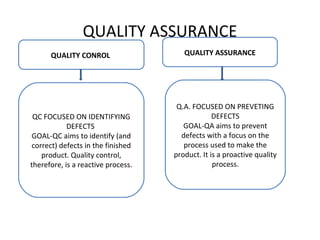

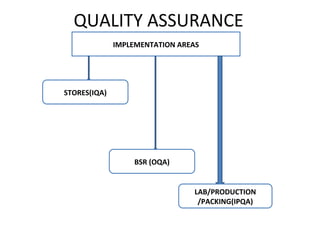

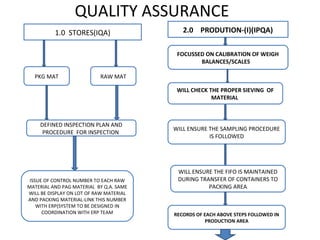

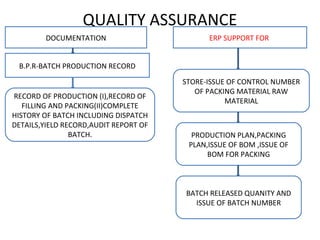

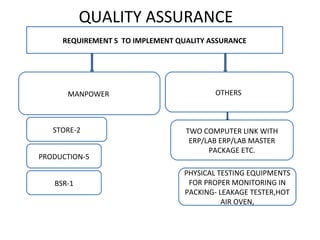

This document summarizes quality assurance and quality control processes. It discusses that quality control focuses on identifying defects in finished products through reactive testing, while quality assurance aims to prevent defects through a proactive process focus. It then outlines the implementation of quality assurance in various areas including stores, production, packing, and batch storage and release. Key activities involve inspection planning, issuing control numbers, monitoring processes, sampling, testing, and record keeping. The goals are to control waste, enhance product quality consistency, and improve customer faith.