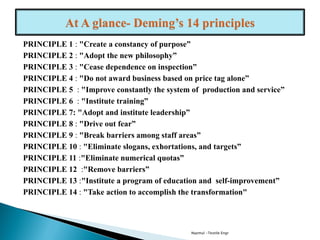

The document outlines key concepts in quality management, including definitions, the cost of quality, and principles from quality gurus like W. Edwards Deming and Joseph Juran. It highlights Deming's 14 Principles aimed at improving product and service quality through systemic changes and leadership. The training session emphasizes the adoption of a new philosophy in management and the importance of continuous improvement and teamwork in quality assurance.