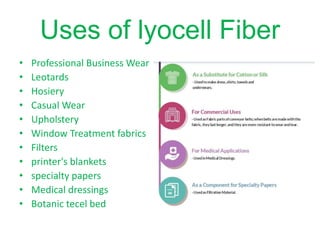

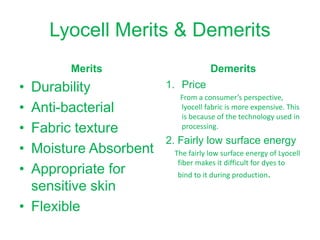

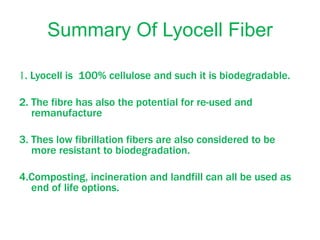

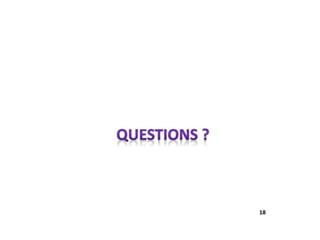

The document presents an overview of lyocell fiber, including its manufacturing process, properties, environmental impact, and applications. Lyocell is a biodegradable cellulose fiber known for its strength, versatility, and softness, making it suitable for various textile uses. It also discusses the merits and demerits of lyocell compared to cotton, emphasizing its durability and higher cost due to processing technologies.

![Introduction

• Lyocell is a form of rayon.

• It consists of cellulose fibre, made from

dissolving pulp and then reconstituting it

by dry jet-wet spinning.

• The fibre is used to make textiles for

clothing and other purposes

• Lyocell [Lyo from Greek lyein=dissolve &

Cell= from cellulose]

• The lyocell process was developed in

1972 by a team at the now defunct](https://image.slidesharecdn.com/southeast-200930105221/85/Regenerated-fibre-lyocell-3-320.jpg)