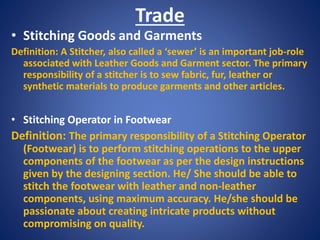

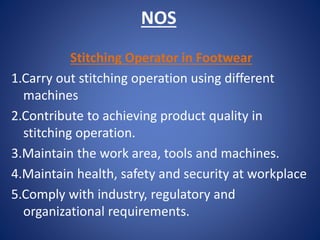

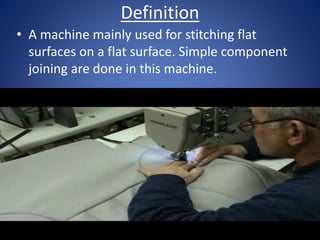

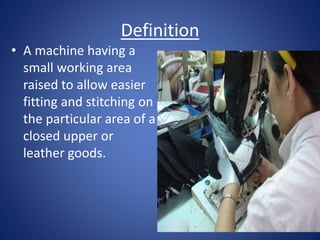

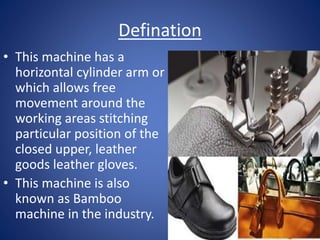

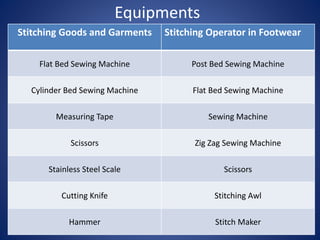

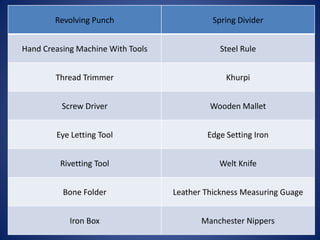

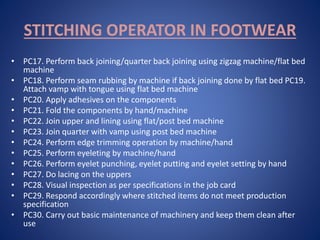

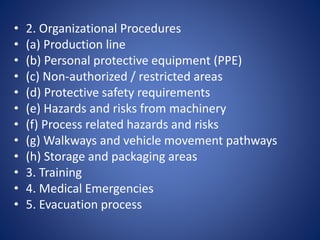

This document provides information about a Master Trainer in leather trades. It defines two trades - stitching goods and garments and stitching operator in footwear. It lists the national occupational standards and tasks for each trade. It also describes the different types of stitching machines used, required equipment, and health and safety considerations for the trades.