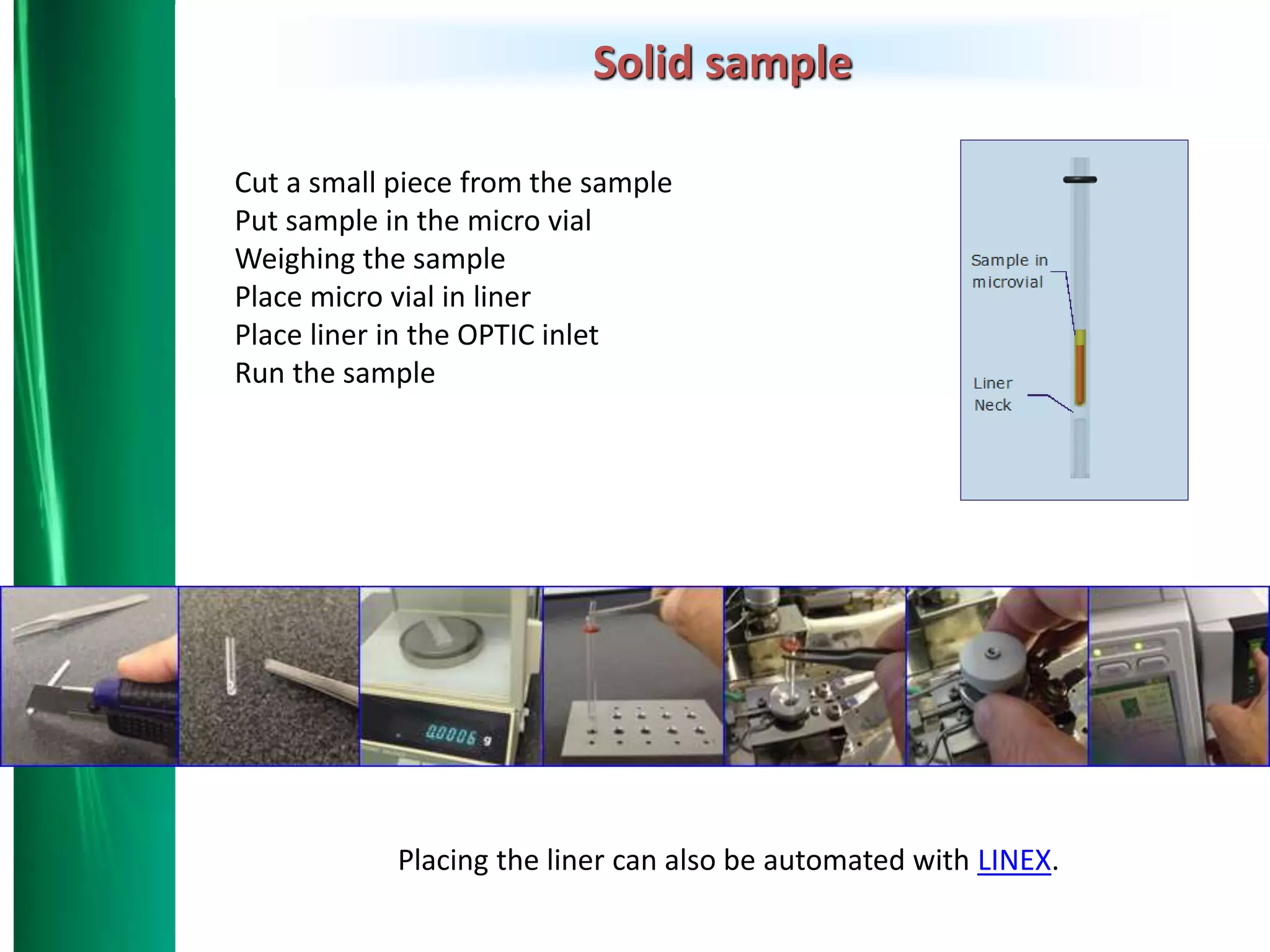

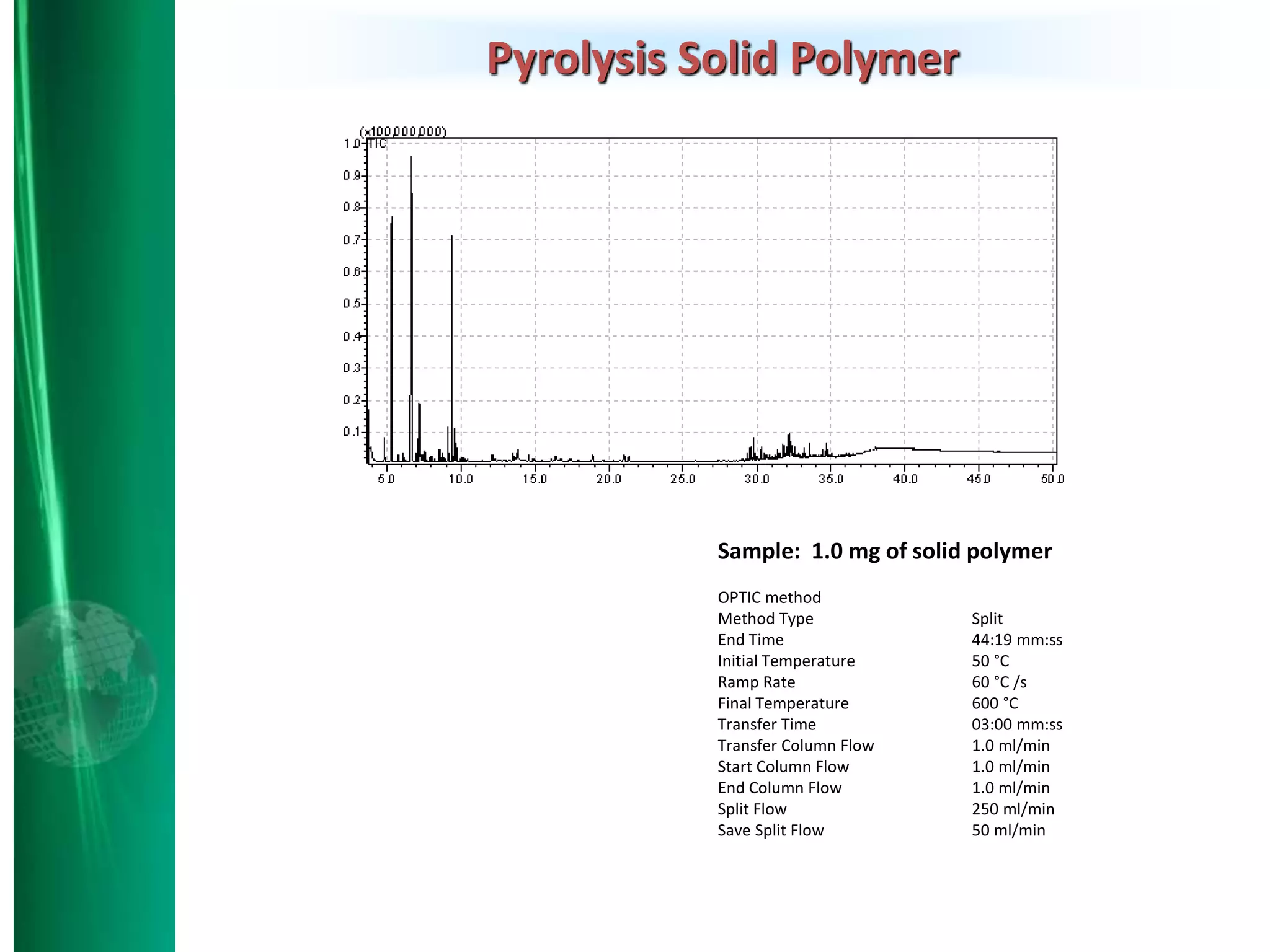

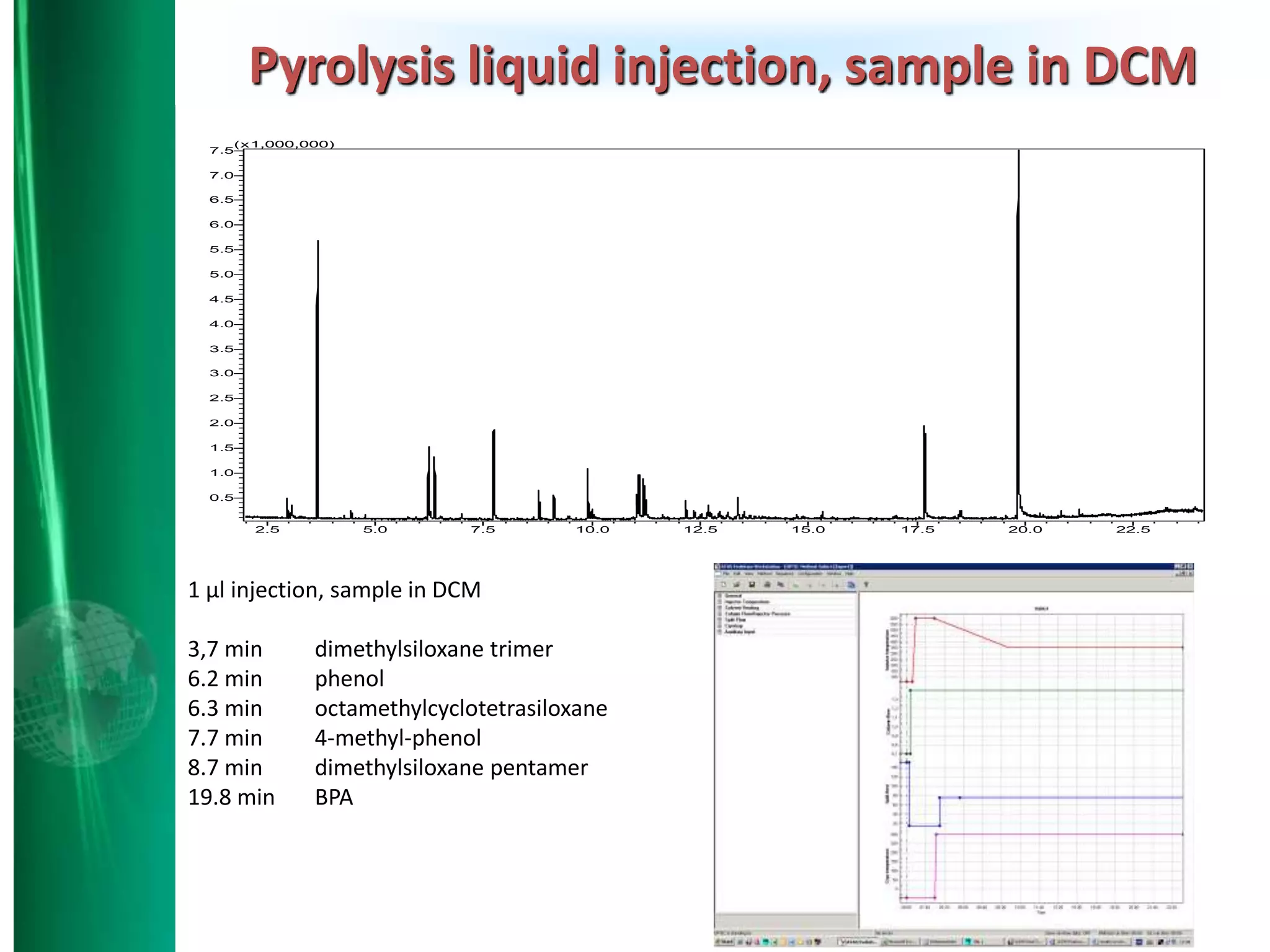

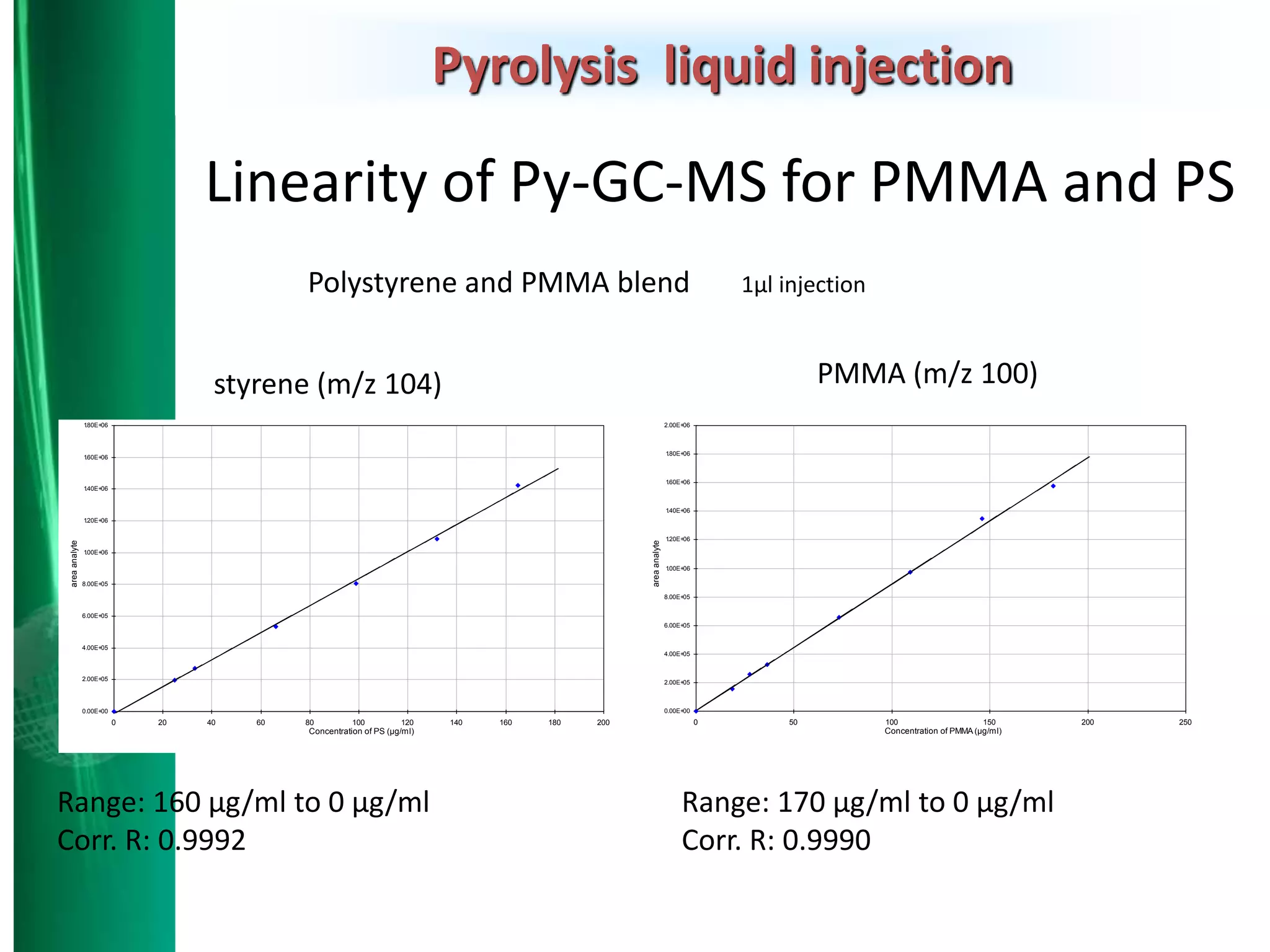

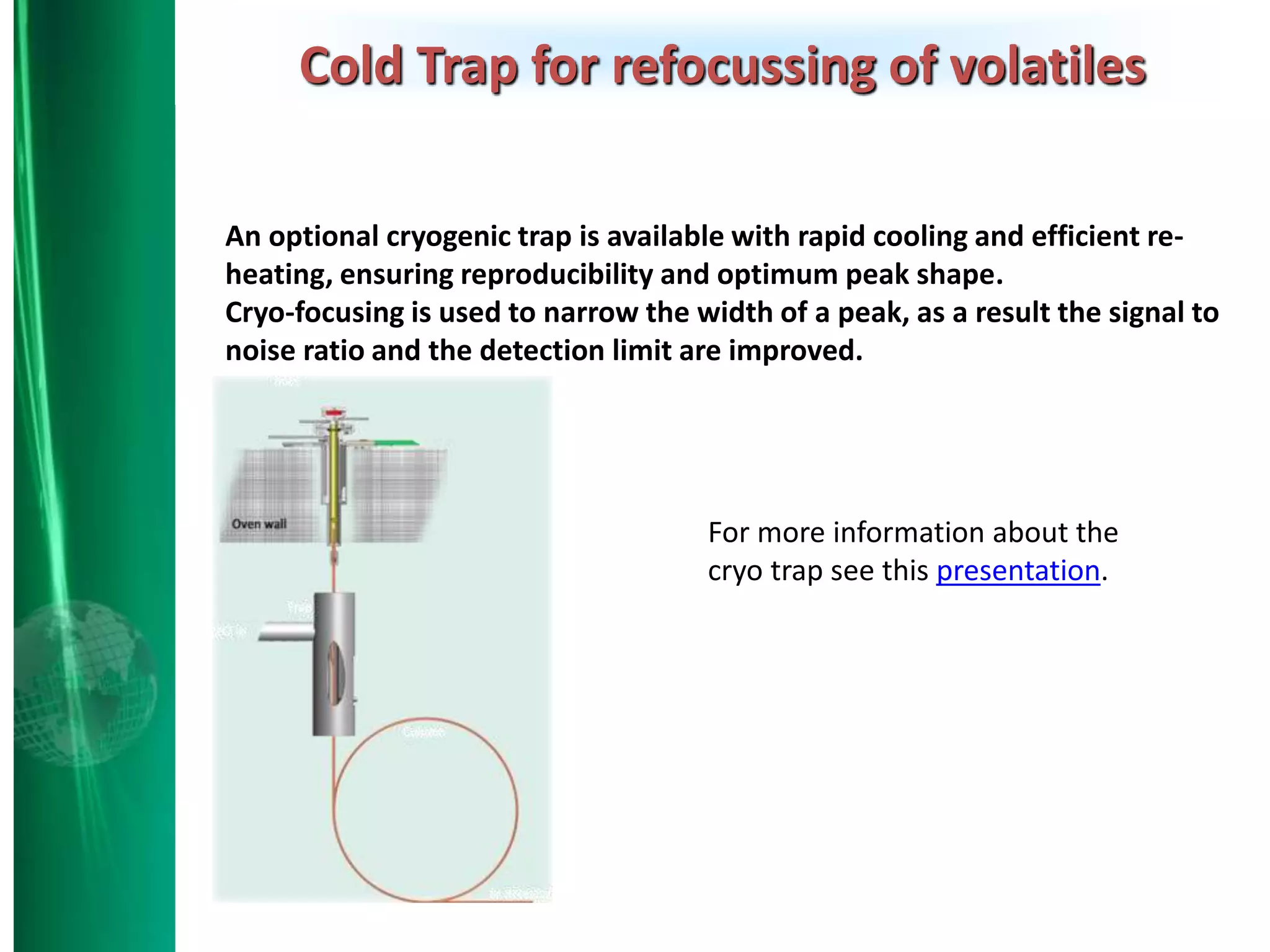

Pyrolysis is the breaking apart of chemical bonds through thermal energy. Analytical pyrolysis introduces solid and high molecular weight samples to a gas chromatograph by breaking them down. It is used to minimize sample preparation and analyze whole samples. Applications include forensics, polymers, and microorganisms. Samples are placed in a quartz tube or vial and pyrolyzed. Liquid samples can also be injected and pyrolyzed. The OPTIC inlet allows for fast, high temperature pyrolysis for both solid and liquid samples.