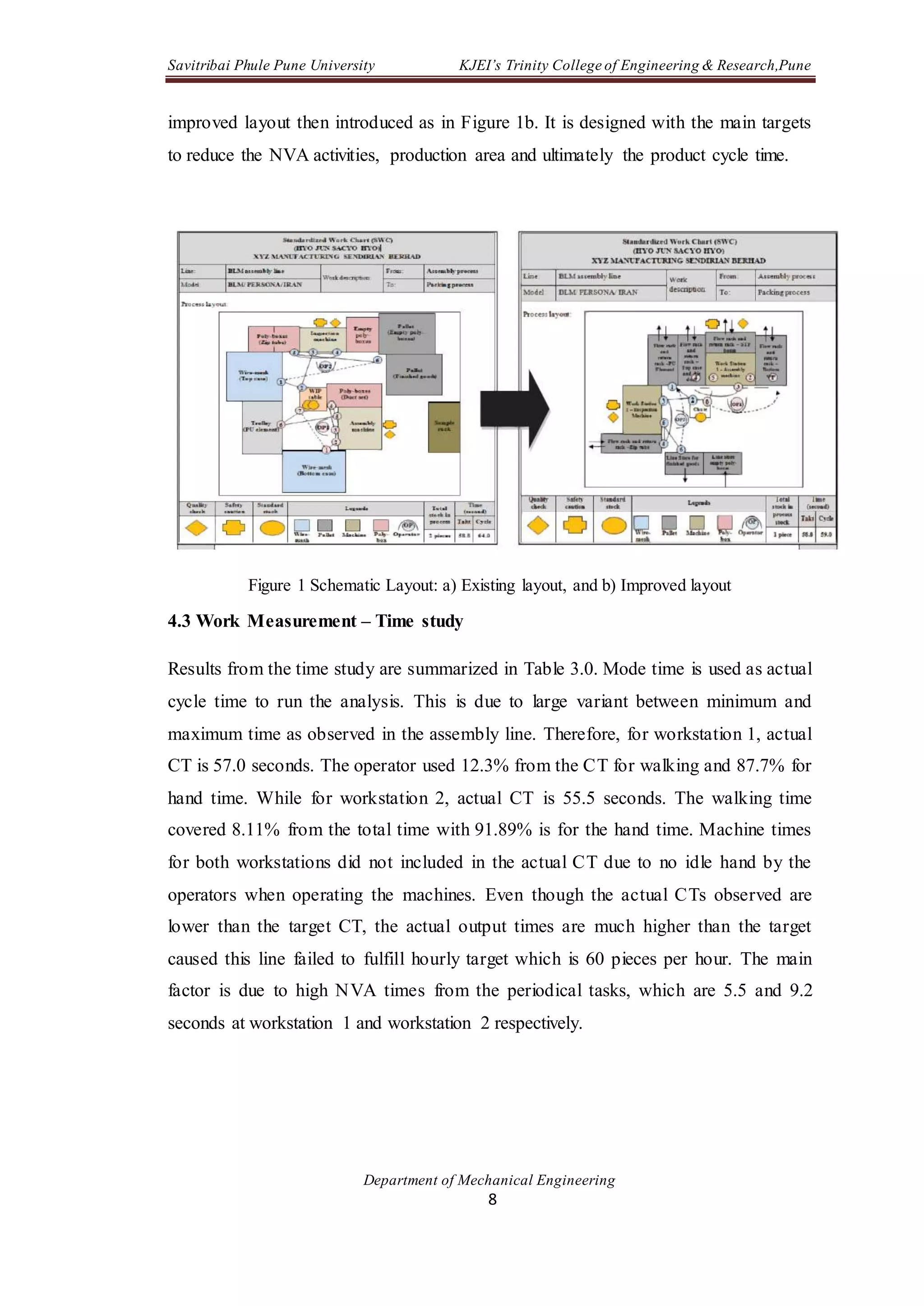

There are different sizes of poly-boxes for different sizes of components, thus the

GFR was designed according to the following details; i) location size, ii) poly-boxes

weight, length, width and height, iii) standard quantity per poly-box, iv)number of

poly-boxes used per hour, v) delivery frequency and quantity vi) cycle time for each

delivery process, and vii)maximum poly-boxes quantity on the GFR at one time. This

is mainly to allow minimum quantity of components to be supplied at the same time

and to reduce size of the flow rack. This system is also extended to the line storage

area so that the FG poly-boxes could be replenished from off line. With this

implementation, the pallet system which was used previously permanently discarded

from the assembly line. Figure 4.0 show examples of the GFR system for different

types of components and FG poly-boxes in the assembly line.

Fig3. GFR System: a) Large Components, b) Medium Components, and c) FG Poly-boxes

To optimize the effectiveness of GFR system, a series of kaizen activities were

conducted as follows [12]:

1. Simplify and re-arrange the assembly processes: Current assembly processes

were simplified and re-arranged by combining the process elements and

movements where possible, as well as rearranging the process sequence and

simplifying the processes.

ii. Elimination of NVA activities: The NVA activity such as loading the components

has been replaced by the GFR system. While, transferring of FG poly-boxes onto the

line store which were manually done by operator 2 has been improved by a special

designed trolley as in Figure 5.0. The trolley is designed according to the size of the

FG poly-boxes and at the same height level with the line store. From this, the

transferring process could be carried out without the operator having to pick-up and](https://image.slidesharecdn.com/report-170421081025/75/Report-on-JIT-for-Projects-and-Seminars-10-2048.jpg)

![Savitribai Phule Pune University KJEI’s Trinity College of Engineering & Research,Pune

Department of Mechanical Engineering

21

REFERANCES

[1] Nurul Hayati Abdul Halim*, Ahmed Jaffar, Noriah Yusoff, Ahmad Naufal

Adnan

Gravity Flow Rack’s Material Handling System for Just-In-Time (JIT)

Production

Procedia Engineering 41 ( 2012 ) 1714 – 1720

[2] Muhammad Asim Mirza and Eric M. Malstrom

Required Setup Reductions In JIT Driven MRP Systems 0360-8352(94)00168-5

[3] Seung-Lae Kima,*, Daesung Hab A JIT lot-splitting model for supply chain

management: Enhancing buyer–supplier linkage

[4] Quality Assurance (Reference Book ) –D.H.Stamatis

[5] Amasaka K. New JIT: a new management technology principle at

Toyota. Int J Prod Econ 2000;80:135–44.

[6] Amasaka K. TQM-S, A new principle for TQM activities—a new

demonstrative study on science SQC, Proceedings of international

conference on production research, Bangkok, Thailand; 2000. p.1–6.

[7] Amasaka K. Proposal and implementation of the ‘‘Science SQC’’

quality control principle. Int J Math Comput Model 2003;

38(11–13):1125–36.

[8] Amasaka K. A study of flyer advertising affect when TMS-S at Toyota.

Proceedings of the 12th annual conference of the Production and

Operations Management Society, Orland, FL; 2001. p. 1–8 (CD-ROM).](https://image.slidesharecdn.com/report-170421081025/75/Report-on-JIT-for-Projects-and-Seminars-21-2048.jpg)