This document details the design of a backup PV system for a data center in Bogota, Colombia. Section I introduces the problem of weekly blackouts at the data center and the financial incentive to install a greener PV-storage backup system instead of a diesel generator. Section II discusses optimizing the panel tilt and azimuth for the location, determining the optimal configuration is 9 degrees tilt and 128 degrees azimuth. Section III analyzes the data center's load profile and effects of blackouts. Section IV provides details on selecting and sizing PV modules, charge controllers, batteries and inverters to meet the load requirements within constraints of the components.

![Fig. 3. Analemmas for different hours for the city of Bogota, showcasing

fairly stable 12 hours of sunlight throughout the year thanks to the city’s

latitude.

In order to correctly calculate the optimal panel tilt and

azimuth weather data has to be used. DNI, DHI and GHI

data for the whole year was obtained by using Meteonorm.

With it the Irradiance incident on the module can be obtained

following equation 1.

Gmod = Gdirect + Gdiffuse + Galbedo (1)

With Gdirect = DNI ∗ cos(AOI), where AOI is the

time-dependant angle of incidence (or Plane of the Array).

Gdiffuse = SV F ∗DHI according to the Isotropic sky model

[2]. Other, more precise models are available, but the Isotropic

model’s simplicity suits our hypothetical case well enough.

Finally, Galbedo = GHI ∗ α ∗ (1 − SV F), where α is the

albedo of the surrounding area, and SVF is the Sky View

Factor, described in equation 2.

SV F =

1 + cos(θM )

2

(2)

By integrating the radiance incident on the module for all

possible surface tilts and azimuths an irradiation profile is

obtained.

Figure 4 shows the irradiation profile for the city of Bogot´a.

It states that the maximum irradiation is obtained with a

surface tilt of 9 degrees and surface azimuth of 128 degrees.

Fig. 4. Optimization of the panel tilt and azimuth for Bogot´a, giving optimal

panel tilt and azimuth of 9 and 128 degrees respectively.

III. LOAD ANALYSIS

The load profile for the data centre was created by manipu-

lating the provided data, including the daily percentile pattern

and the monthly electricity bill. These were combined to create

the hourly load profile for the whole year, peaking at 8.5 kW

during the day, while dropping to around 6 kW at night. A

sample of the first day of each month is shown in figure 5.

Note the near zero difference between months; while there

are differences between each month in terms of total energy

consumption, these variations are too small to show up in the

final load pattern.

Fig. 5. A sampling of the load profile for the first day of each month. The

load peaks consistently at around 8.5 kW during the day, while bottoming out

at just over 6 kW during the night. Note the nearly complete absence of any

variation between months.

As stated in the assignment, a blackout occurs every week,

at which point the data centre moves away from its normal

load profile and switches to its critical load. The PV portion

of the system will not work during blackouts, even if they

2](https://image.slidesharecdn.com/datacentrepvbackupsystemdesign-200630193427/75/Design-of-PV-backup-system-for-data-center-2-2048.jpg)

![happen during the day. A simulink model of the system was

developed to simulate these situations.

A visual representation is shown in figure 6, with the

critical load shown in orange. While the blackout is supposed

to occur at random on the same day each week, for the

implementation in the model, 10 AM was chosen, as it

would take away the most time from the PV system

to recharge the battery/provide support for the nominal

load. This, coupled with a potential week with low solar

irradiance due to cloud coverage would constitute a worst

case scenario.

Fig. 6. One typical week of load for the datacentre. The blackout occurs at

10 AM on Sunday, as indicated in red, lasting for 7 hours. At this time, the

load decreases to maintain just a critical load of 5.8 kW.

A key requirement is that the output of the PV system

cannot exceed the data center’s load at any time. Figure 7

show’s the net difference between the PV system and the

required load for the whole year. It shows how the system

is not oversized and complies with the constrains stated by the

client.

Fig. 7. Load not supplied by the PV system throughout the whole year.

IV. PV DESIGN

In this section, the process of designing the back-up PV

system for a data center in Bogota, Colombia is described

separately for each system component.

A. PV modules/array

After considering the location properties and calculating the

optimal tilt angle and orientation in section II, the temperature

model of Sandia, described in [1], is used to calculate the

efficiency of the given two modules. The first module, the

Cheetah 72M 380-400 Watt, is found to give the best

performance. Even though the temperature coefficients are

almost the same for both modules, and the second module has

higher STC values, the second module (Cheetah 72M 390-410

Watt half-cell) has double the number of cells and thus, the

effect of any temperature increase is more severe and yields a

lower output. The area of the chosen module is 1.98 m2

.

Based on the load analysis discussed in section III

and after including all the efficiencies in the system (PV

module, charge controller and inverter), the maximum

number of modules is found to be 21, more than that

and the PV output would exceed the load. Considering

the charge controller limitations (discussed in subsection

IV-B1) 18 modules were chosen for a system of 3 charge

controllers.

This number of panels provides sufficient amount of energy

to fully charge the batteries before the blackout and able to

maximally support the grid (increase the saving) during normal

operation. Additionally, in this configuration there is a room to

expand the system by 6 extra modules with the same number

of inverters, if the constrains of the system change and some

cabling changes are permitted.

Since the location is a valley with a horizon free of

obstacles, the row to row shading is considered for a roof area

of 170 m2

. Due to the fact that the cable connection cost

is very low, the shading free time window taken during

winter solstice (the 21st of December) is from 7 am to

5 pm. For this period, the module spacing is found to

be 3.2516 m and the total area is 58.6462 m2

for 3 by 6

arrangement. This gives a Ground Cover Ratio (GCR) of

0.6086 (total area/PV area).

B. BoS components

1) Charge Controllers (MPPT): Two charge controllers

were given as options for the system: the Conext MPPT 60-

150 and the Conext MPPT 80-600. Table IV-B1 displays the

most important parameters for each model.

TABLE I

CHARGE CONTROLLER PARAMETERS

Model Pmax IarrSC VstrOC Io max η48V Cost

60-150 3500W 48 A 150 V 60A 98% 530e

80-600 4800W 28 A 550 V 80A 96% 1200e

For this system the Conext MPPT 60-150 will be used,

primarily due to its low cost. Our 18 PV panel configuration

3](https://image.slidesharecdn.com/datacentrepvbackupsystemdesign-200630193427/75/Design-of-PV-backup-system-for-data-center-3-2048.jpg)

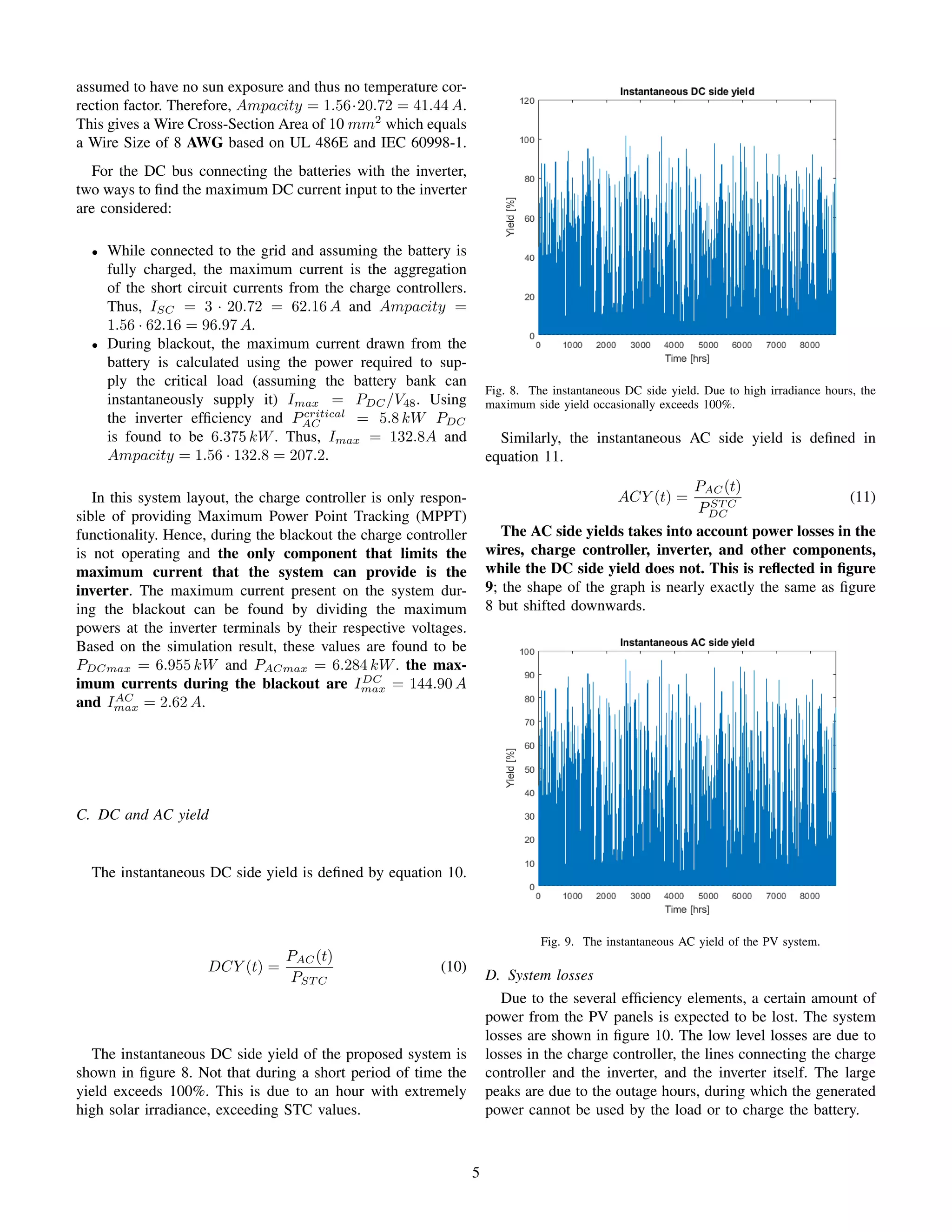

![Fig. 10.

Dividing the total losses by the raw output of the PV panels,

the total fraction of energy lost lies at around 10%. Most of

these losses are incurred in the inverter and during the outage

hours.

E. Cost analysis

Table IV-E lists the given prices for all the system compo-

nents, either by installed Wp or number of units. Using the

values provided, the overall cost of the system is e33,298.

This accounts for 18 PV panels (7200 Wp), 36 batteries, 3

charge controllers (type 1) and 1 inverter, plus switchgear

(assumed to be 1 of each).

TABLE III

ASSOCIATED COST FOR EQUIPMENT

Equipment Cost e/Wp Cost e/Unit

Solar panels 0.87 -

Hybrid Inverter 0.64

Mounting Structure - 32

Charge Controller 1 - 530

Charge Controller 2 - 1200

Battery - 430

DC/DC Switchgear - 370

AC/AC Switchgear - 450

Accessories 0.55 -

Table IV-E lists the cost of electricity and outage compensa-

tion per client for the data center. According to our model, our

system generates a total of 5598.1 kWh of electricity saved

per year, or an equivalent of e1119.62 saved per year.

Assuming 100% component reliability, and that the blackouts

occur at the same day of the week for up to 7 hours, the system

is guaranteed be able to supply the critical load throughout the

year. This means that the client avoids having to pay up to

e49140 in compensation costs.

This bring total savings to e50259.62 per year of operation.

TABLE IV

ASSOCIATED COSTS FOR ELECTRICITY AND OUTAGE COMPENSATIONS.

Location N. clients Compensation e/h Elec. price e/kWh

Bogot´a, CO 45 3.00 0.20

In terms of savings, the prevention of not providing the

critical load is the most significant. This saving alone easily

justifies the e33,298 investment for the PV storage system.

Furthermore, the PV system cuts down on the electricity bill by

supplying energy to the load. The long lifetime of the system

justifies the sizing.

According to our simulations, there are economies of scale

in relation to the system’s size (limited by the constrain of not

exceeding the building’s load). Table IV-E compares electricity

saving returns vs system cost for various configurations. Since

a bigger system also provides more critical load security, the

advantages of our configuration are apparent.

TABLE V

ELECTRICITY SAVINGS VS SYSTEM COST FOR VARIOUS CONFIGURATIONS

N. panels N. CC Elec. savings (10yr) Cost Relation

8 1 e2542.2 e23678 10.7%

16 2 e9476.8 e31056 30.5%

18 3 e11196.2 e33298 33.6%

V. CONCLUSION

In this report, the process of designing a back-up PV system

for a data center located in Bogota, Colombia was discussed

based on the provided constraints and components options.

To fully supply the critical load of 5.8 kW, 18 PV panels

of type Cheetah 72M 380-400 Watt from the manufacturer

Solar Jinko with 36 batteries of type 8A4DLTP-DEKA from

the manufacturer MK Battery are found to be the optimal

choice to save the company from a weekly 7 hour blackout.

The system requires three charge controllers of type ConextTM

MPPT 60 150 from the manufacturer Schneider Electric and

an inverter of type ConextTM

XW Pro for North America from

the same manufacturer.

Thanks to the high irradiance in Bogota, the DC yield of

the system exceeds a 100% of the standard DC output power

during the summer period. Even after subtracting the lost PV

output power due to the regular blackout, the system is still

prolific enough to provide a total saving of e50259.62 per

year. Therefore, beside the environmental benefits, the system

has a strong business case by having an attractive Return On

Investment (ROI) of only 0.60 years.

REFERENCES

[1] Kanyawee Keeratimahat, A.G. Bruce, J.K. Copper, et al.

“Temperature estimation of an unconventional PV array

using the sandia module temperature model”. In: Bris-

bane: Asia Pacific Solar Research Conference. 2015.

[2] P.G. Loutzenhiser et al. “Empirical validation of models

to compute solar irradiance on inclined surfaces for build-

ing energy simulation”. In: Solar Energy 81.2 (2007),

pp. 254–267.

6](https://image.slidesharecdn.com/datacentrepvbackupsystemdesign-200630193427/75/Design-of-PV-backup-system-for-data-center-6-2048.jpg)