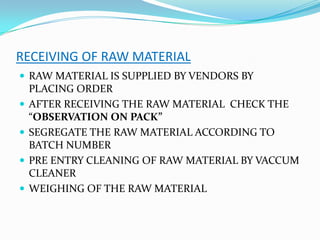

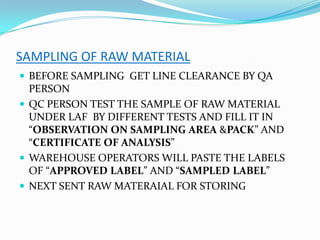

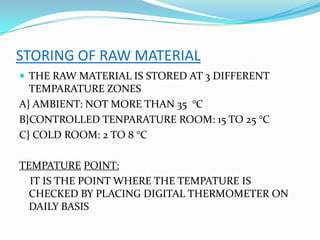

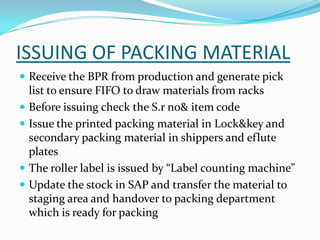

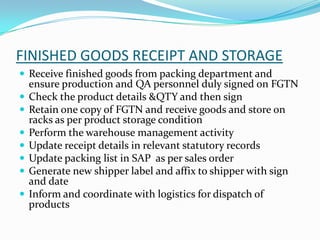

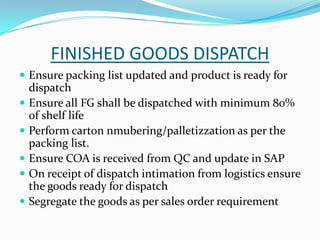

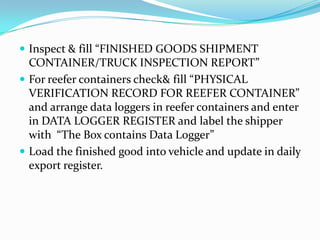

This document outlines the procedures for receiving, storing, dispensing, and shipping raw materials and finished goods at a warehouse. Raw materials are received and sampled before being stored in temperature controlled zones. Materials are dispensed according to a pick list and on a first expiry first out basis. Finished goods are received from production, stored, and then dispatched according to sales orders while ensuring minimum shelf life requirements are met.