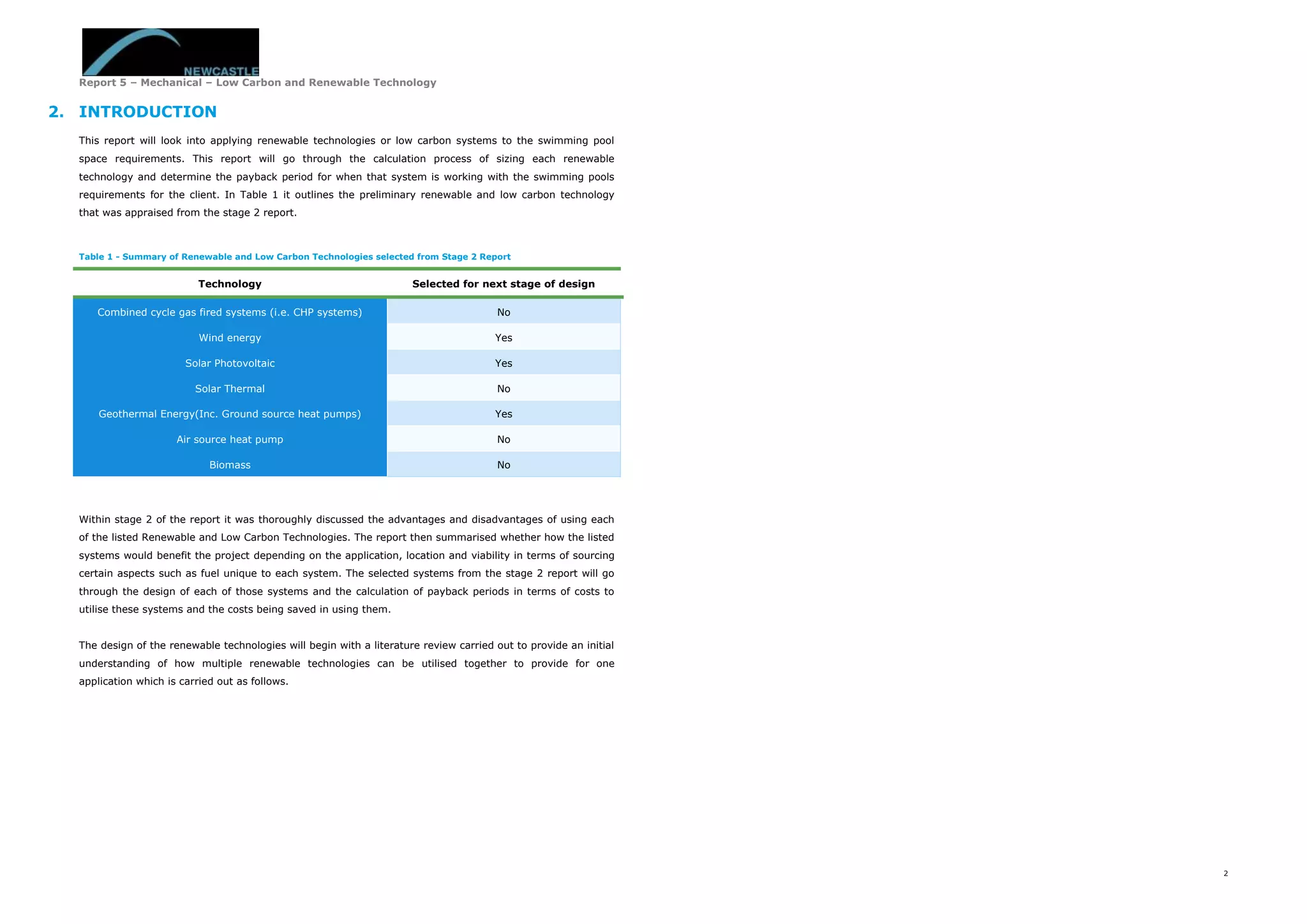

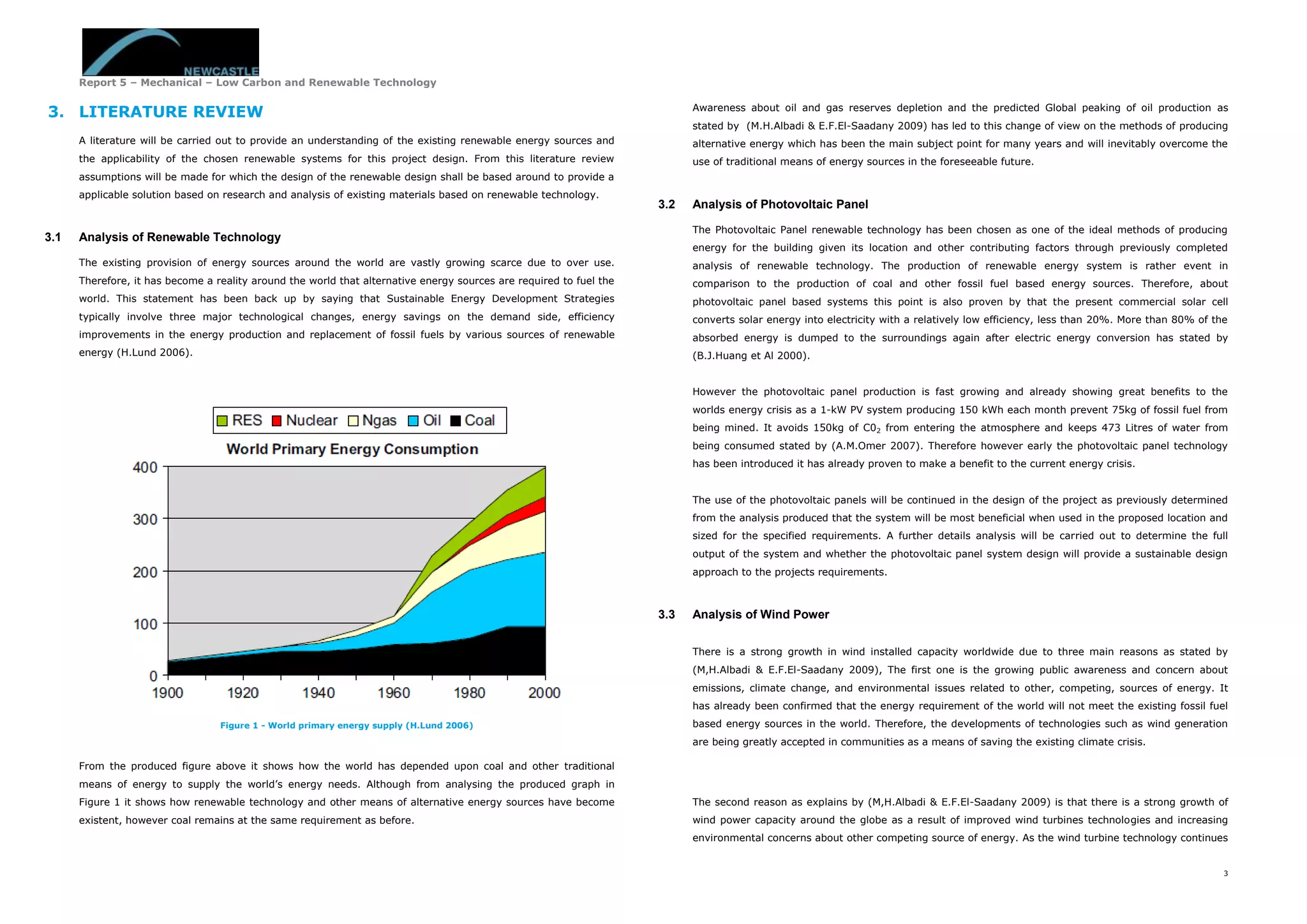

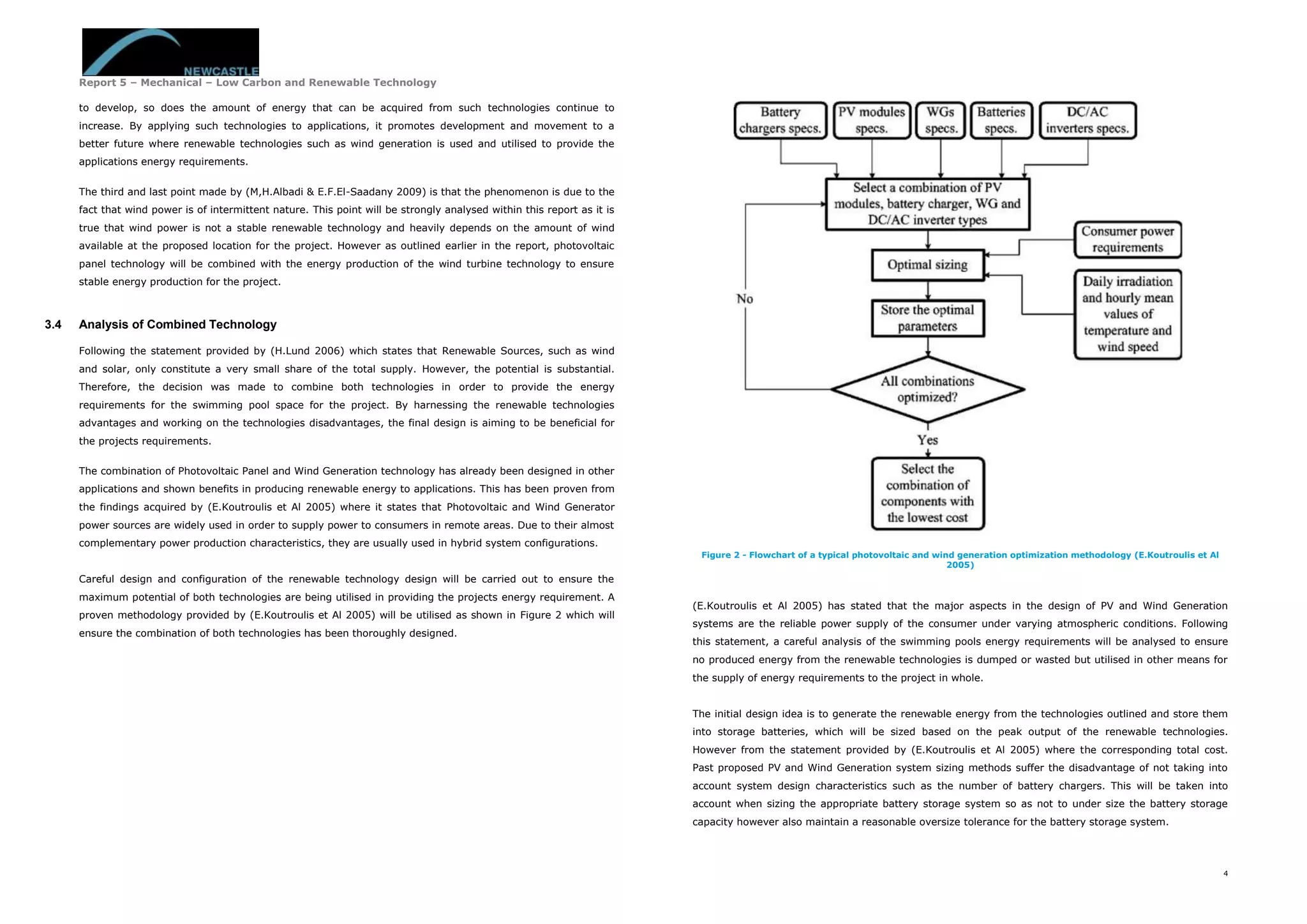

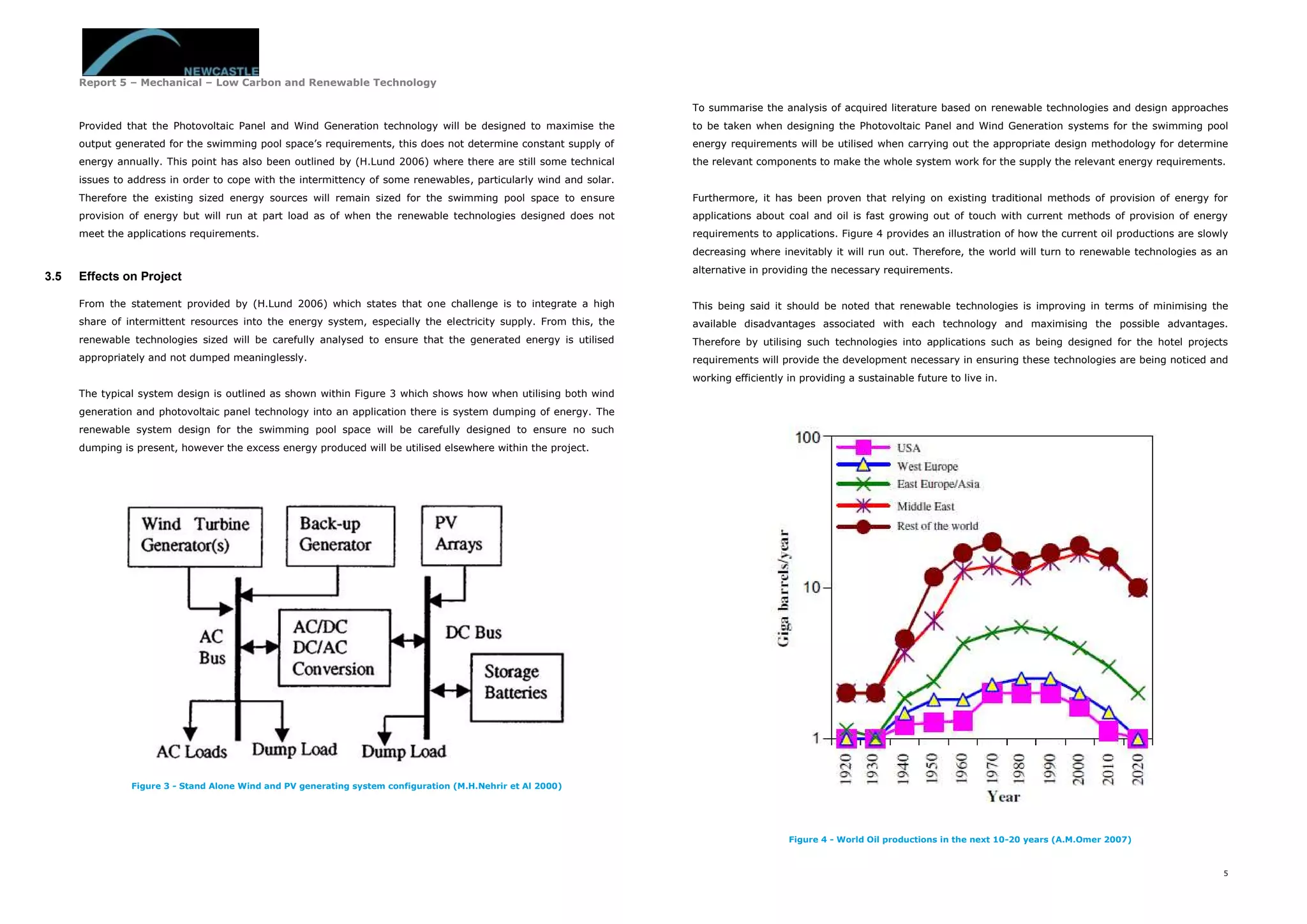

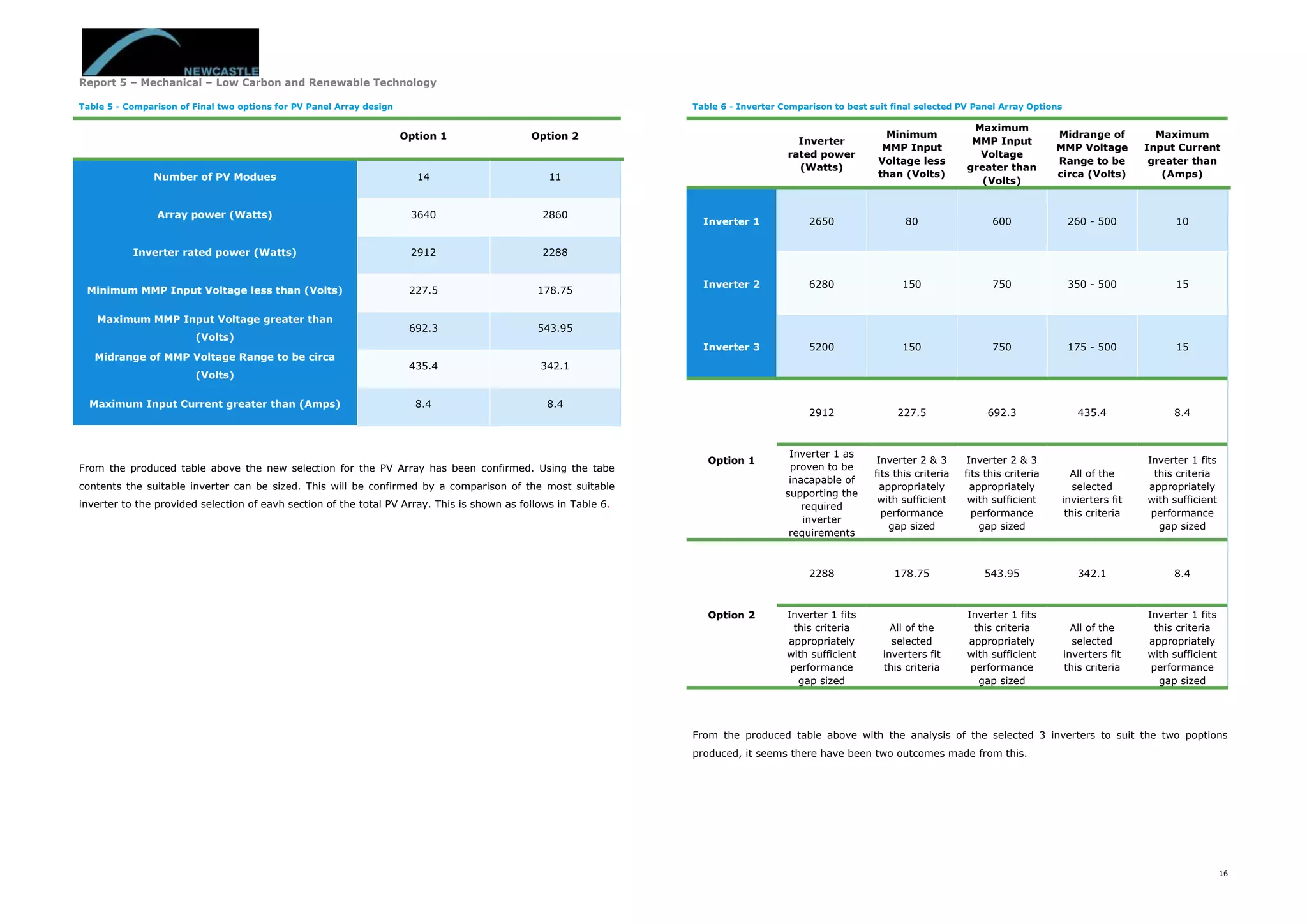

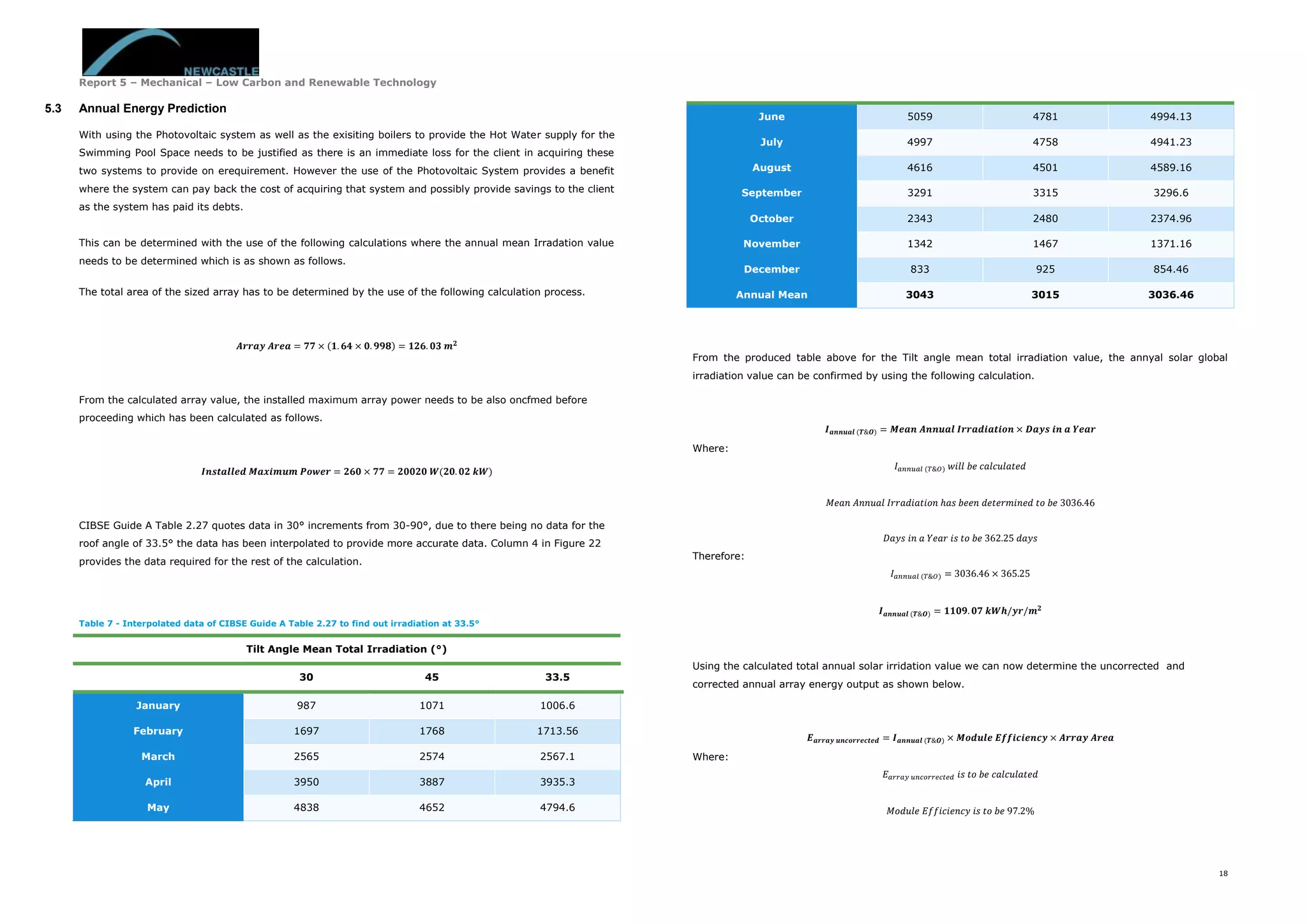

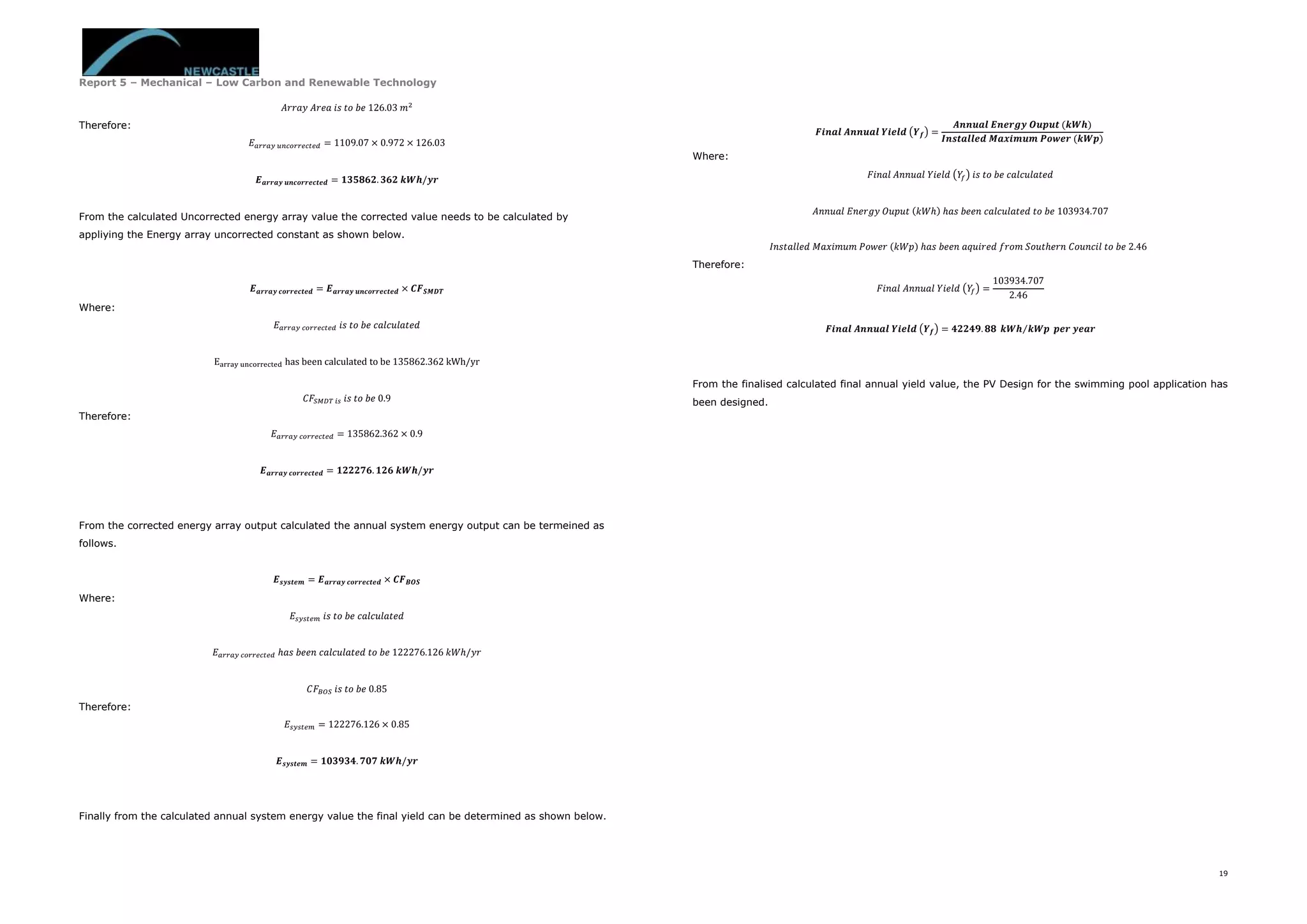

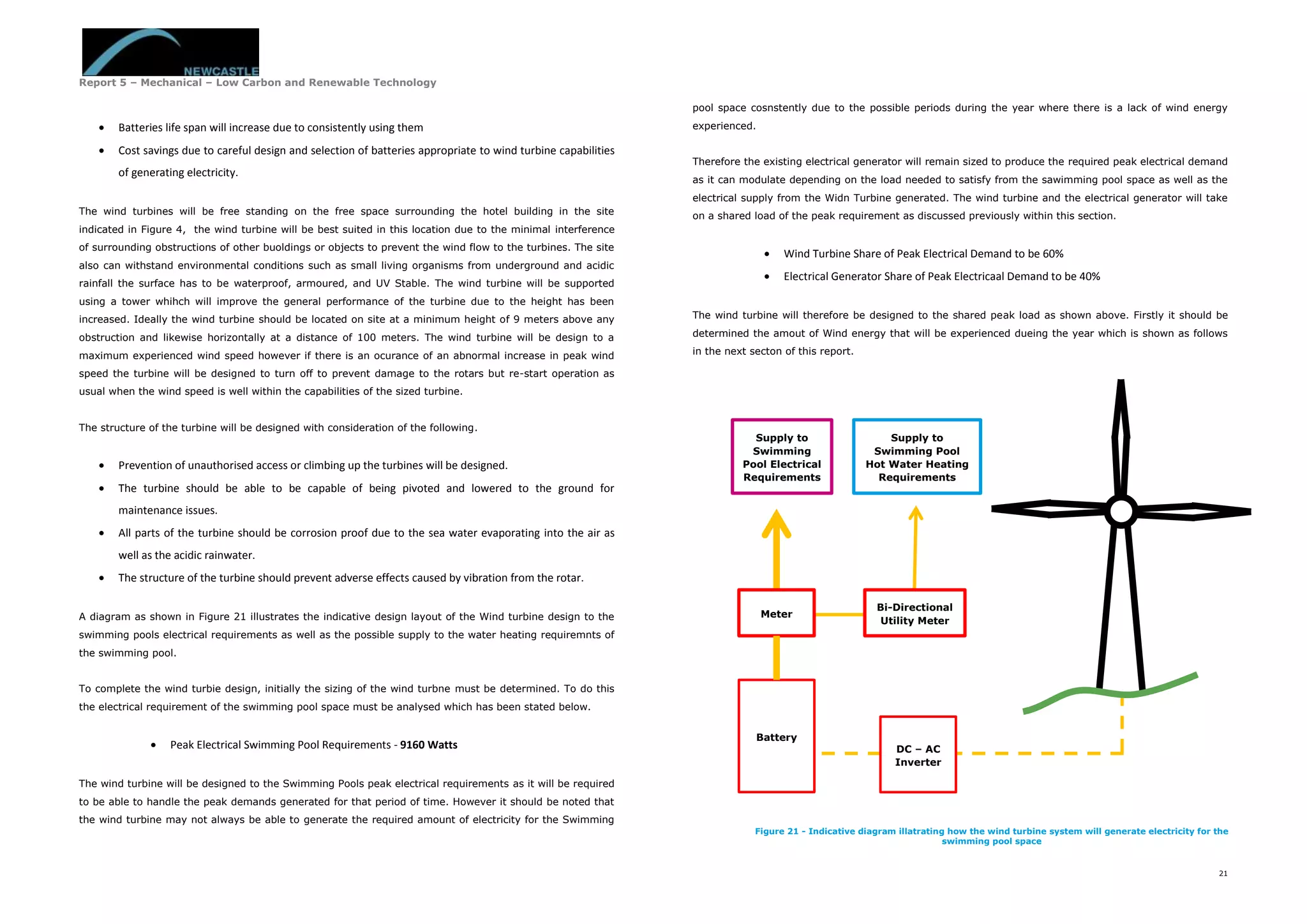

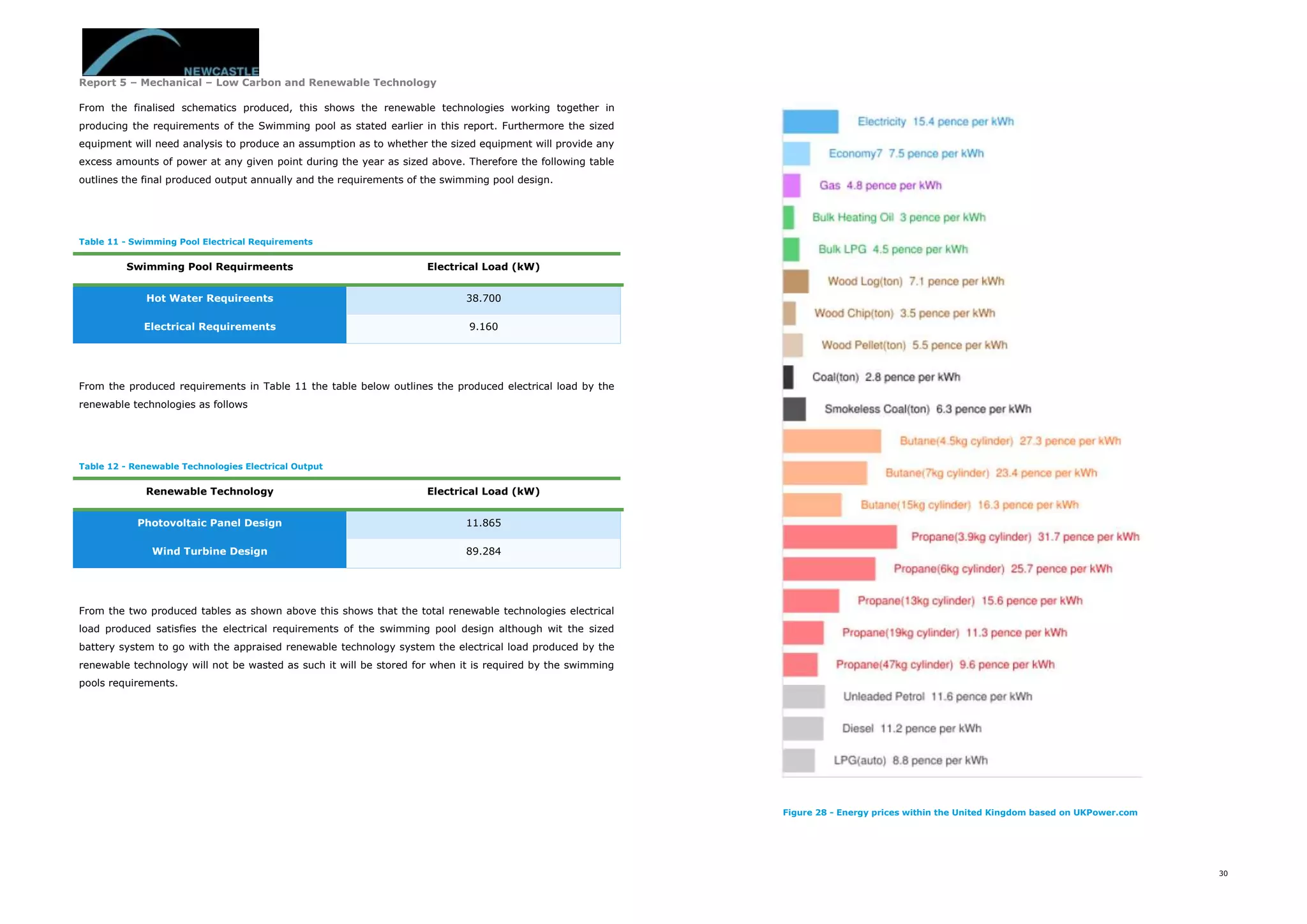

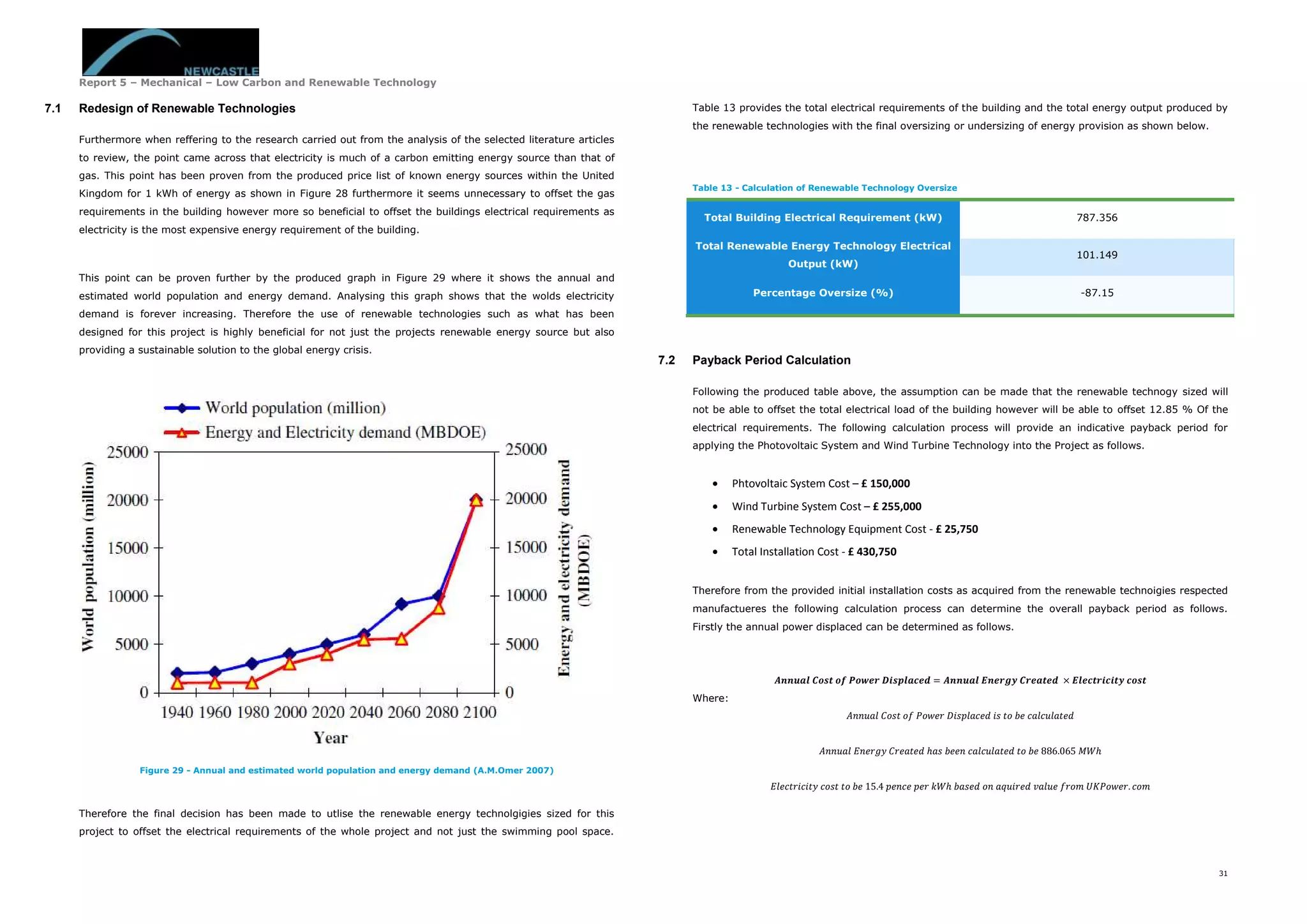

This document provides a literature review and analysis of renewable energy technologies that will be considered for a hotel project. It discusses photovoltaic panels, wind power, and the benefits of combining the two technologies. The review finds that photovoltaic and wind complement each other due to their intermittent nature. A methodology for optimizing hybrid photovoltaic-wind systems is presented. While renewable sources provide benefits, intermittency remains a challenge that requires energy storage or connection to the grid. The report will size renewable systems to power a hotel swimming pool, with the goal of minimizing energy dumping from the systems.