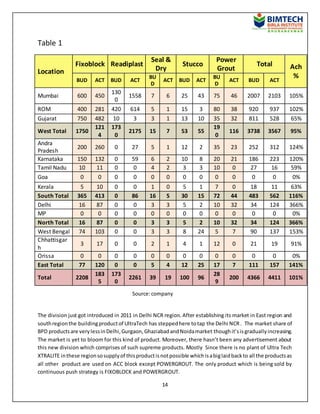

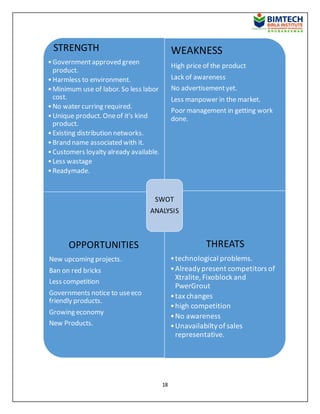

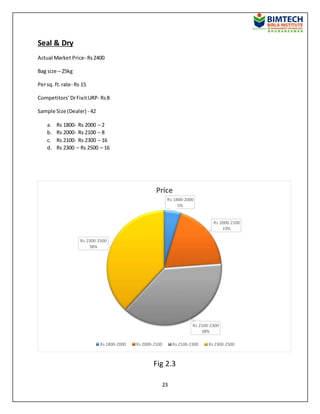

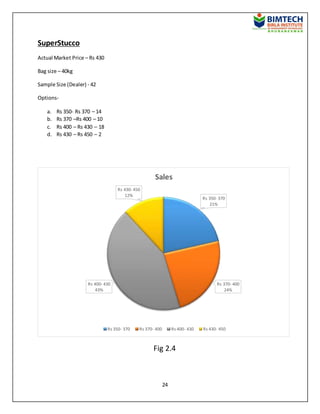

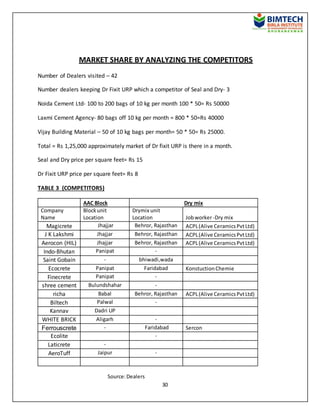

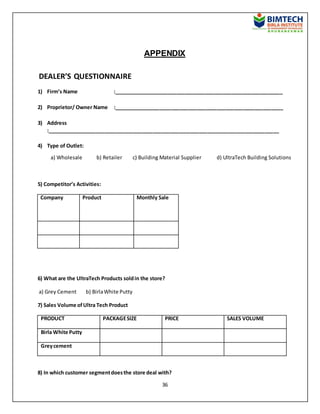

This document is a report submitted by Abhinav Nandy, a student at Birla Institute of Management Technology, as part of an internship with UltraTech Cement. The report provides an overview of UltraTech Cement and its new Building Product Division, which offers six products: UltraTech SEAL & DRY, UltraTech SUPER STUCCO, UltraTech XTRALITE, UltraTech FIXOBLOCK, UltraTech READIPLAST, and UltraTech POWERGROUT. The report then acknowledges those who assisted with the report and declares that the research was conducted ethically and authentically.