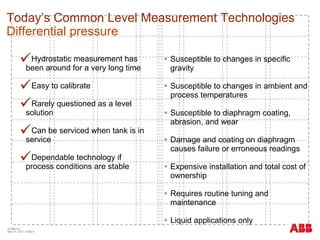

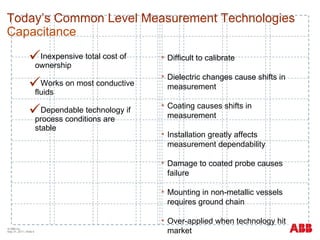

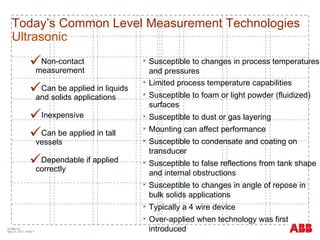

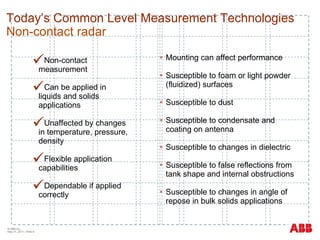

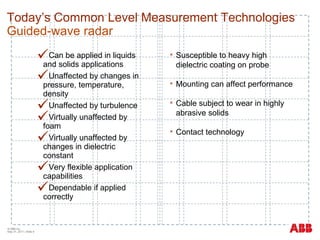

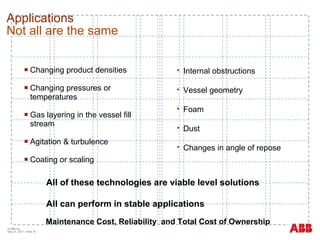

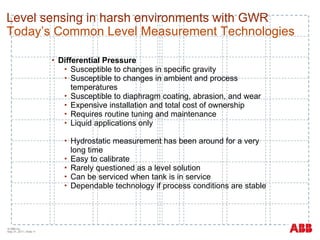

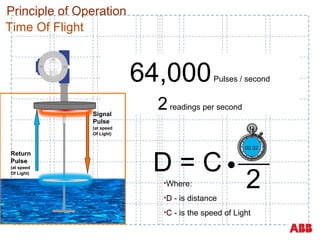

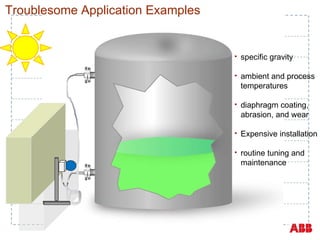

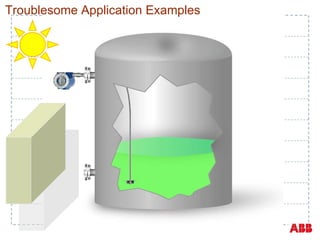

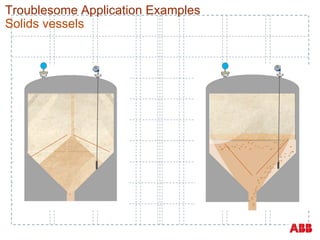

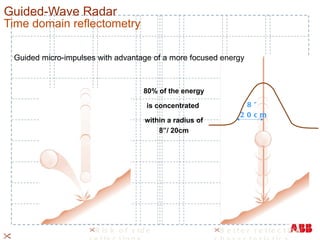

The document discusses level sensing technologies, particularly focusing on guided-wave radar (GWR) for use in harsh environments. It evaluates common methods such as differential pressure, capacitance, and ultrasonic measurements, highlighting their limitations and reliable applications. The talk aims to explain how GWR offers better reliability and performance in various challenging scenarios compared to traditional measurement techniques.