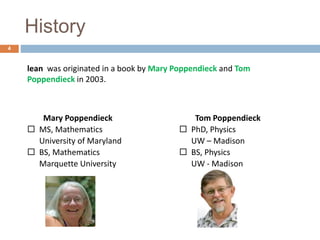

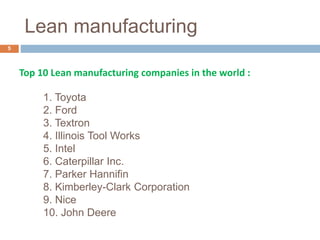

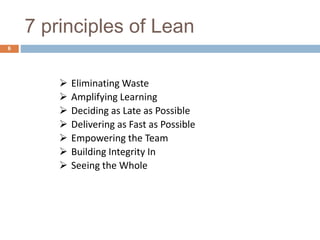

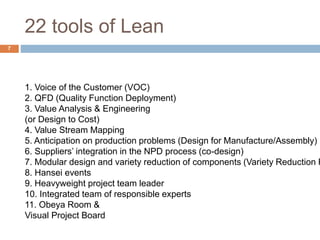

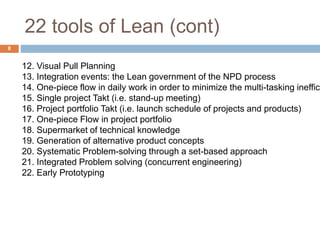

The document presents an overview of lean software development, highlighting its definition, historical background, principles, and tools. It details the advantages and disadvantages of lean methodologies, emphasizing the importance of minimizing waste and enhancing productivity. The conclusion reiterates the core goals of lean software development, which include the elimination of waste and improvements in efficiency and profitability.